Patents

Literature

34results about How to "To achieve the purpose of diversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

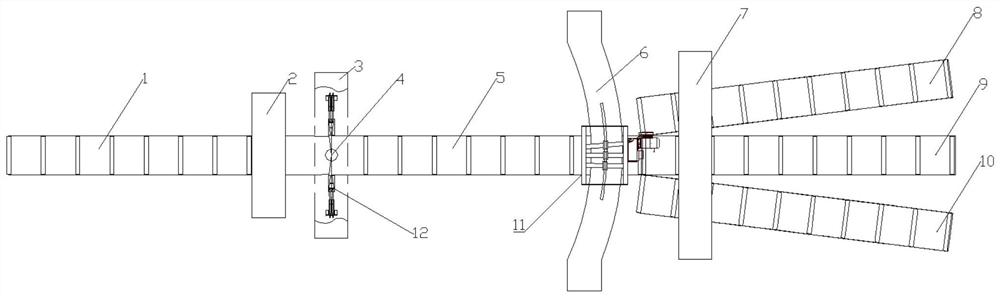

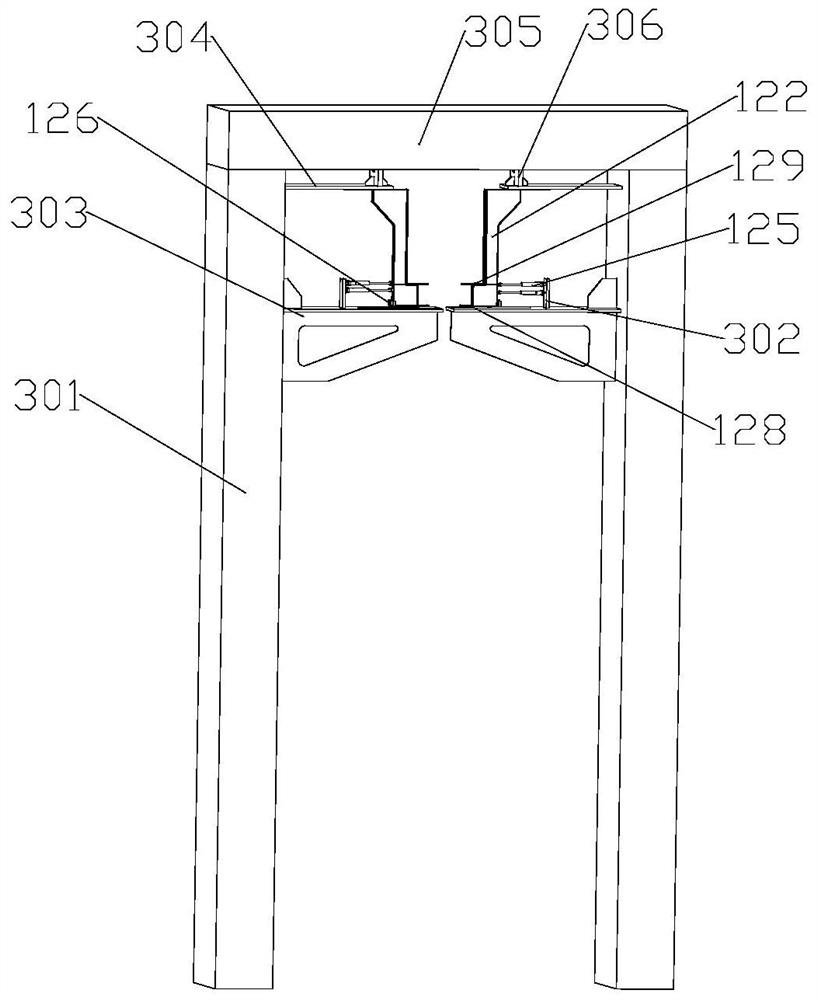

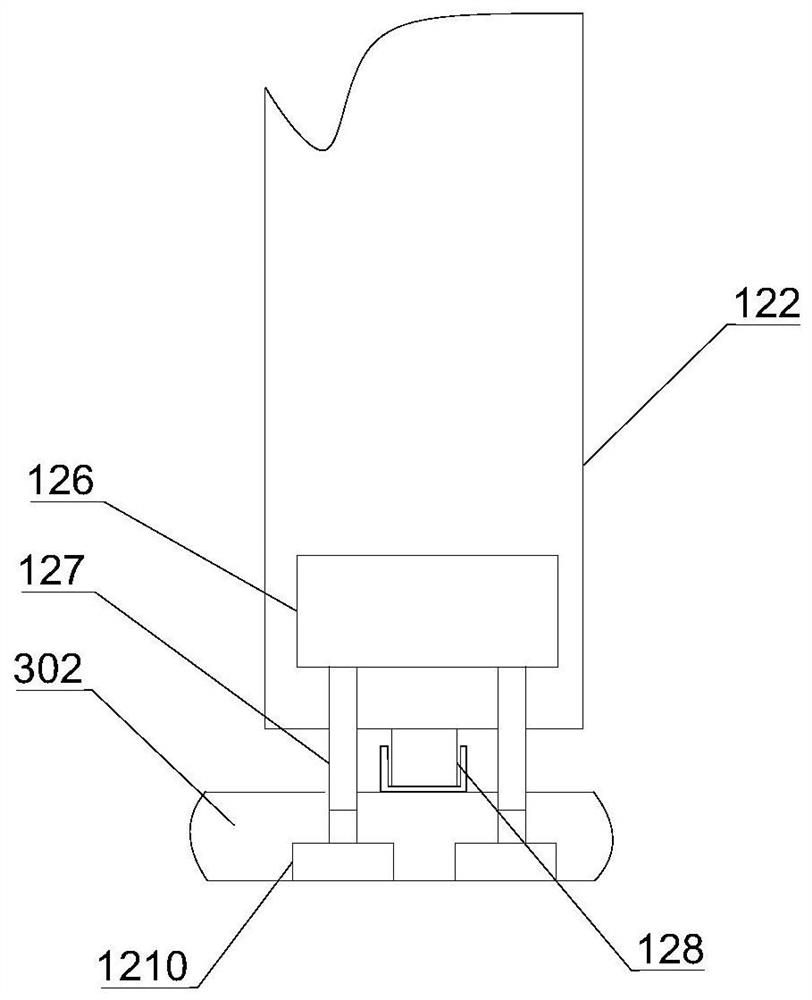

Rail transit turnout system

ActiveCN112127217ATo achieve the purpose of diversionReduce quality problemsRailway tracksStructural engineeringControl theory

The invention relates to a rail transit turnout system. A first end of a turnout beam of the system is arranged on a first transition pier column, the first end of the turnout beam is rotatably connected with the first transition pier column through a center pin, the center pin is arranged in the vertical direction, a second end of the turnout beam is arranged on a second transition pier column, and the second end of the turnout beam can travel on the second transition pier column; the number of branch line rail beams is at least two, the branch line rail beams are fixedly supported through aplurality of branch line pier studs arranged at intervals, each branch line rail beam is provided with a first end and a second end which are opposite, the turnout beam is arranged between the foundation rail beam and the branch line rail beams, and the first end of the turnout beam is in butt joint with the end, facing the turnout beam, of the foundation rail beam; the second end of the turnout beam is operably and selectively in butt joint with the first end of a certain branch rail beam, and the second end of each branch rail beam extends in the direction away from the turnout beam. The system is simple and reliable to operate, can effectively shorten the switch time and improve the transportation efficiency, and has a very good practical value.

