Membrane splitting pair for manufacturing PTFE fibers

A technology of PTFE and film splitting, which is applied in fiber processing, complete sets of equipment for producing artificial threads, textiles and papermaking, etc. It can solve the problems of high labor intensity, affecting the performance of finished products, and low production efficiency, so as to improve safety and service life. , improve quality and performance, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

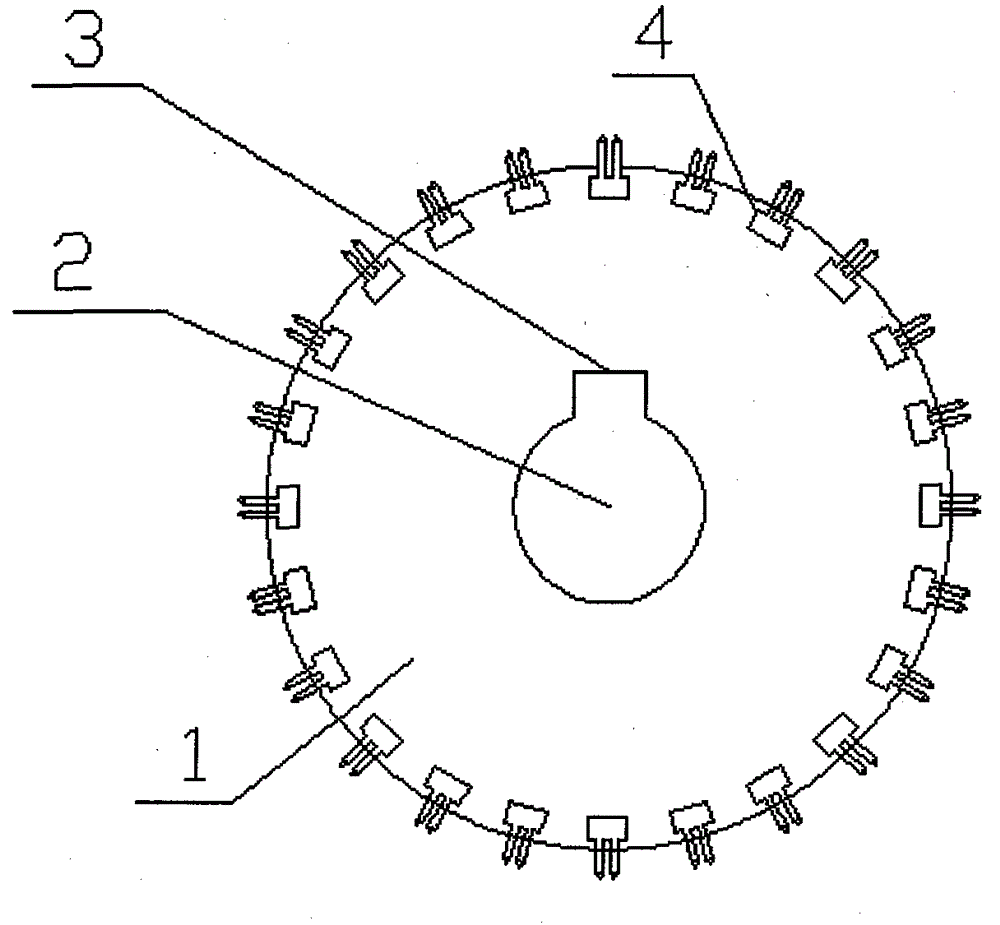

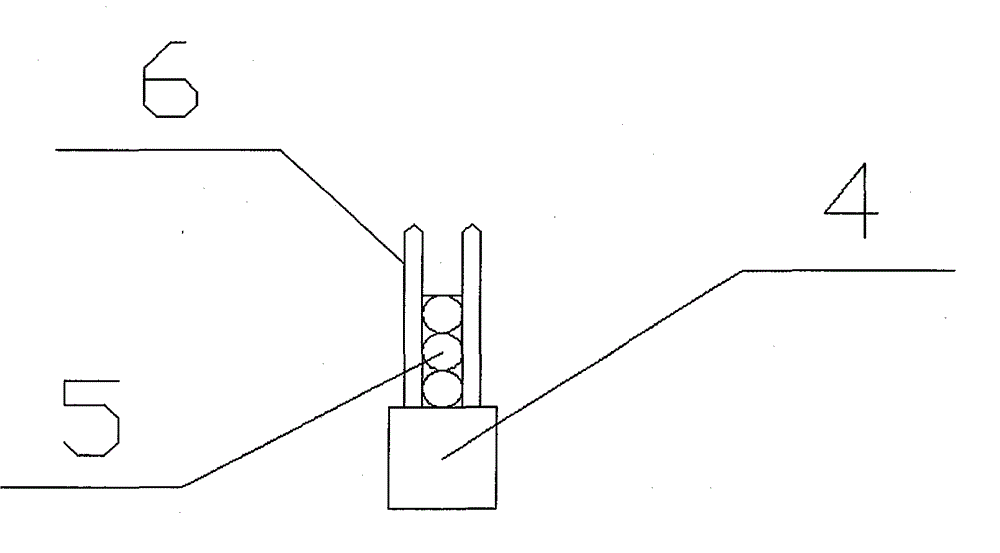

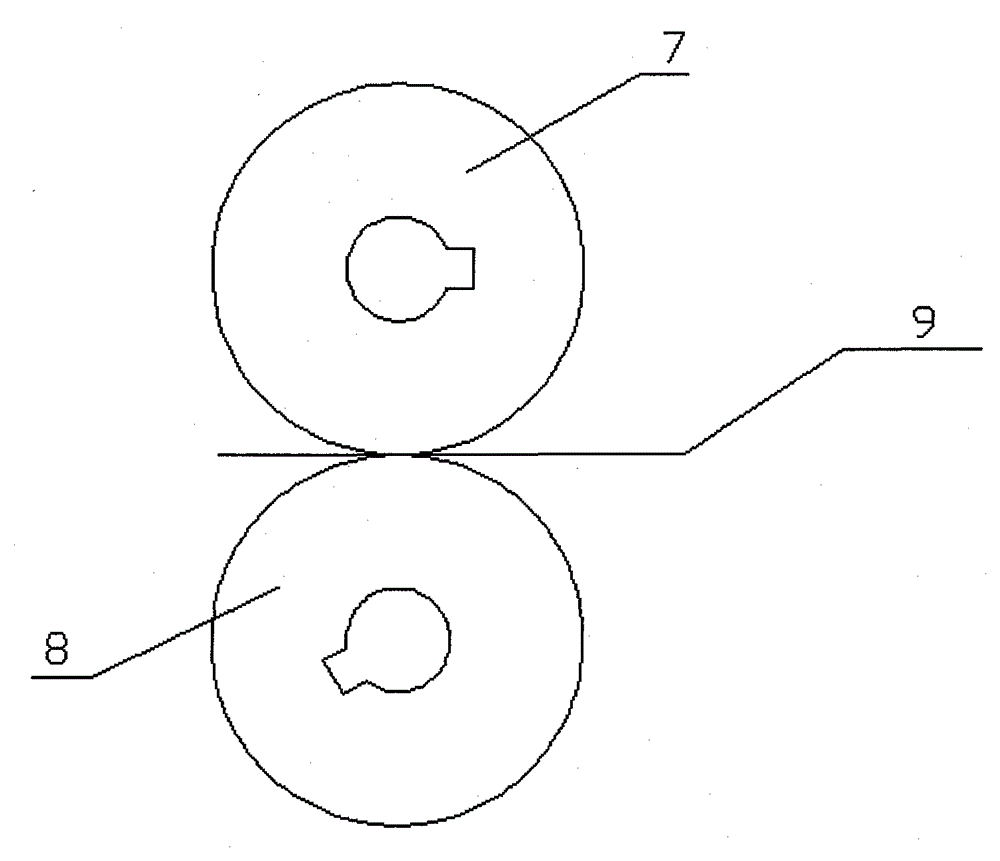

[0028] see picture 1 -4, Ben invention A technical solution is provided: an iron comb-type film splitting pair for manufacturing PTFE fibers, which includes a film splitting roller 1, and the film splitting rollers 1 are set to two, respectively, the upper splitting film roller 7 and the lower splitting film Roller 8; Two described film splitting rollers 1 cooperate to use up and down; PTFE film 9 is arranged between upper splitting film roll 7 and lower splitting film roll 8; In the cavity 2 connected to the rotating shaft and the fixed key 3 arranged on one side of the cavity 2, each of the film splitting rollers 1 is fixed with a groove 10 that matches the iron comb base 4, and the iron comb base 4 is fixedly installed with two rows of iron combs 6, and a fixed bar 5 is arranged between the two rows of said iron combs 6, and said iron combs 6 are formed by uniform arrangement of heat-treated steel needles. The number of the steel needles on each of the iron combs is set...

Embodiment 2

