LED chip junction temperature testing method

A technology of LED chips and testing methods, applied in the field of semiconductors, can solve problems such as heat loss, insufficient switching speed of current source meters, and affecting test results, so as to avoid the impact of heat loss and reduce the cost of testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The LED chip junction temperature testing method of the present invention comprises the following steps:

[0018] (1) Modeling: Under the driving current, the LED chip collects the voltage values of the driving current at ambient temperatures such as 25°C, 40°C, 60°C, 80°C, 100°C, and 120°C; Aging current;

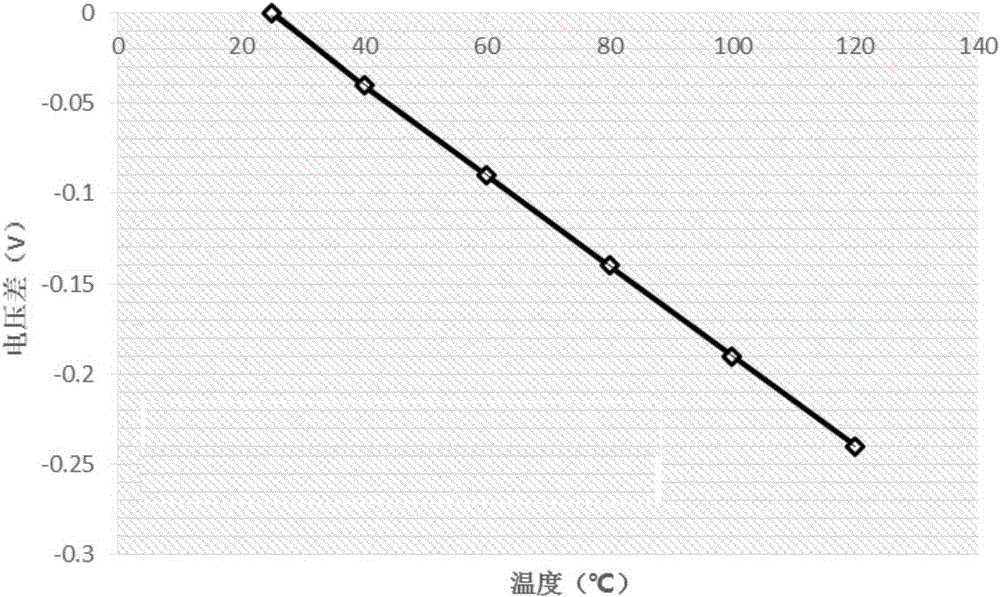

[0019] (2) Modeling calculation: According to the different temperatures obtained in step (1) and the corresponding voltage difference, make a table to obtain a function fitting formula y=ax+b, where x is the abscissa, representing the ambient temperature; y is the ordinate , represents the voltage difference; a is the slope, and b is the intercept; the linear function curve obtained in this embodiment is as follows figure 1 As shown, y=-0.002518x+0.061661;

[0020] (3) Actual measurement: use the driving current to drive the LED chip to the thermal equilibrium state, and obtain the voltage value under the thermal equilibrium state; the driving current is the ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com