Owner:CRRC YANGTZE CO LTD

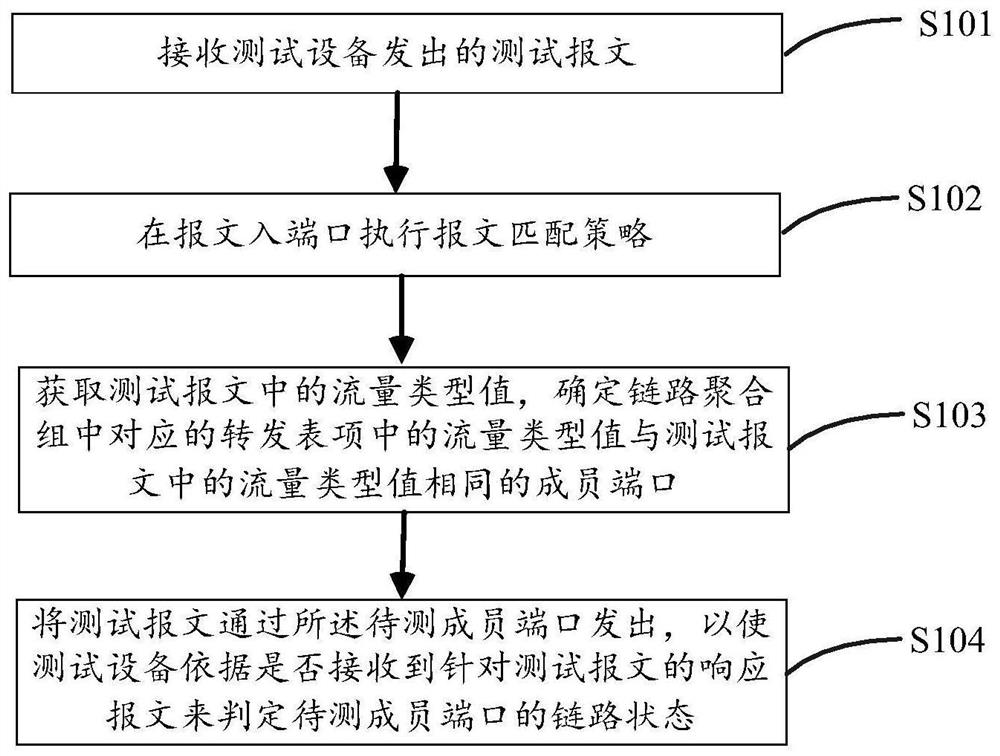

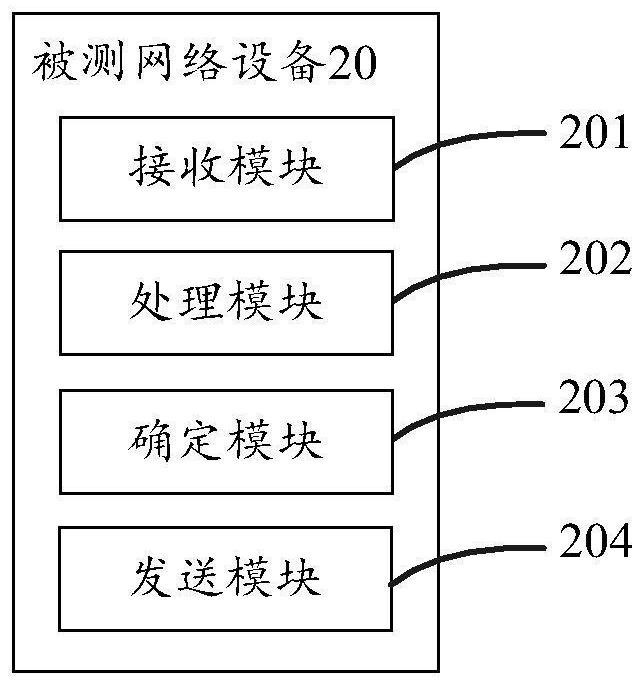

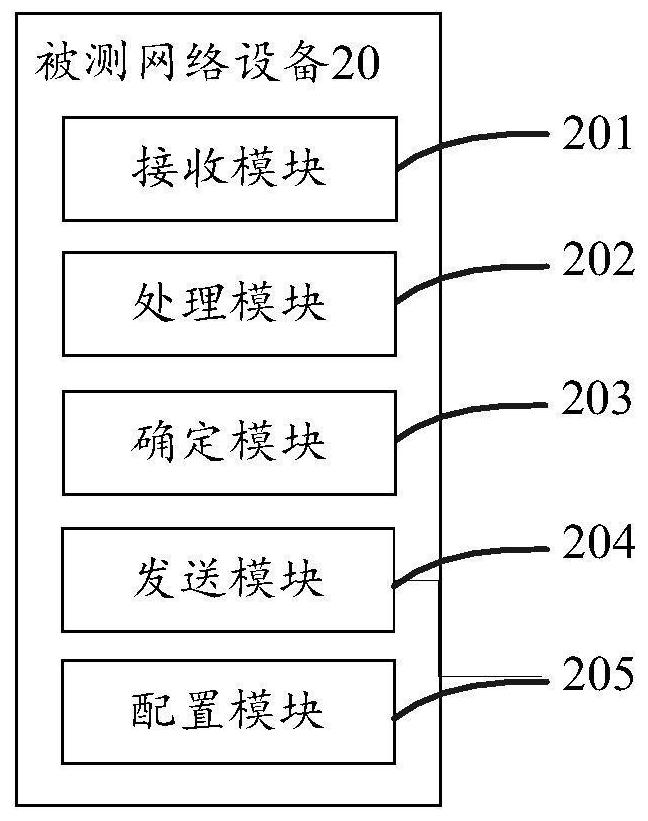

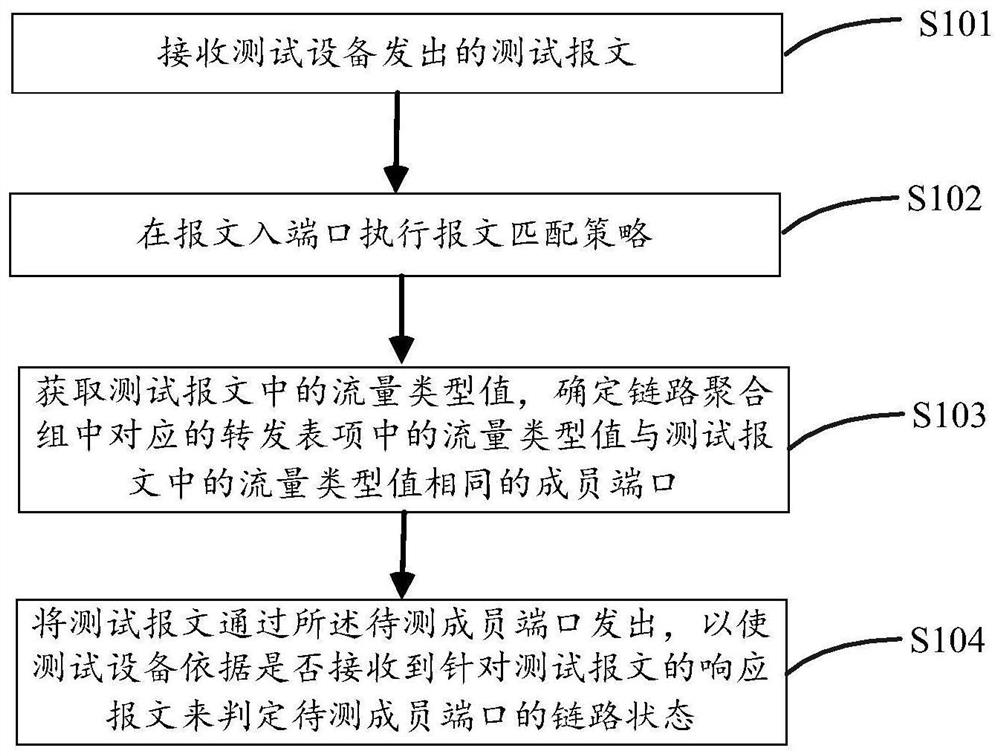

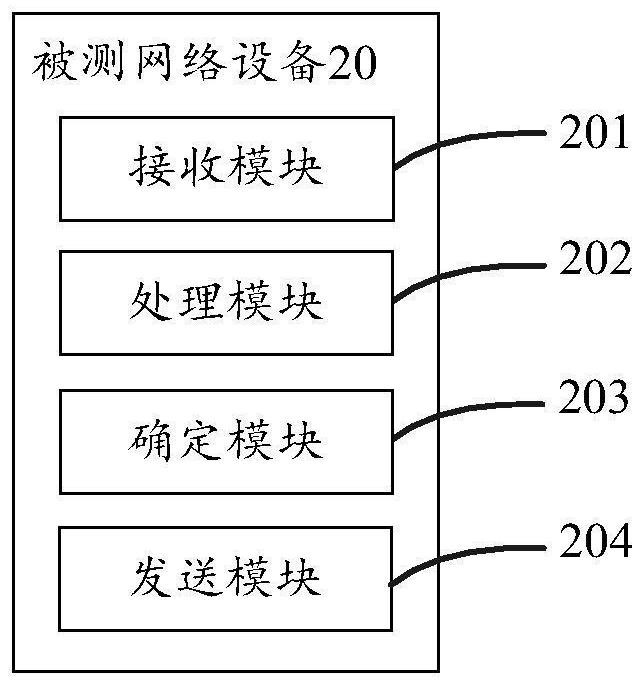

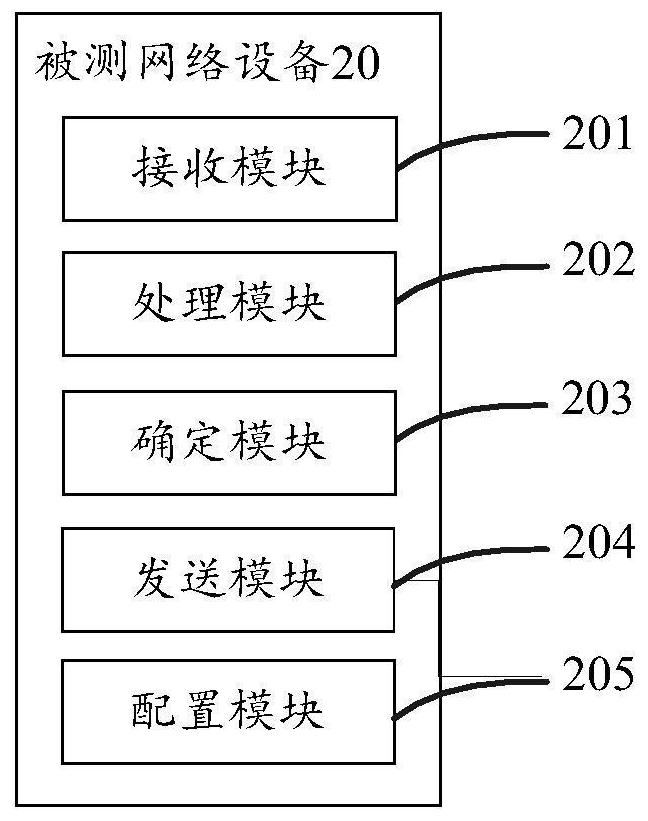

Port link state detection method, device and system

ActiveCN111682989ATo achieve the purpose of diversionData switching networksEngineeringComputer network