[0031] as shown in the picture 5 to picture 8 As shown, this invention A needle-type splitting pair for manufacturing PTFE fibers, including a splitting roller 21, a slider groove 22, a steel needle 23, a groove 24, a slider 25, a spacer 26 and a PTFE membrane 27, each splitting The pair is composed of two upper and lower film splitting rollers 21; each film splitting roller 1 is evenly provided with slider grooves 22, and there are twenty-four slider grooves 22 in total; the film splitting rollers 21 are made of carbon steel after heat treatment. The heat-treated carbon steel greatly improves the life of the device and the stability during use. The steel needle 23 is fixed on the slider 25, and the steel needle 23 is provided with two rows on the slider 25 and each row The number is 95, which greatly improves the work efficiency, and at the same time improves the quality and performance of the product. The groove 24 is arranged under the slider 25, and the slider 25 is ...

Embodiment 3

[0034] see picture 9 -10, the present invention provides a technical solution: a splitting pair for manufacturing PTFE fibers in the present invention, including a splitting roll 31, and the splitting roll 31 is set to two, respectively the upper splitting roll 3101 and the splitting roll 3101 The lower film splitting roller 3102; the two film splitting rollers 31 are used together up and down; the PTFE film 32 is arranged between the upper film splitting roller 3101 and the lower film splitting roller 3102; each film splitting roller is evenly arranged with several The thorns 33, the thorns 33 on the upper film splitting roller 3101 and the thorns 33 on the lower film splitting roller 3102 are alternately arranged, and each film splitting roller 31 includes a set in the middle of the film splitting roller 31 for connection The cavity 34 of the rotating shaft and the fixed key 35 arranged on one side of the cavity 34 . The thorn point 33 and the film splitting roller 31 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com