Control Method of Fixing Mechanism for Dual-purpose Curved Plate Cutting

A technology of a fixing mechanism and a control method, applied in the field of control, can solve the problems of unqualified finished products, the operation table is not suitable for arc plate cutting, etc., and achieves the effect of saving input cost, increasing the scope of application, and widening the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The control method of the fixed mechanism for dual-purpose arc-shaped plate cutting includes:

[0029] (1) Place the arc-shaped plate of the distribution cabinet on the operation table between the two angle adjustment parts;

[0030] (2) Start the push cylinder on the angle adjustment part, so that the top of the moving rod is close to the arc plate of the distribution cabinet, and the arc formed between the arc plate of the power distribution cabinet and the operation table body and the top of the two moving rods is consistent with the The arc plates of the power distribution cabinet are consistent; press down the pressing device so that the arc plate of the power distribution cabinet is fixed between the pressing device and the angle adjustment part;

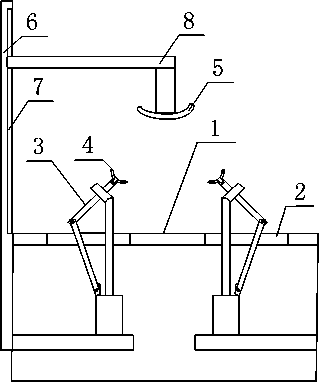

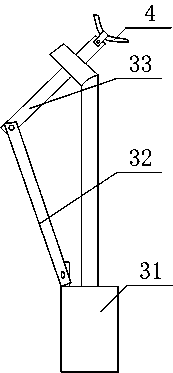

[0031] like figure 1 and figure 2 As shown, the angle adjustment part 3 includes a push cylinder 31, a fixed rod 32 whose bottom end is hinged on the cylinder body of the push cylinder 31, and a moving rod 33 whose b...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that: the operating table body 1 described in this embodiment is also provided with an installation port 2, and the specific settings are as follows:

[0034] The operating platform is provided with two installation ports 2, and the straight line formed between the two installation ports 2 is in the same direction as the cutting and moving direction of the arc-shaped plate, and an angle adjustment part 3 is installed in each installation port 2; The two angle adjustment parts 3 are arranged symmetrically.

[0035] Example 2

[0036] The difference between this embodiment and Embodiment 1 is that the example in this embodiment optimizes the specific structure of the angle adjustment part 3, such as figure 2 As shown, the specific settings are as follows:

[0037] The top end of the push-pull shaft of the push cylinder 31 is sleeved on the moving rod 33 ; the top end of the moving rod 33 is also provided with a...

Embodiment 4

[0039] The difference between this embodiment and Embodiment 3 is that the specific structure of the pressing device is optimized in this embodiment, and the specific settings are as follows:

[0040] The pressing device includes a vertical bar 6 whose bottom end is fixed on the operation table body 1, a chute 7 arranged on the vertical bar 6, and a connecting rod 8 which is arranged in the chute 7 and is used to move along the chute 7 at one end. , the compression block 5 fixed on the other end of the connecting rod 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com