The embodiment of the invention discloses a port link state detection method, device and system, relates to the field of data communication, and realizes that a user can perceive the link state of each member port in a link aggregation group. The method comprises the following steps: receiving a test message sent by test equipment, and executing a message matching strategy at a message inlet port;obtaining a flow type value in the test message, and determining a member port of which the flow type value in a corresponding forwarding entry in a link aggregation group is the same as the flow type value in the test message, the determined member port being a member port to be tested; and sending the test message through the to-be-tested member port, so that the test equipment judges the linkstate of the to-be-tested member port according to whether a response message for the test message is received or not.

Owner:MAIPU COMM TECH CO LTD

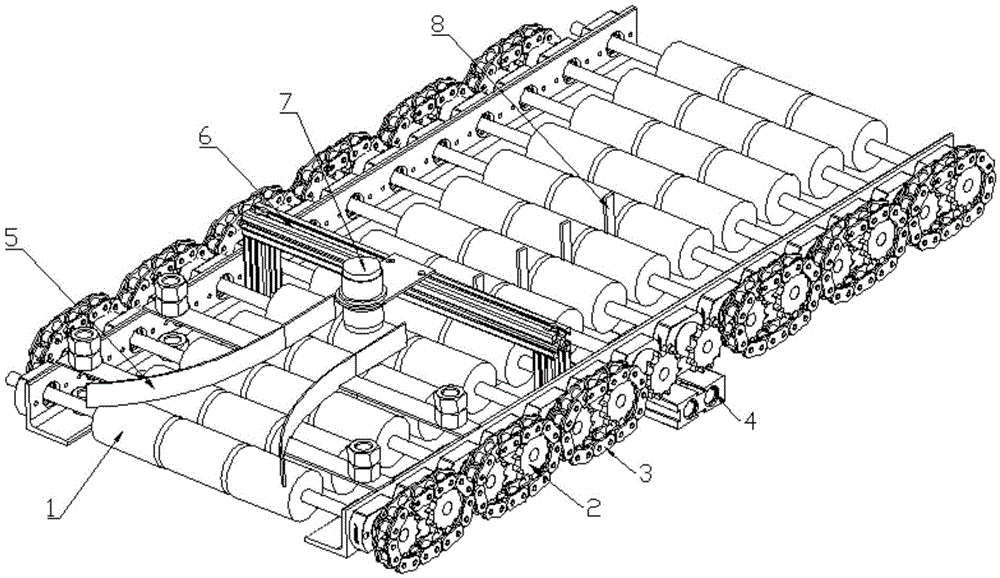

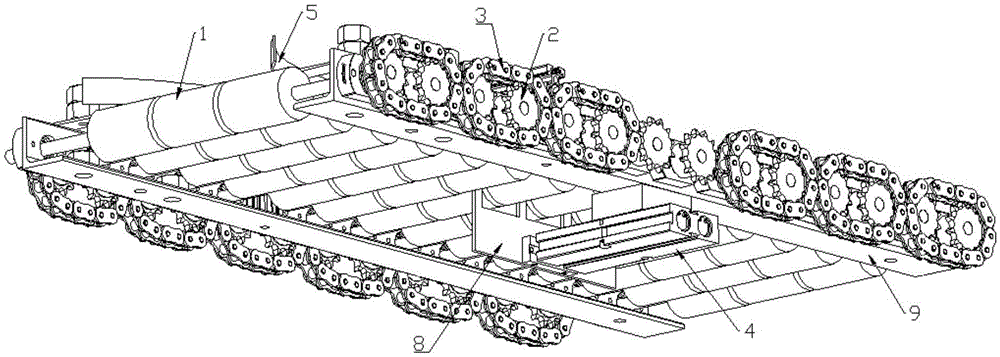

Washing flow divider

InactiveCN105460485ATo achieve the purpose of diversionReduce manufacturing costConveyorsRoller-waysAcute angleEngineering

The invention provides a washing flow divider. The washing flow divider comprises a transmission mechanism and a flow dividing mechanism, wherein the transmission mechanism comprises a conveying assembly and a power assembly, the conveying assembly comprises a plurality of conveying rollers, the plurality of conveying rollers are arranged in parallel, the power assembly provides the conveying rollers with power rotating around respective axes, and the rotation of the plurality of conveying rollers in the same direction forms the conveying trajectory of the conveying assembly; and the flow dividing mechanism comprises a pushing power component, a shifting fork and a flow dividing guide vane positioned above the conveying rollers, the flow dividing guide vane is an arc-shaped sheet and is positioned at the tail of the conveying trajectory of the conveying assembly, the included angle between the tangent line of the flow dividing guide vane and the conveying trajectory of the conveying assembly is an acute angle, and the flow dividing guide vane is bent towards the side edge of the conveying trajectory. According to the invention, the purpose of dividing flow is achieved through the cooperation arrangement of the transmission mechanism and the flow dividing mechanism; and at the same time, as the flow dividing guide vane is used as the component for realizing flow dividing, the technology can reduce production cost. The washing flow divider is applied to the production of various products.

