Dual-purpose fixing mechanism for cutting arc-shaped board

A fixed mechanism and arc-shaped plate technology, which is applied in the direction of clamping, positioning devices, metal processing machinery parts, etc., can solve the problems of unsuitable arc-shaped plate cutting on the operating table and unqualified finished products, so as to increase the scope of application and save investment The effect of cost and convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

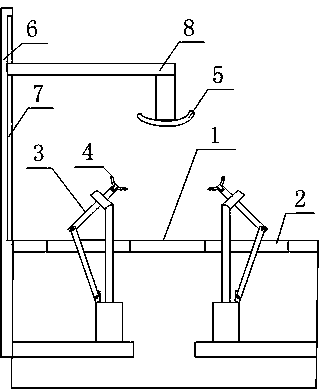

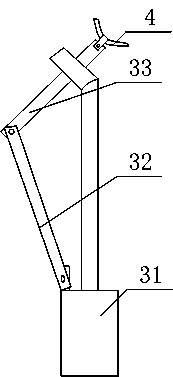

[0024] Dual-purpose fixed mechanism for cutting curved plates, such as figure 1 and figure 2 As shown, it includes an operation table body 1 with an operation platform. Two installation ports 2 are arranged on the operation platform. The straight line formed between the two installation ports 2 is in the same direction as the cutting movement direction of the arc-shaped plate. 2 are equipped with an angle adjustment part 3; the two angle adjustment parts 3 are symmetrically arranged, the angle adjustment part 3 includes a push cylinder 31, the bottom end is hinged on the fixed rod 32 on the cylinder body of the push cylinder 31, and the bottom end is hinged The moving rod 33 at the top of the fixed rod 32;

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that the example in this embodiment optimizes the specific structure of the angle adjustment part 3, such as figure 2 As shown, the specific settings are as follows:

[0027] The top end of the push-pull shaft of the push cylinder 31 is sleeved on the moving rod 33 ; the top end of the moving rod 33 is also provided with a cushion 4 .

Embodiment 3

[0029] The difference between this embodiment and Embodiment 1 is that: the operating table body 1 in this embodiment is also provided with a pressing device for pressing the curved cabinet door on the operating table body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com