Bottle cap stamping pre-screwing locating mechanism

A positioning mechanism and bottle cap technology, which is applied to screw caps and other directions, can solve the problems of unqualified products, high solution cost, and inability to complete the capping operation normally, and achieve the effect of improving the qualification rate and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

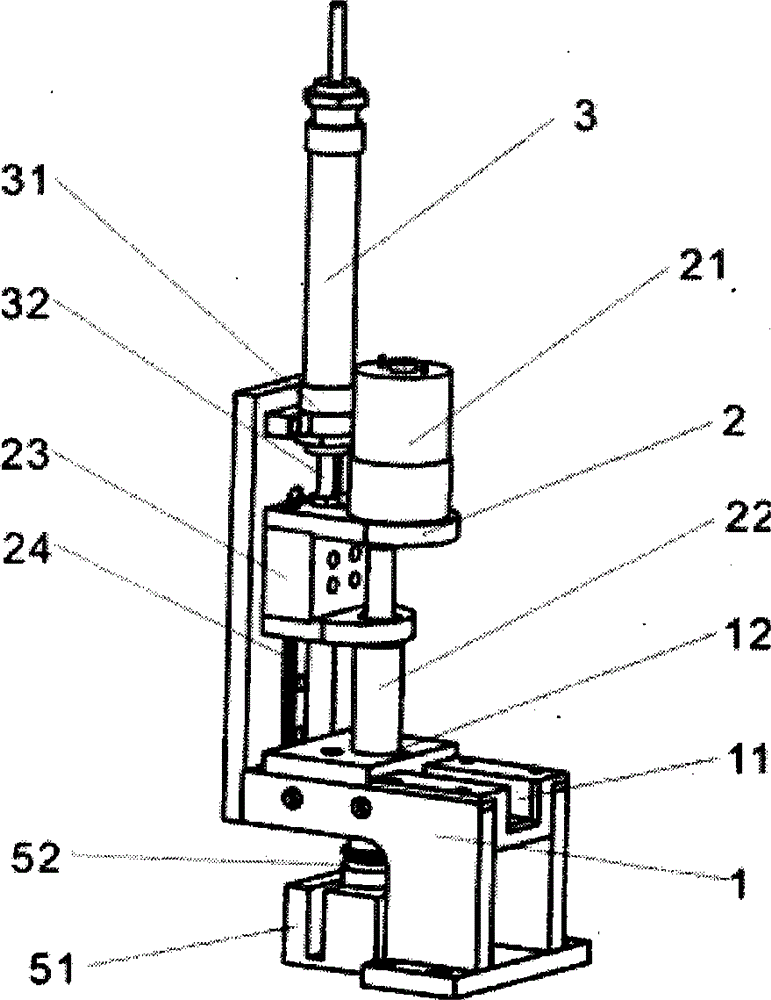

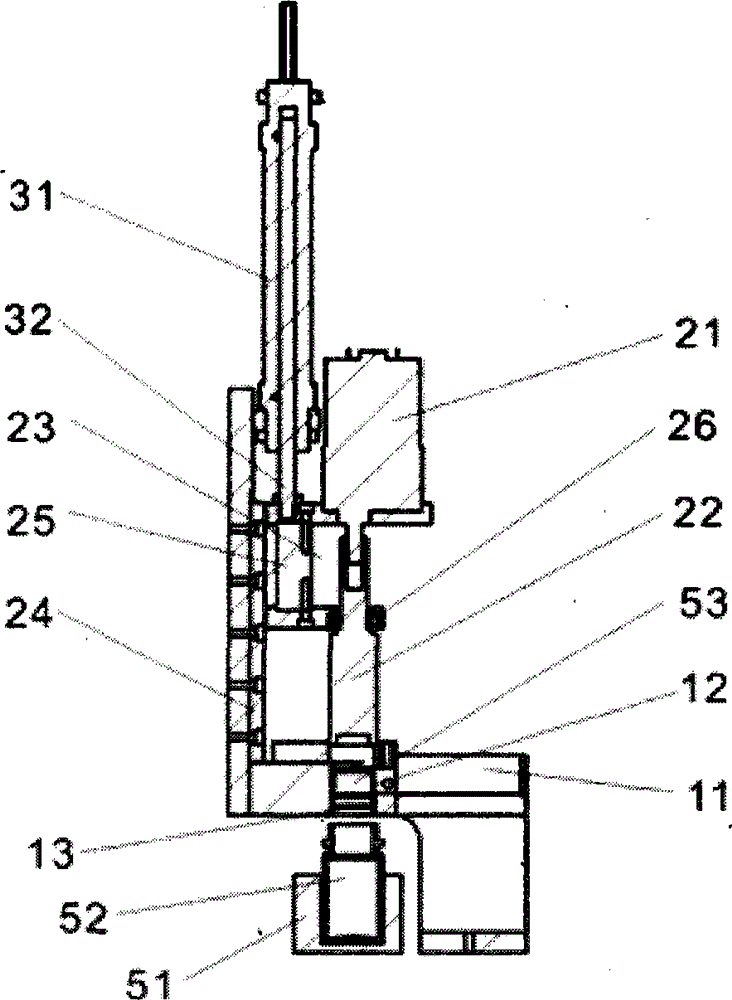

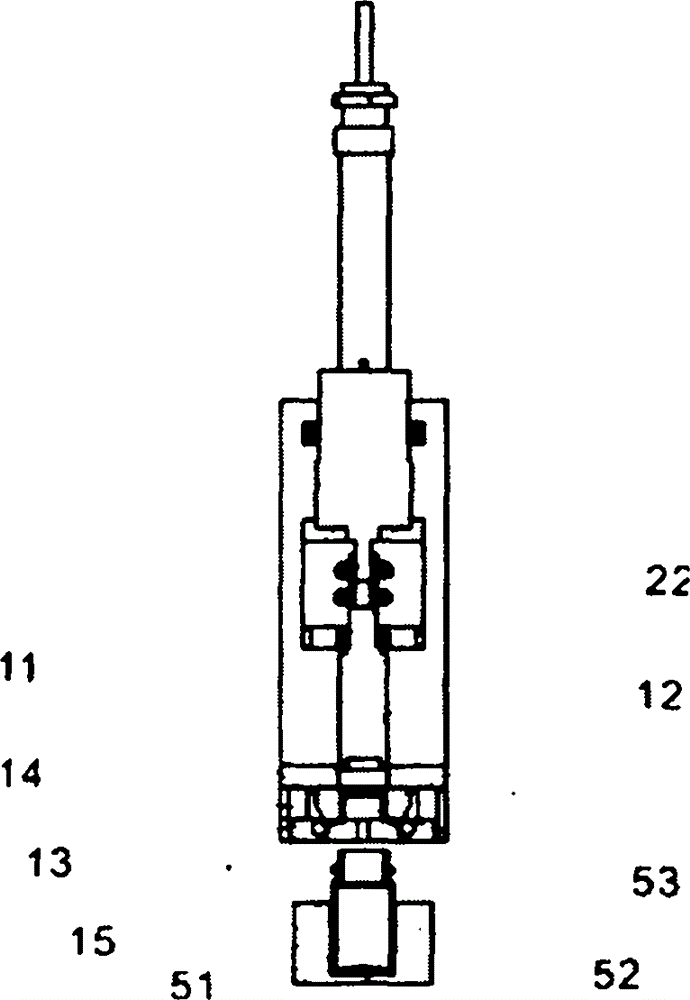

[0024] Refer below Figure 1~3 A bottle cap stamping pre-rotation positioning mechanism according to an embodiment of the present invention is described.

[0025] Such as figure 1 , figure 2 As shown, a bottle cap stamping pre-rotation positioning mechanism is composed of a bottle cap positioning block 1, a pre-rotation capping assembly 2, a capping power assembly 3 and a bottle positioning block 51. The bottle cap positioning block 1 includes a bottle cap flow inlet 11 , bottle cap positioning through hole 12, support cover block 13, support cover block groove 14 (not shown in the figure) and pin shaft 15 (not shown in the figure), pre-spin punching cap assembly 2 includes pre-spin motor 21, bottle Cap stamping head 22, pre-rotating cap frame 23, linear slide rail 24, linear slider 25, and bearing 26, cap punching power assembly 3 includes cylinder block 31 and cylinder push rod 32.

[0026] The rotating shaft of the pre-spinning motor 21 is fixed vertically downward on t...

Embodiment 2

[0032] Embodiment 2 mainly improves the linear motion output power assembly 3 in embodiment 1, which is improved in the form of a cylinder to realize the output of linear motion with a motor rocker mechanism.

[0033] In this example, if Figure 4 As shown, the capping power assembly 3 is a motor rocker mechanism that provides reciprocating linear motion power, including a geared motor 41, a driving rocker 42, a transmission rocker 43, a rocker fixing block 44, an optical fiber sensor 45, a sensor block 46, Spring 47 and long screw 48.

[0034] The whole motor rocker mechanism is arranged on the top of the pre-rotation punching cap assembly 2, and the reduction motor 41 is fixed on the upper outer side of the bottle cap positioning block 1, and the rotating shaft of the reduction motor 41 extends to the inside of the bottle cap positioning block 1 through the through hole of the bottle cap positioning block 1, The length of the transmission rocker 43 is greater than twice the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com