Owner:TIANJIN TTX GROUP

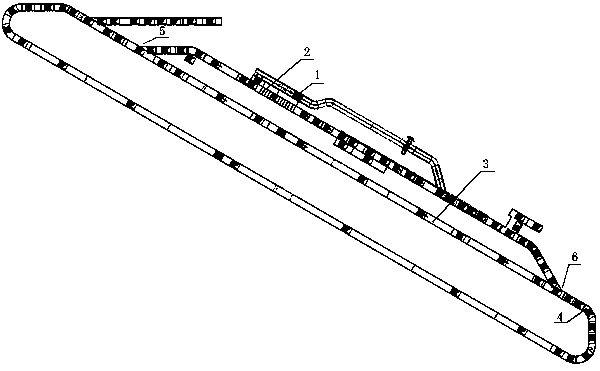

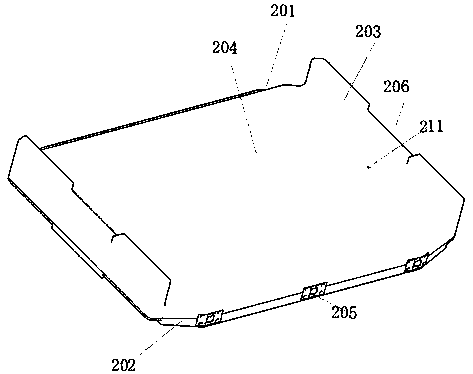

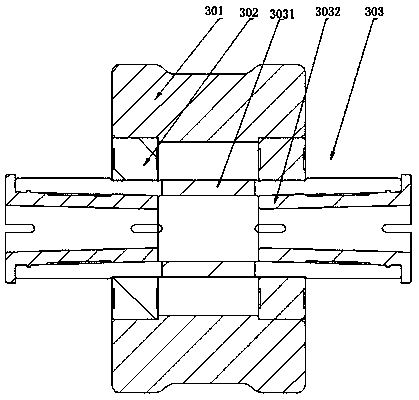

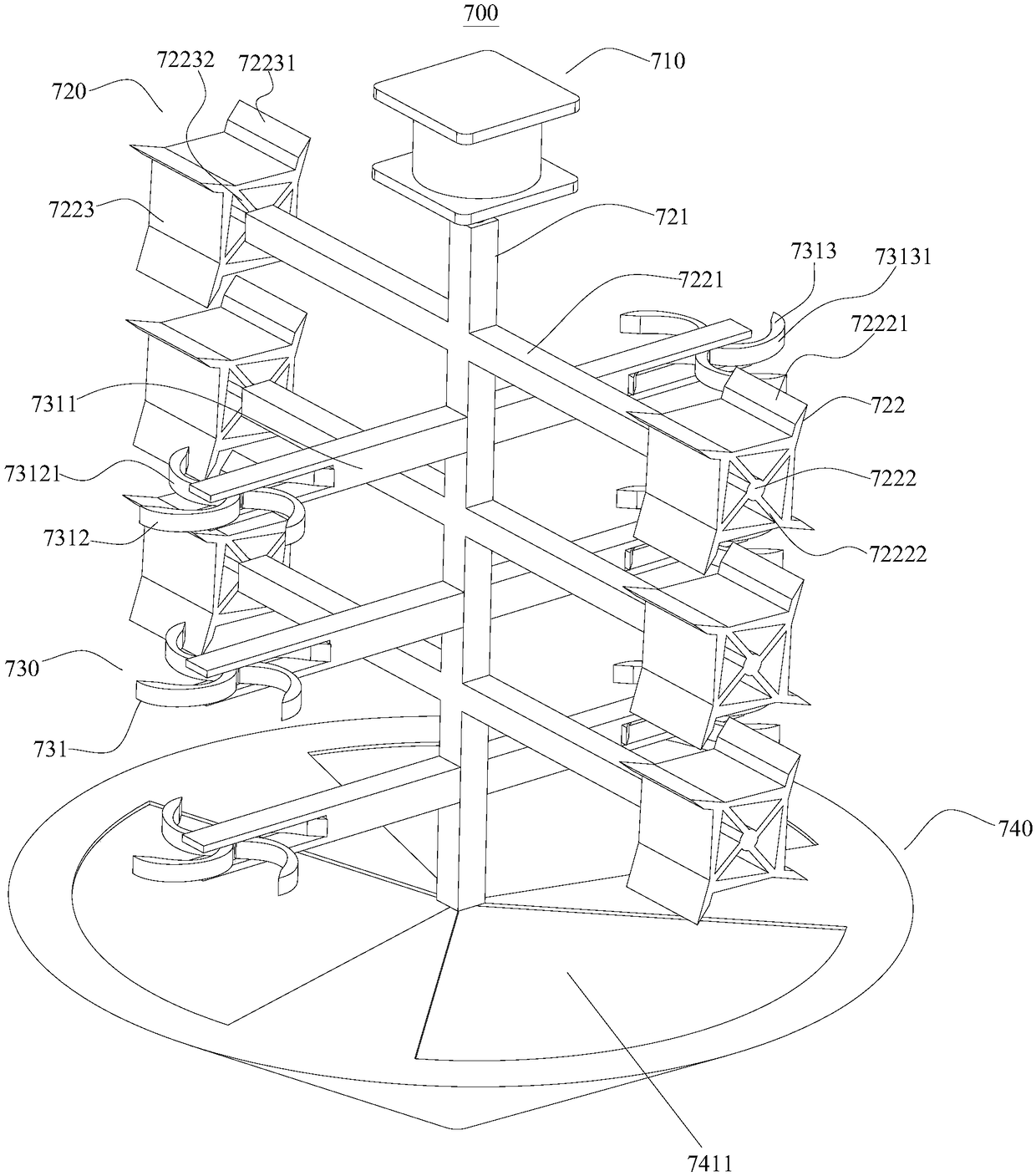

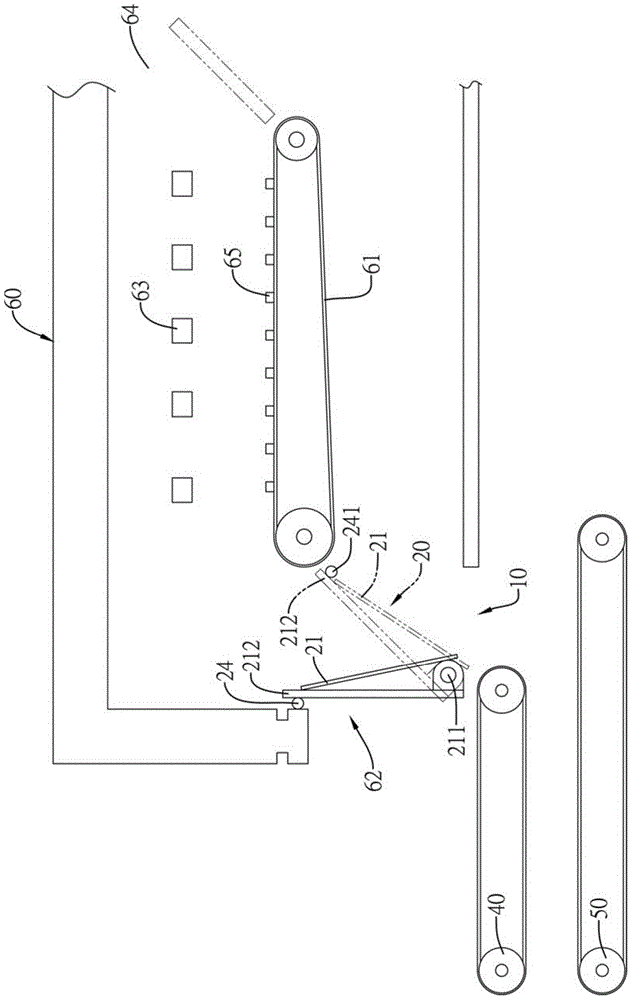

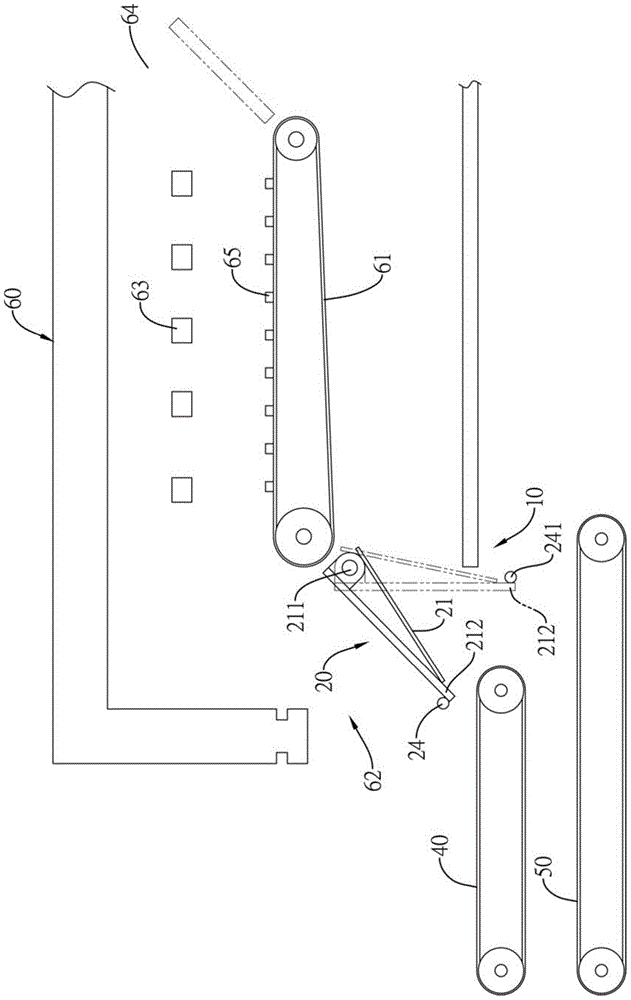

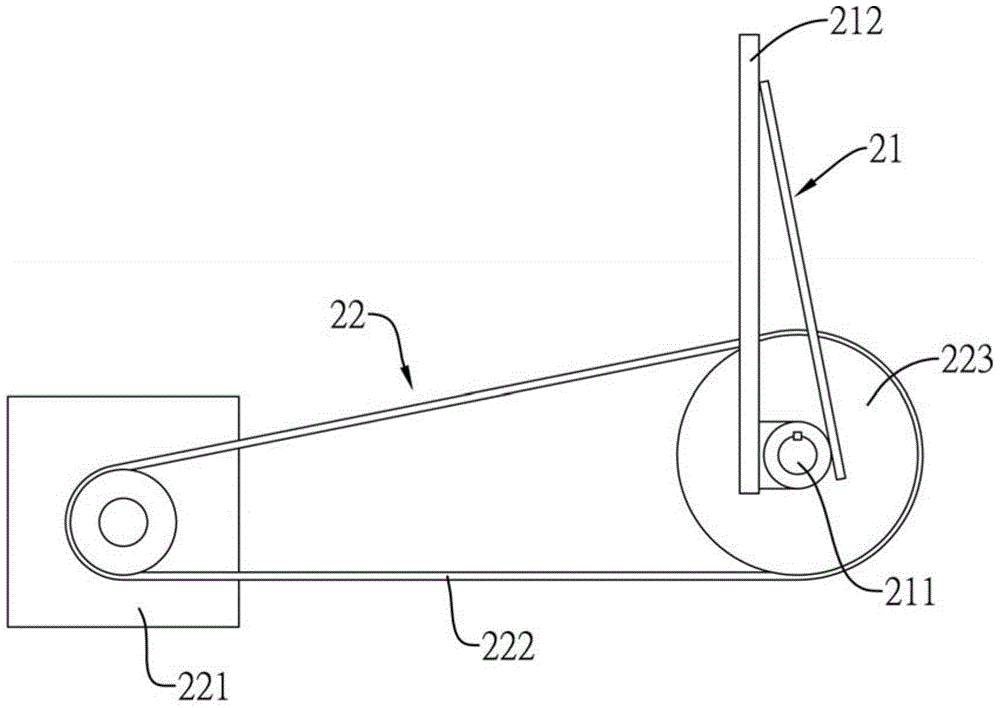

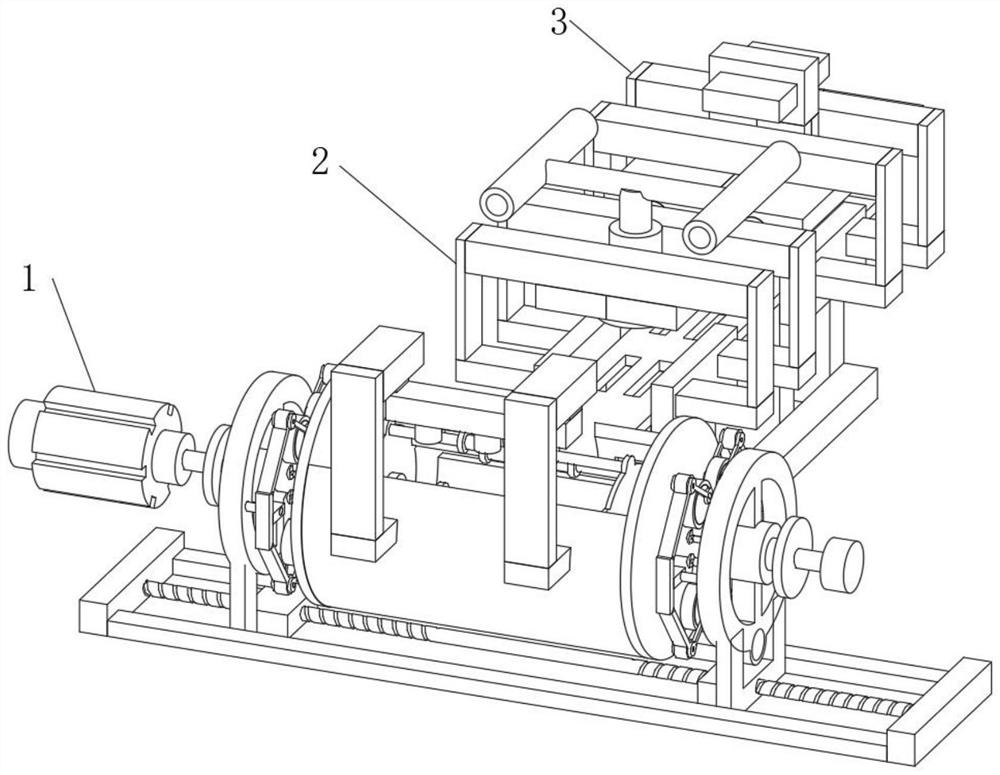

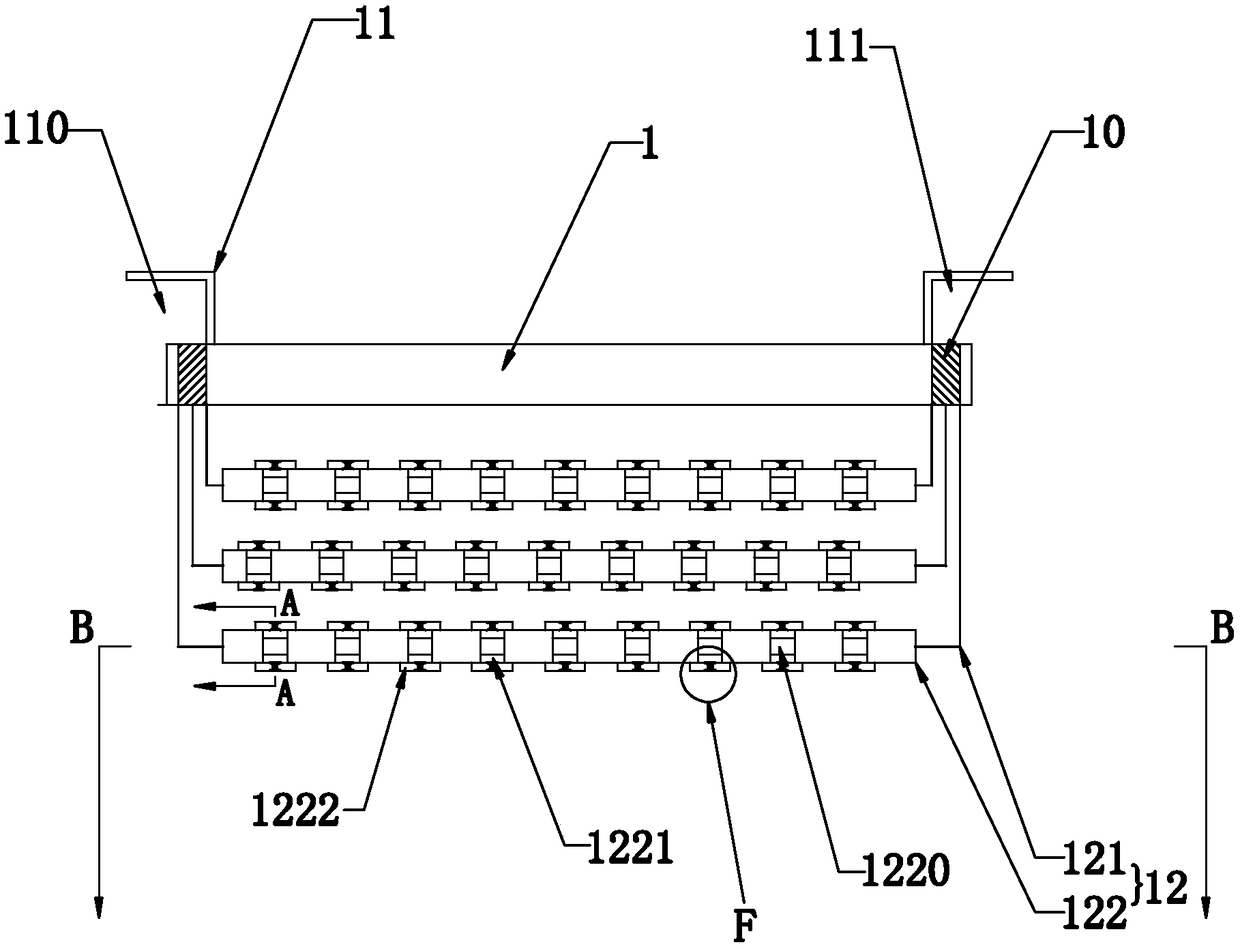

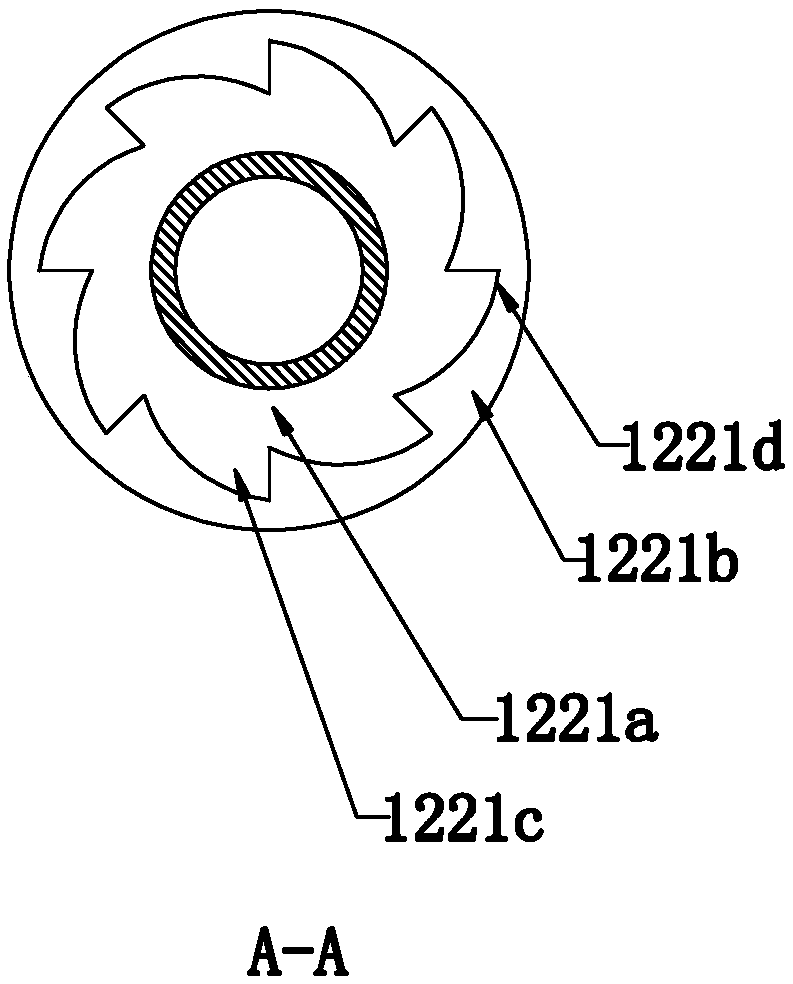

Airport luggage high-speed conveying and sorting system

ActiveCN109160251AImprove stabilityEnsure safetyConveyor partsMechanical conveyorsLogistics managementEngineering

The invention belongs to the civil aviation logistics application field, and particularly relates to an airport luggage high-speed conveying and sorting system. The system comprises a track part, a dynamic sorting device and a luggage high-speed conveying tray; the luggage high-speed conveying tray is used for conveying the luggage on the track part, and the dynamic sorting device is used for carrying out high-speed sorting on the luggage; the track part comprises a straight track, a turning conveyor, at least one section of rapid shunting conveying device and at least one section of rapid confluence conveying device; and a supporting wheel device capable of realizing rapid dismounting and mounting is arranged on the track part. According to the system, high-speed conveying and sorting ofthe airport luggage can be realized; and the whole system is rearranged, a conveying part and a luggage sorting part in the system are mainly improved, so that the speed of conveying the luggage of the whole system can be up to 10 m / s, the stability of the luggage sorting part in the system during tipping is improved, so that the safety and stability when the luggage is conveyed and tipped can beguaranteed on the premise that the system guarantees that the luggage can be conveyed at a high speed.

