Distributing adjusting mechanism for heat treatment furnace

A heat treatment furnace, split flow adjustment technology, applied in the field of heat treatment furnace split flow adjustment mechanism, can solve the problems of not being able to ensure metal objects, affecting heat treatment effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

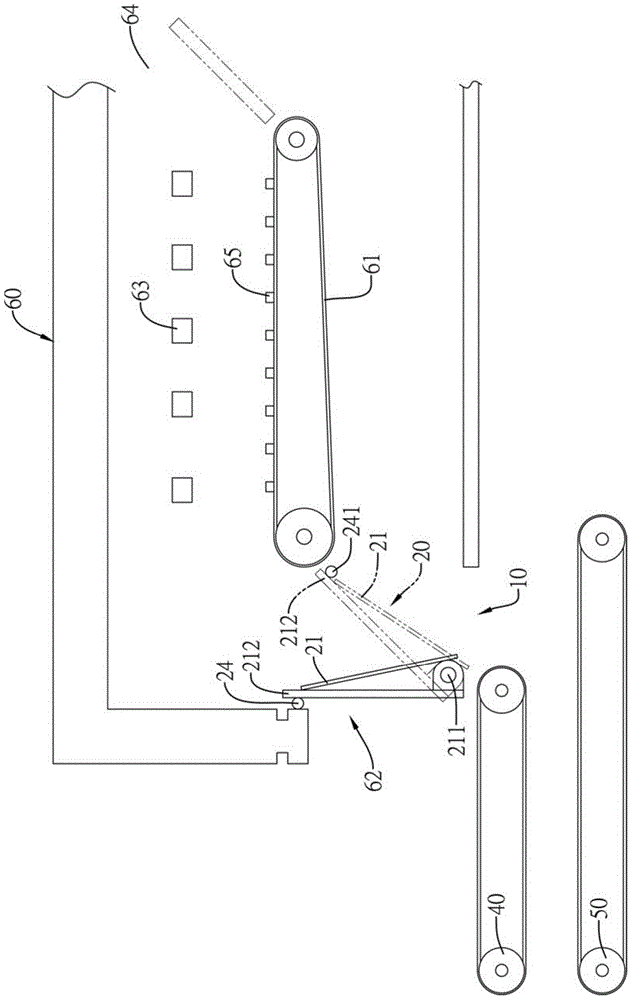

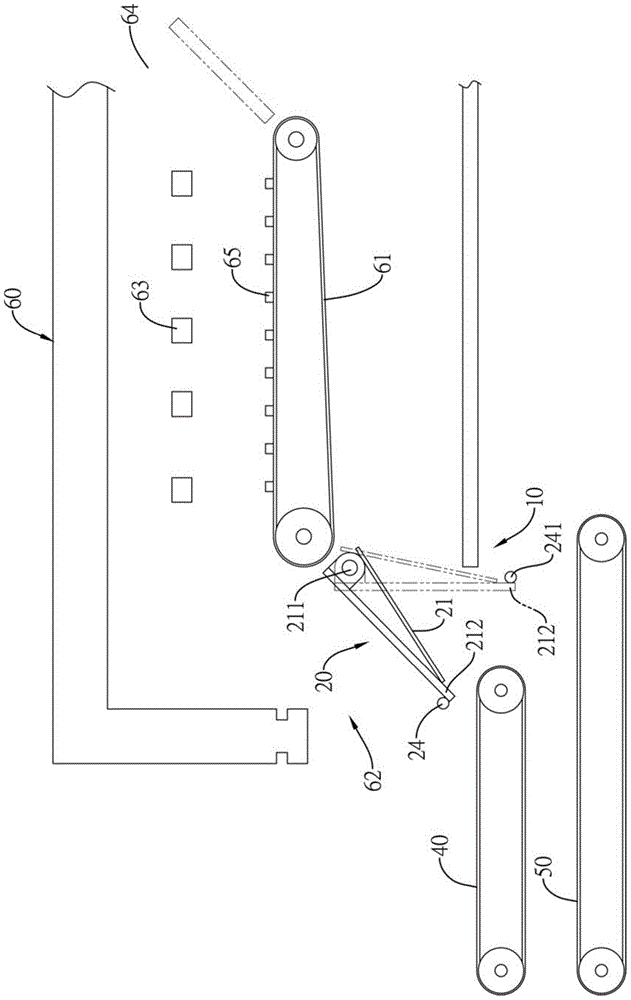

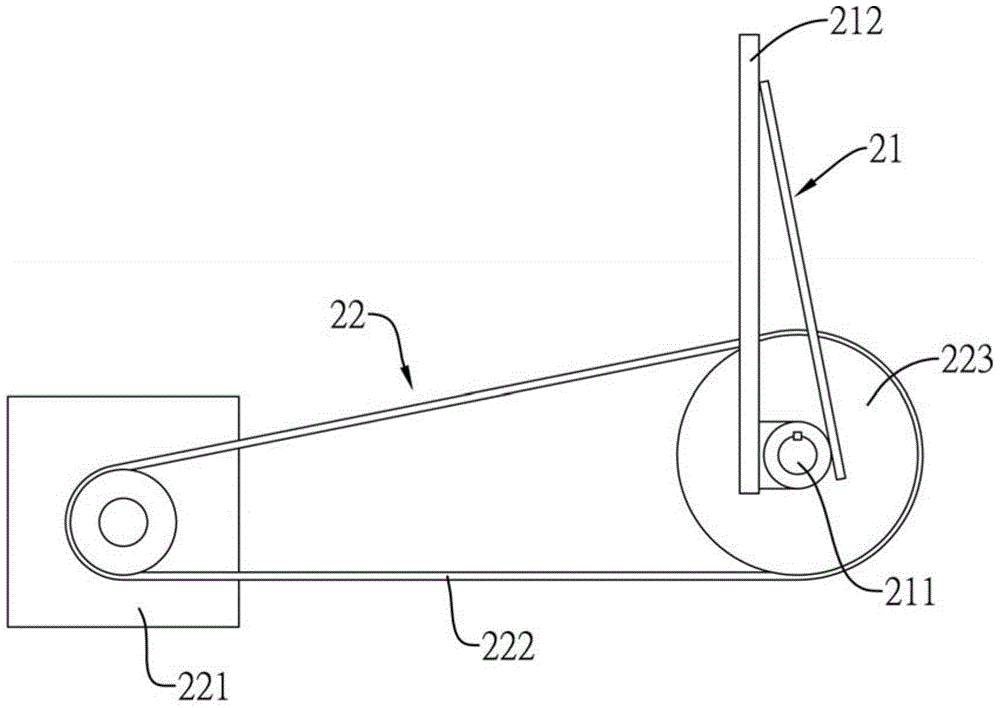

[0050] The diversion adjustment mechanism of the present invention mainly includes a diversion device and a plurality of collection devices, wherein the diversion device is arranged between the conveyor belt inside the heat treatment furnace and the discharge port, and the plurality of collection devices are arranged at the discharge of the heat treatment furnace At the outlet, the objects that have completed the heat treatment process in the heat treatment furnace are diverted to a specific collection device through a diversion device, and the above-mentioned technical features can have various implementation forms, wherein the diversion device can be further a rotary diversion device, or It is a translational diversion device. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com