Phone cover glass gluing system

A glass gluing and glass technology, which is applied to coatings, devices that apply liquid to surfaces, etc., can solve the problems of low gluing efficiency and low yield on the edge of glass, and achieve yield guarantee, production improvement and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

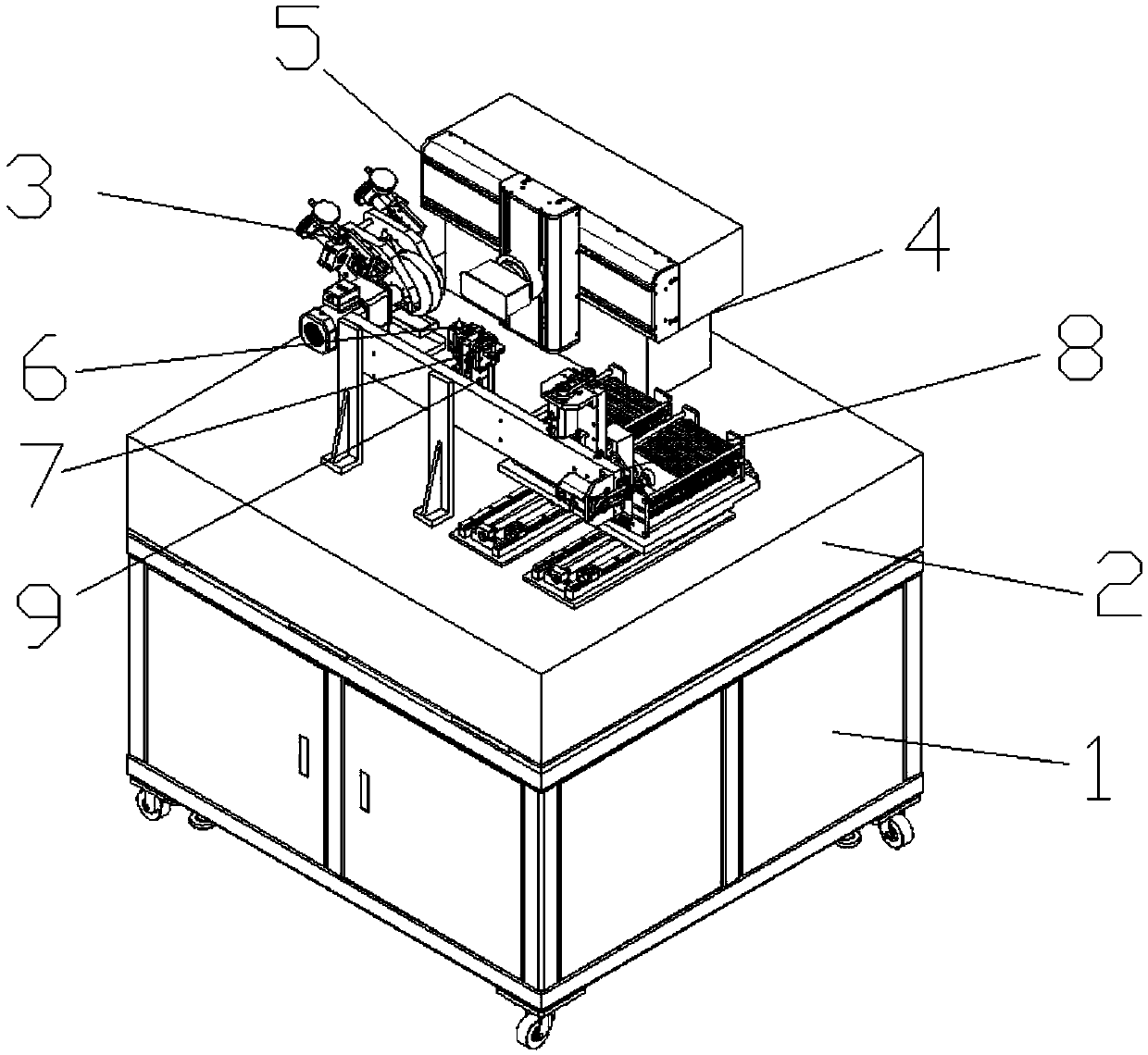

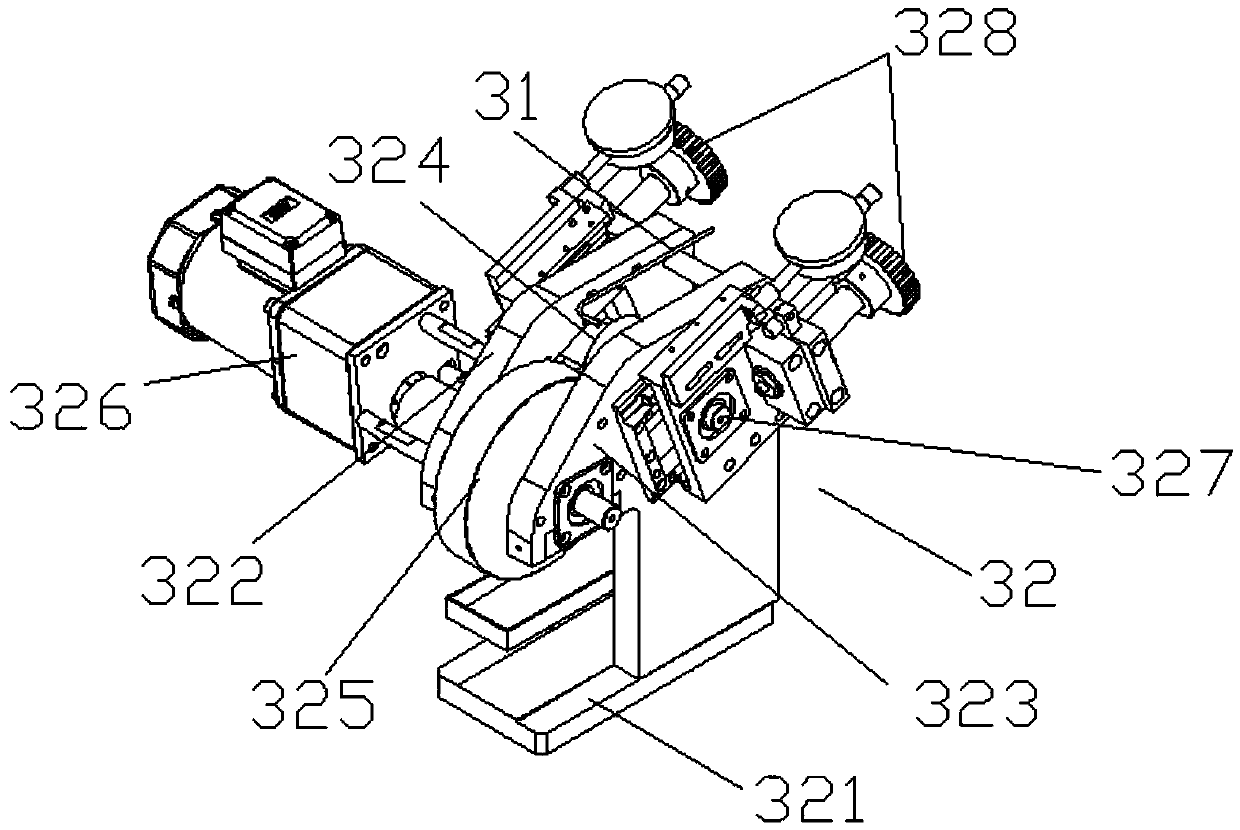

[0024] refer to Figure 1 to Figure 3 Shown, in the present embodiment, a kind of mobile phone glass gluing system comprises the workbench 2 that is installed on the fuselage frame 1, the dispensing mechanism 3 that is installed on the workbench 2 and the installation platform 4, and this installation platform 4 A glass clamping mechanism 5 is provided, and the dispensing mechanism 3 and the glass clamping mechanism 5 are controlled by an electric control device (not shown in the figure), wherein;