Owner:CIVIL AVIATION LOGISTICS TECH

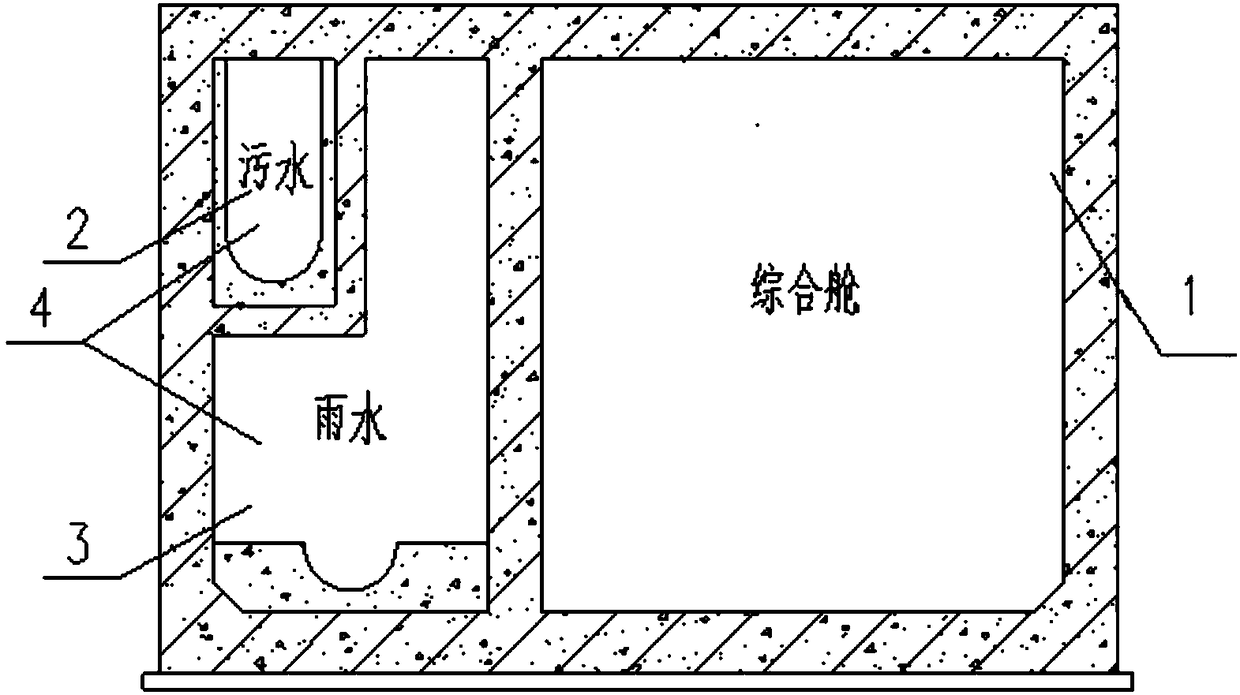

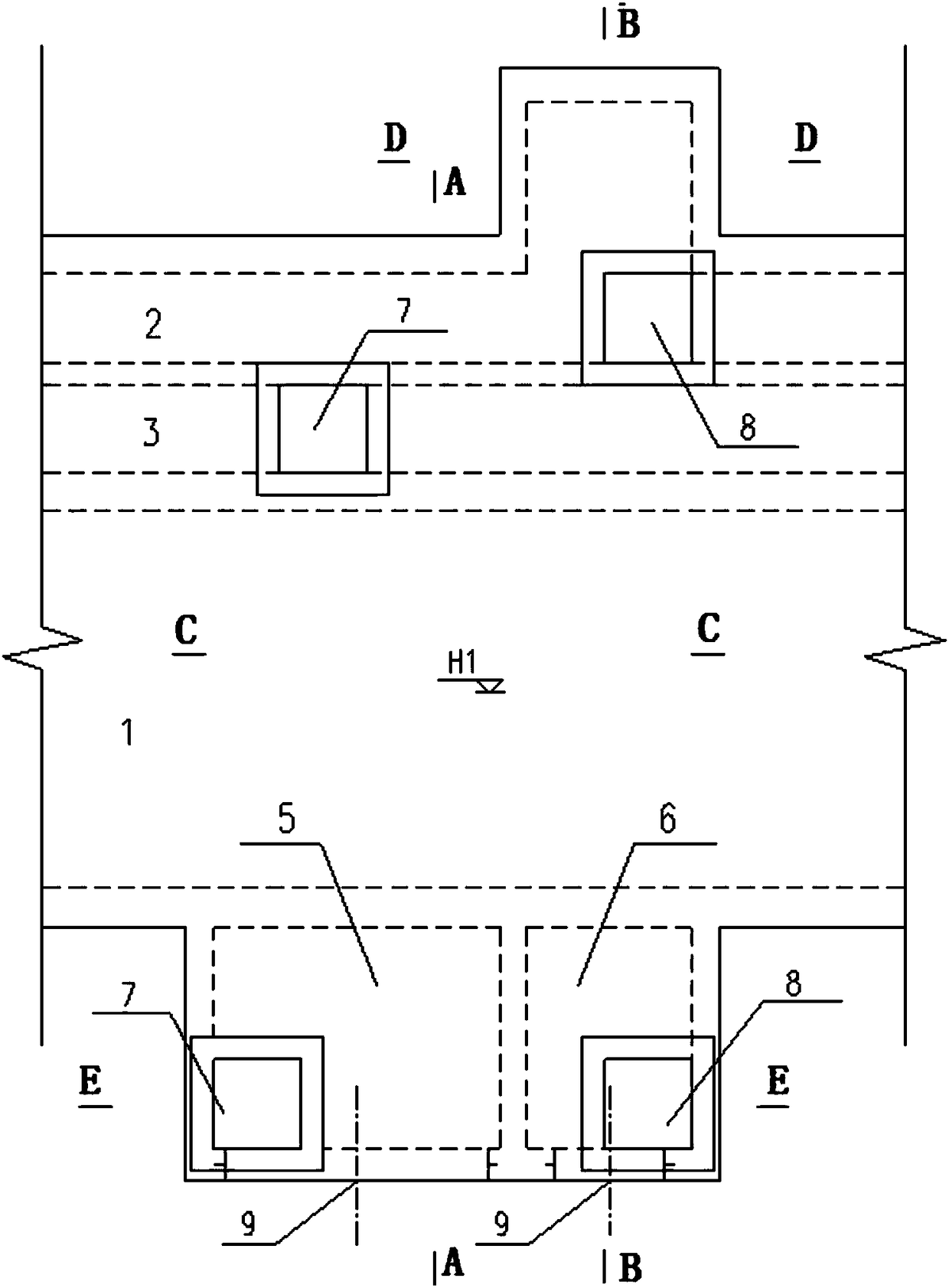

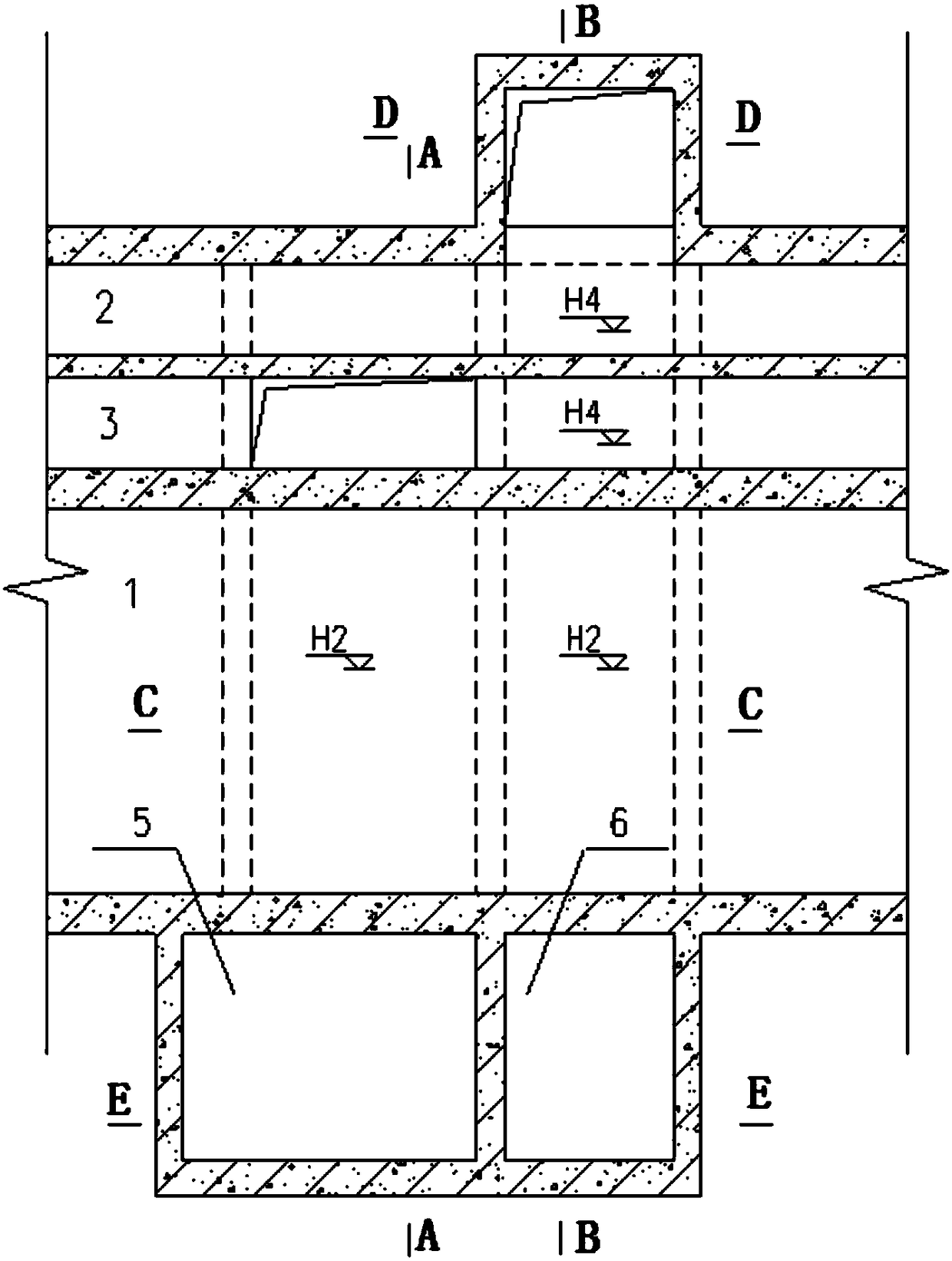

Flow-dividing transferring opening for utility tunnel drainage cabin

PendingCN108468349AEasy maintenanceMeet drainage needsArtificial islandsSewerage structuresWall plateEngineering

The invention discloses a flow-dividing transferring opening for a utility tunnel drainage cabin. The flow-dividing transferring opening comprises a rainwater and sewage passing tank culvert which isarranged on the lower portion of the standard section of a utility tunnel; the rainwater and sewage passing tank culvert comprises a rainwater passing tank culvert body communicating with a rainwatertank culvert cabin, and a sewage passing tank culvert body communicating with a sewage tank culvert cabin; drainage through-wall casing pipes are pre-embedded on wall plates at the ends of the rainwater passing tank culvert body and the sewage passing tank culvert body, and thus the rainwater passing tank culvert body and the sewage passing tank culvert body can be connected to a municipal drainage system in the direction perpendicular to the way side of the utility tunnel through a pipeline. According to the flow-dividing transferring opening for the utility tunnel drainage cabin, the problems that a traditional drainage piping enters the utility tunnel, the drainage lower points are located on the side close to an integrated cabin, rainwater and sewage cannot cross the tunnel integratedcabin to be drained in the process, consequently, the drainage pressure at the tail end is excessively large are solved; and by combining the arrangement of a corresponding rainwater inspection well and a sewage inspection well, the drainage requirements of land blocks on the two sides of a road are met, and meanwhile, overhauling is convenient.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

