Containment Propelling Construction Method Utilizing Guide Rail Section Steel

A technology of culvert and section steel, which is applied in the field of underground tunnel construction, can solve the problems of small friction and achieve the effect of preventing ground collapse and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

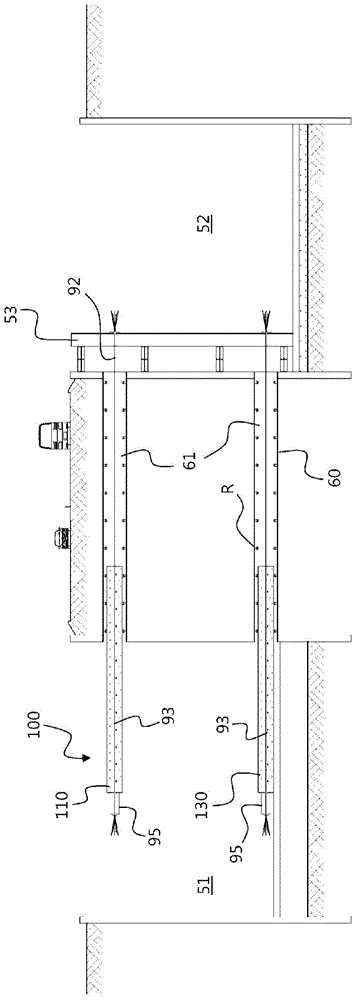

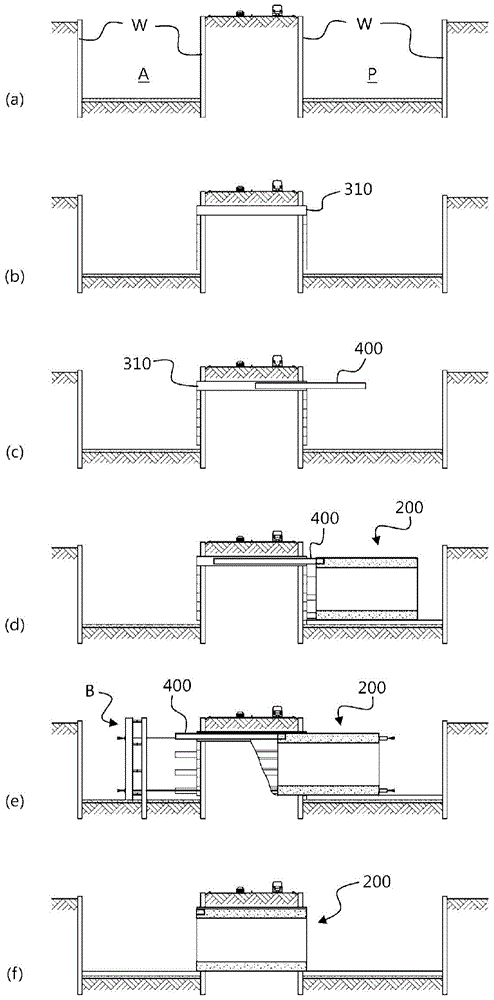

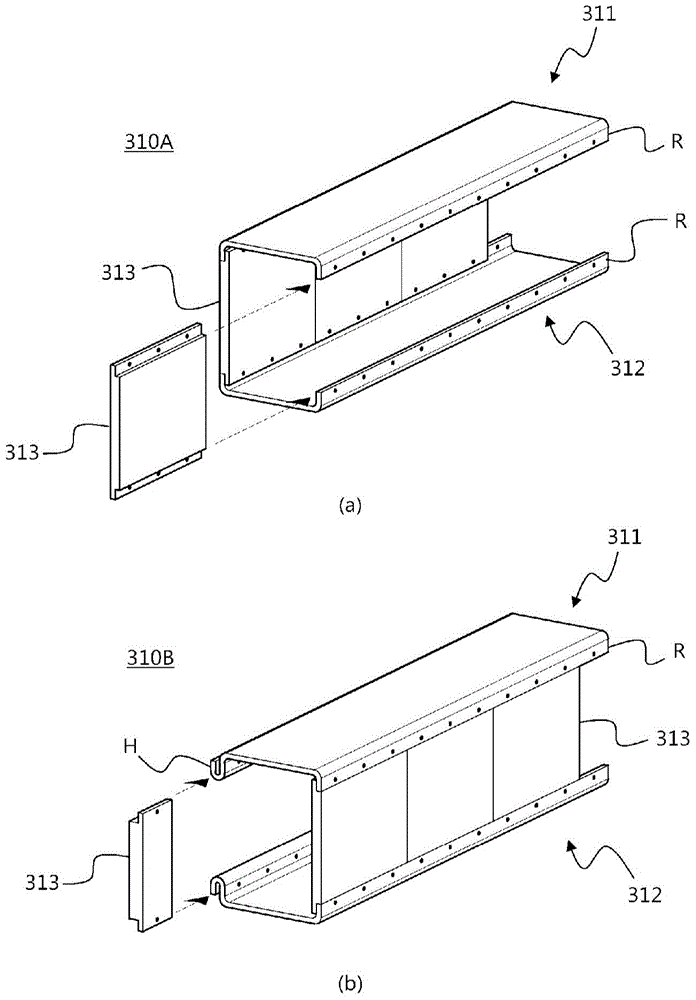

[0037]The culvert propulsion method of the present invention is used to construct an underground tunnel, and the above-mentioned culvert propulsion method is characterized in that it includes: step a, constructing a propulsion base before the section to be constructed of the underground tunnel, and constructing an arrival base after the section to be constructed of the underground tunnel ; Step b, driving a plurality of steel pipes corresponding to the positions to be constructed of the outer wall of the culvert body and the top plate, and removing the sand and soil inside the steel pipes to form a steel pipe composite; Step c, corresponding to the insertion position of the guide rail section steel After the rollers are set inside the composite body, insert the guide rail profile steel into the above steel tube complex; step d, manufacture the culvert body at the propulsion base, and make the end of the above guide rail profile steel and the culvert body join; step e, remove the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com