Foldable valve handle system capable of adjusting torque

A torque-adjusting, folding technology, applied in valve details, valve device, valve operation/release device, etc., can solve problems such as inability to open, inconvenient operation, valve rust, etc., to save resources, facilitate storage, and reduce torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

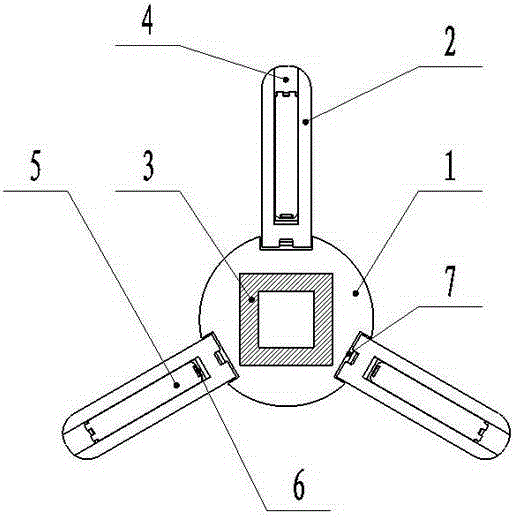

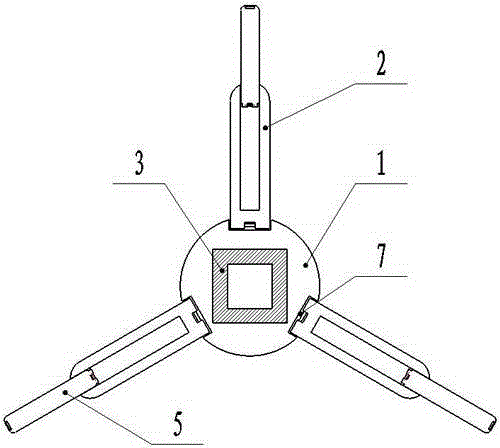

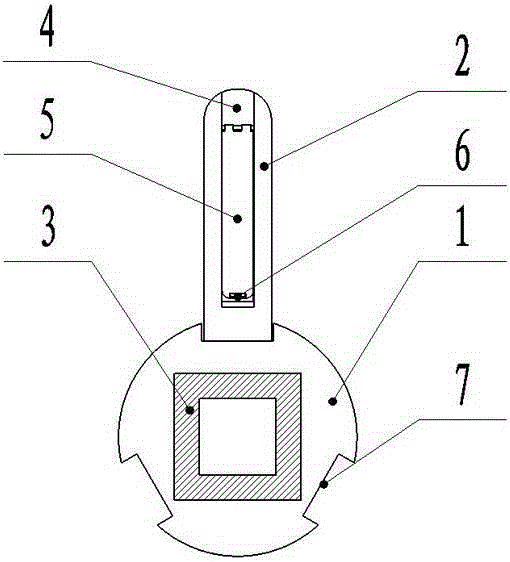

[0028] Such as Figure 1-2 As shown, the present invention is a foldable and torque-adjustable valve handwheel system, which includes a wheel 1 and a wheel handle 2. There are three grooves 7 arranged in an annular array on the outer side of the wheel 1, and a wheel handle 2 is arranged in the groove. , a groove 7 is provided on the roulette 1, and the roulette handle 2 can also be folded, which can be adapted to operate in a narrow space and is convenient for storage. There is a square hole in the middle of the roulette 1, and a valve stem ferrule 3 is installed in the square hole; a strip groove 4 is arranged on the roulette handle 2, and a folding handle 5 is arranged in the strip groove 4, and the folding handle 5 is hinged in the strip groove 4. The section of the strip groove 4 is concave or arc-shaped.

[0029] When using, select a suitable valve stem ferrule 3 according to the shape and size of the valve stem, and then insert it into the square hole of the wheel 1. W...

Embodiment 2

[0031] Such as Figure 1-2 As shown, the present invention is a foldable and torque-adjustable valve handwheel system. On the basis of Embodiment 1, the front end of the foldable handle 5 is provided with an opening groove 6 . It is convenient to pull open the folding handle 5 .

Embodiment 3

[0033] Such as Figure 1-2 As shown, the present invention is a foldable and torque-adjustable valve handwheel system. On the basis of Embodiment 1, the foldable handle 4 is covered with a rubber sleeve. One is to be convenient to hold and anti-slip, and the other is to be convenient to be stuck in the strip groove 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com