Planetary transmission structure

A technology of planetary transmission and planetary carrier, which is applied in the direction of transmission, transmission parts, gear transmission, etc. It can solve the problems of high requirements for heat treatment and processing, increased axial clearance of the sun gear, and poor results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

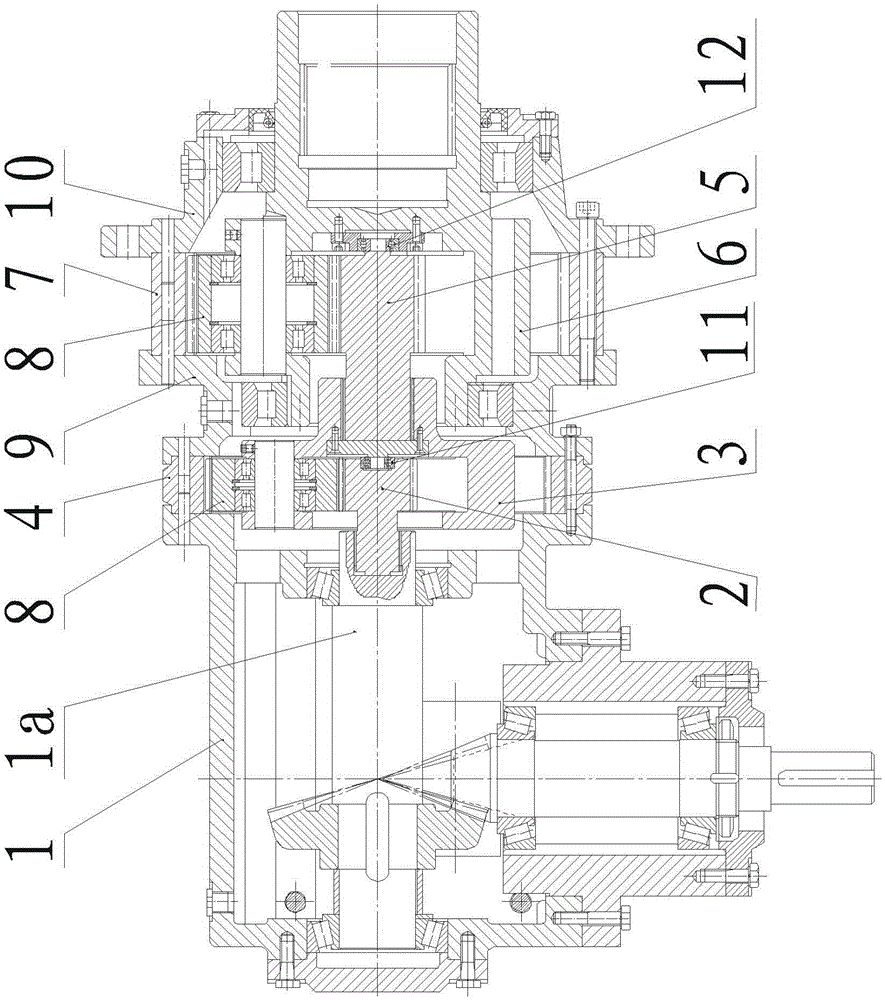

[0015] like figure 1 The shown planetary transmission structure includes a single-stage bevel gear box 1, a first sun gear 2, a first planet carrier 3, a first internal gear 4, a second sun gear 5, a second planet carrier 6, a second internal gear Gear 7, the first planet carrier 3 and the second planet carrier 6 are equipped with planetary gears 8, the first internal gear 4 and the second internal gear 7 are connected by a connecting support 9, the second The other end of the internal gear 7 is equipped with a connecting flange 10. The single-stage bevel gearbox 1 includes an output shaft 1a, and the output shaft 1a, the first sun gear 2, and the second sun gear 5 are located on the same axis. The front end of the first sun gear 2 is mounted on the output shaft 1a, a first bearing 11 is installed between the rear end of the first sun gear 2 and the front end of the second sun gear 5, and the outer ring of the first bearing 11 Fixed on the rear end face of the first sun gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com