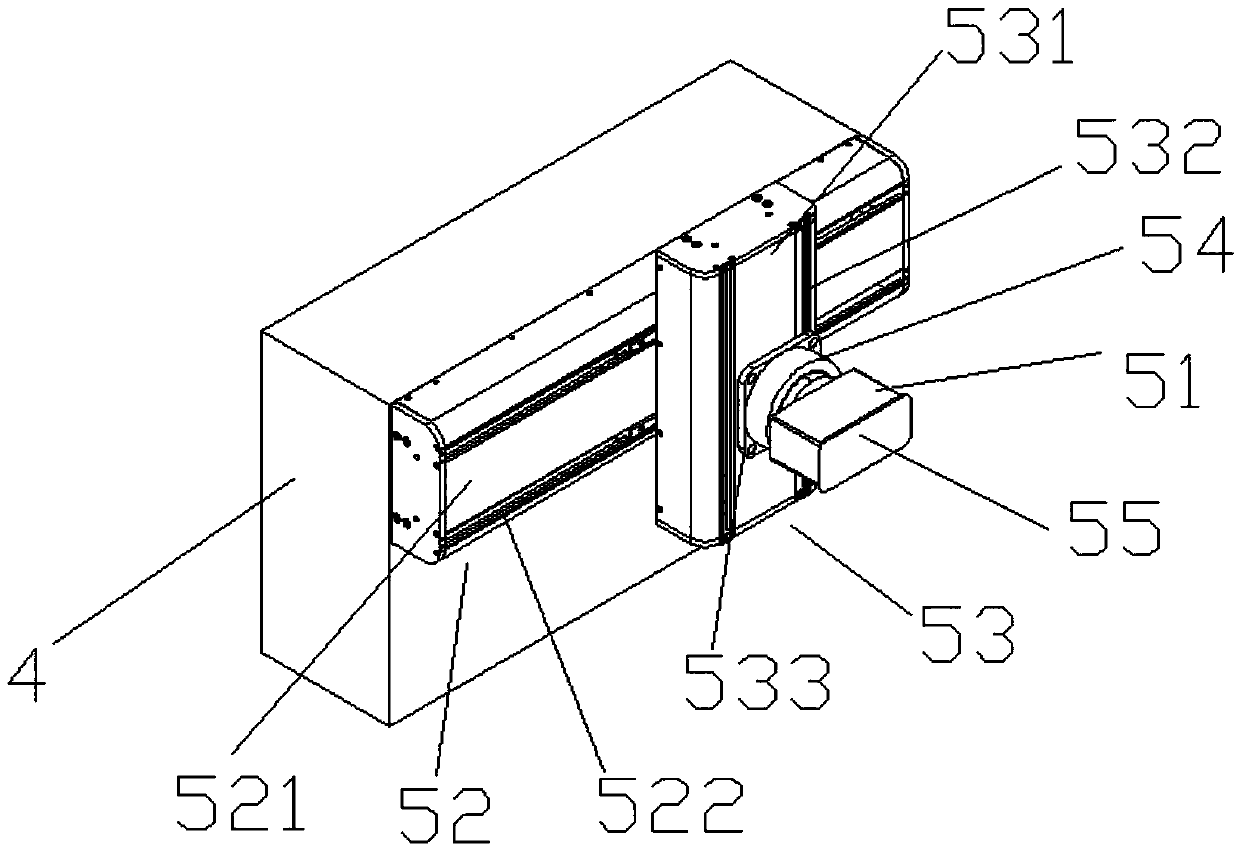

[0025] Glass clamping mechanism 5 comprises vacuum suction device 51, left and right moving device 52, up and down moving device 53 and rotating device 54, and left and right moving device 52 is arranged on the mounting table 4, and up and down moving device 53 is arranged on left and right moving device 52, and rotating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com