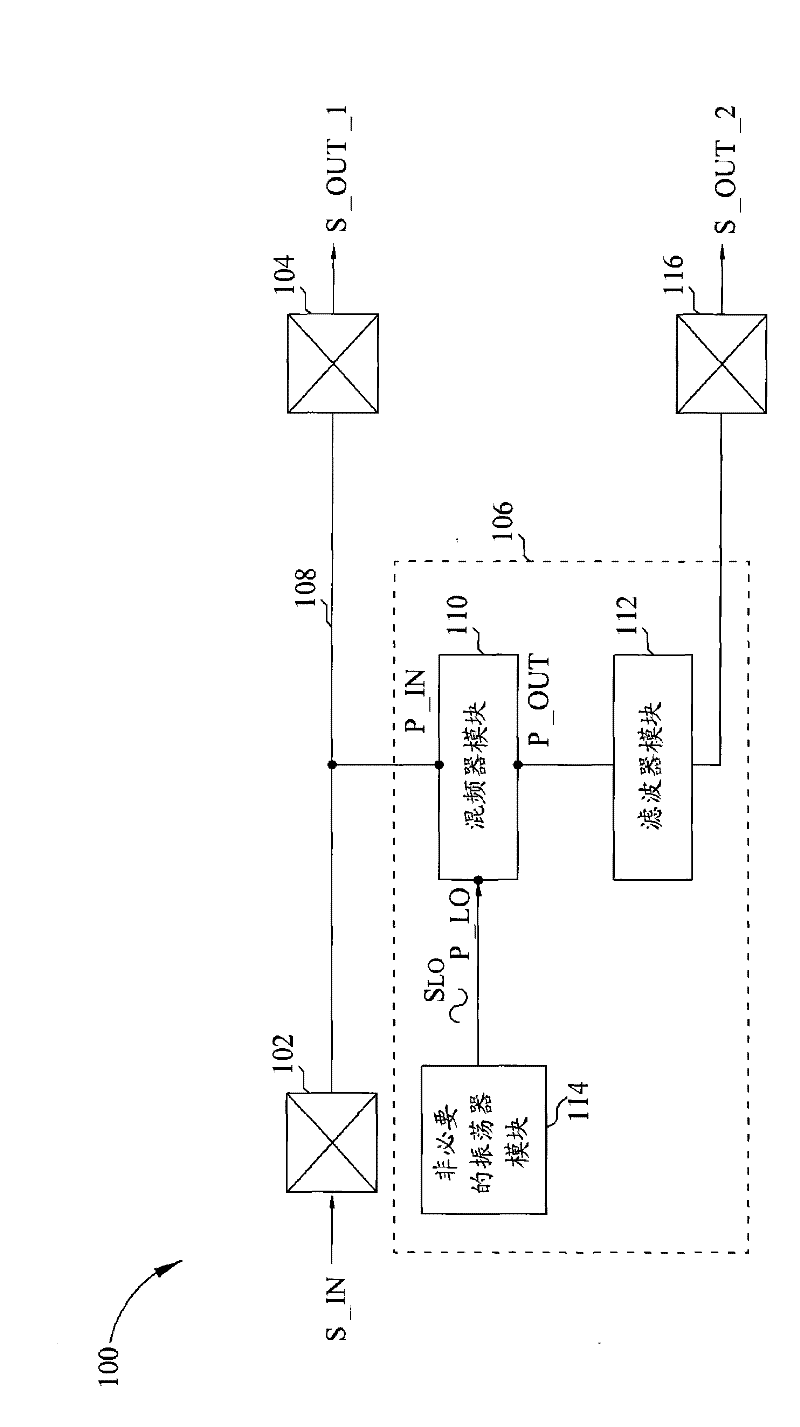

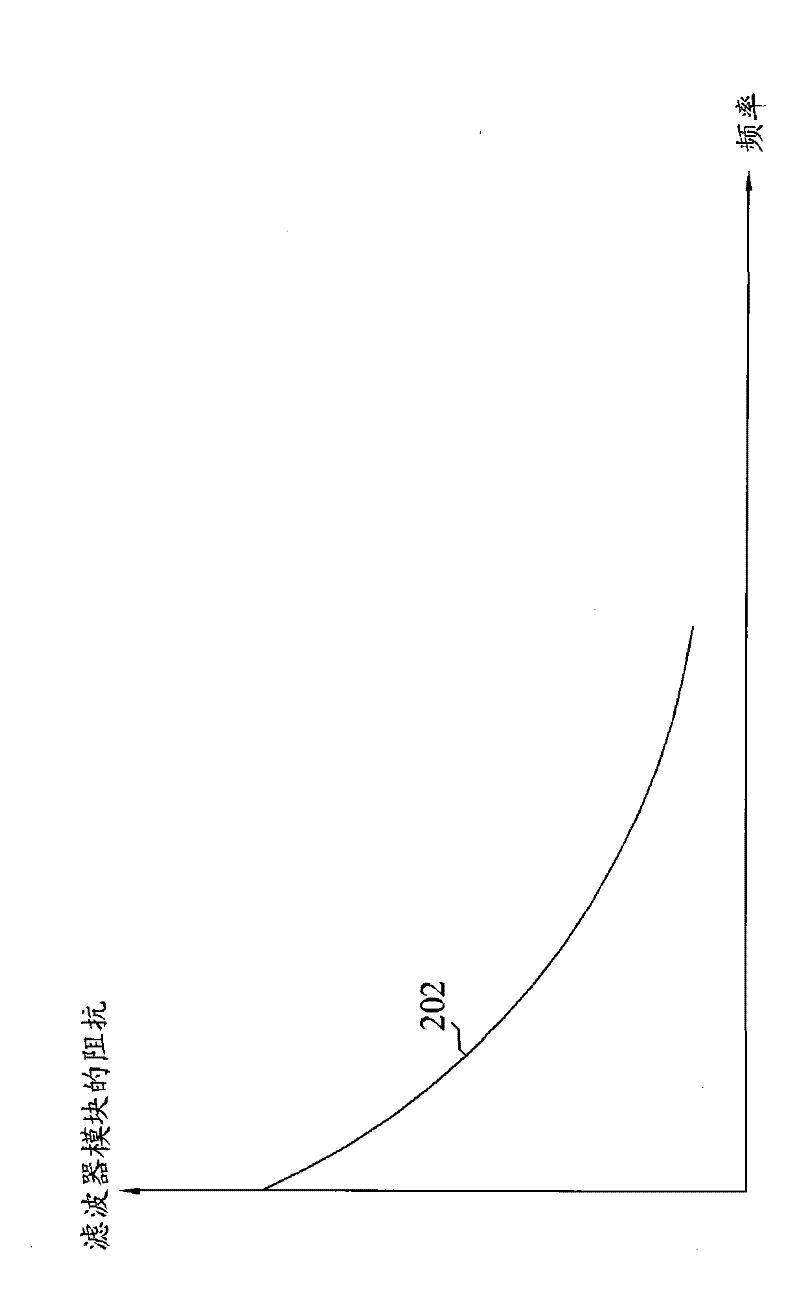

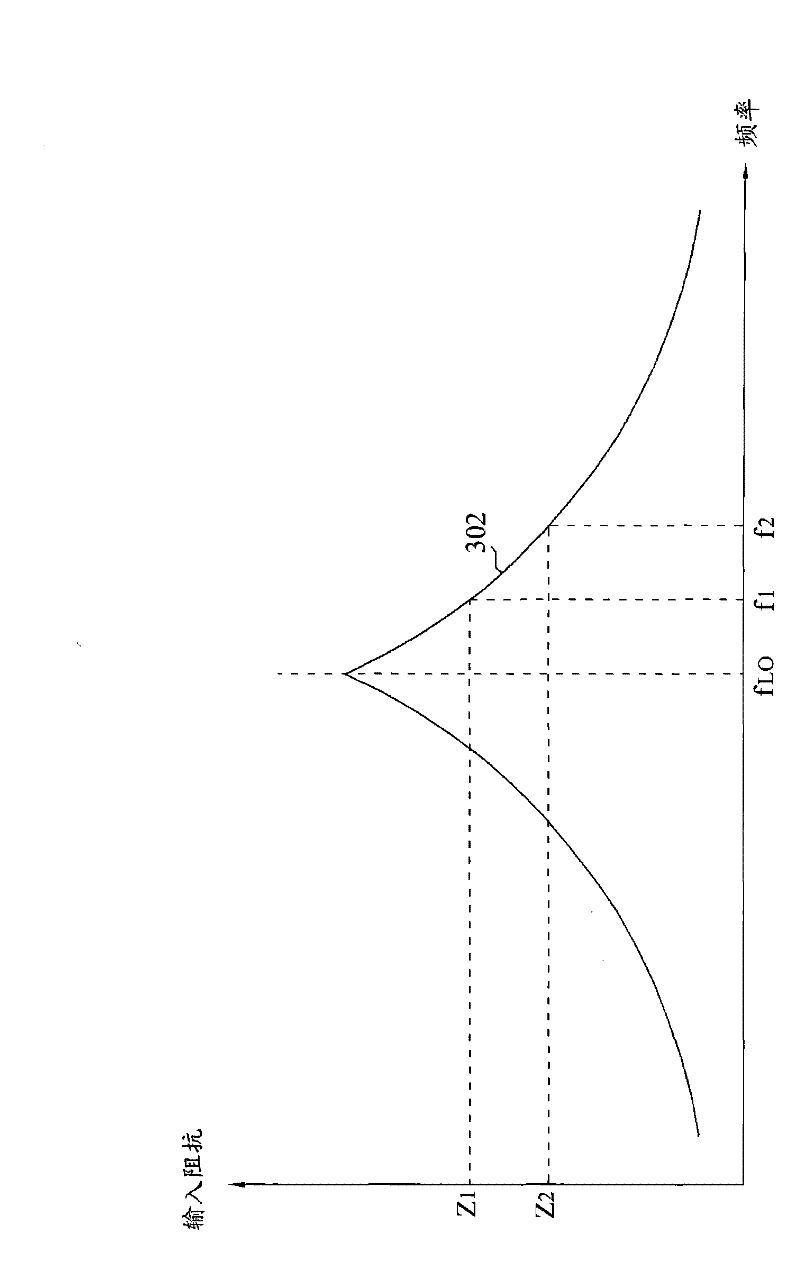

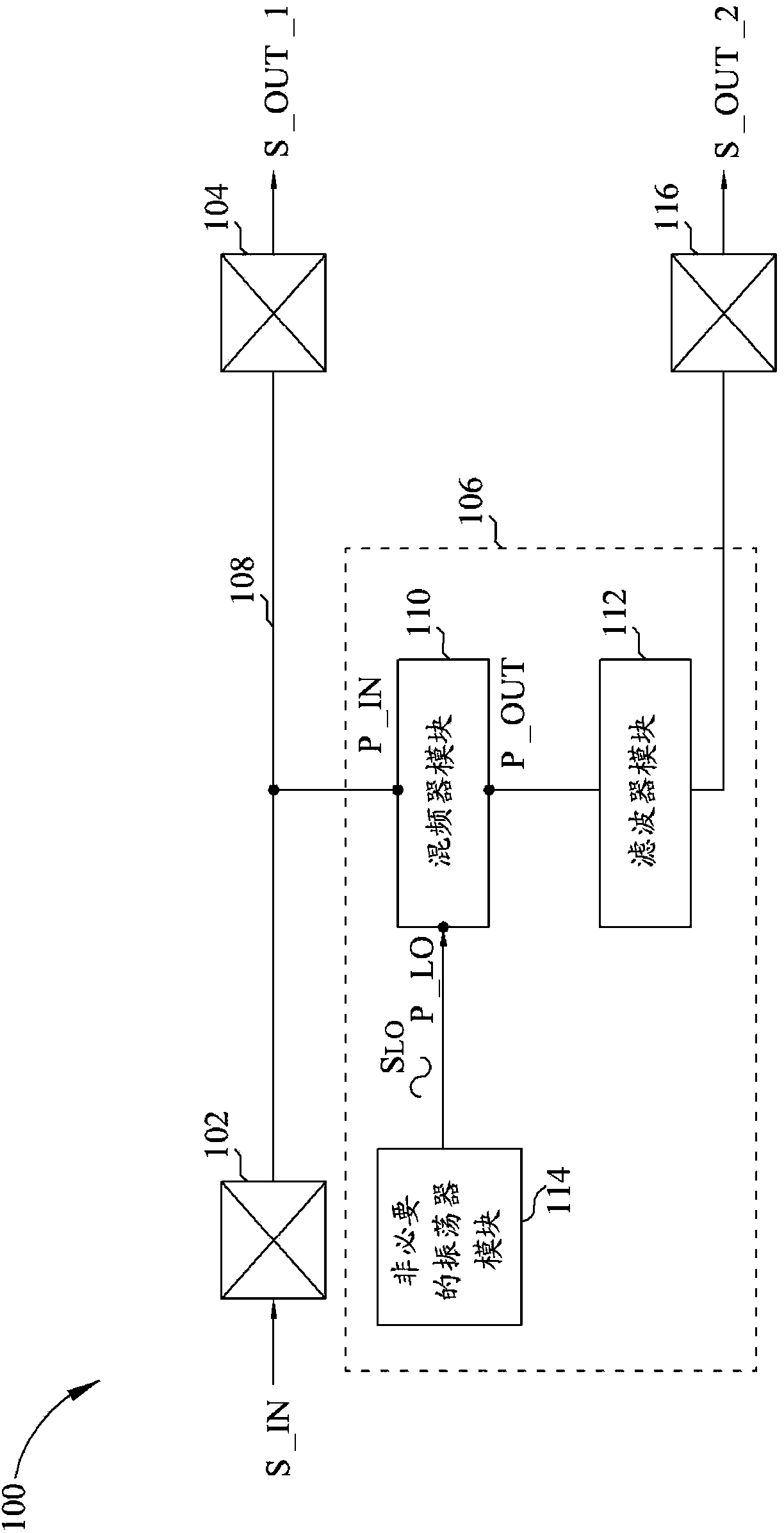

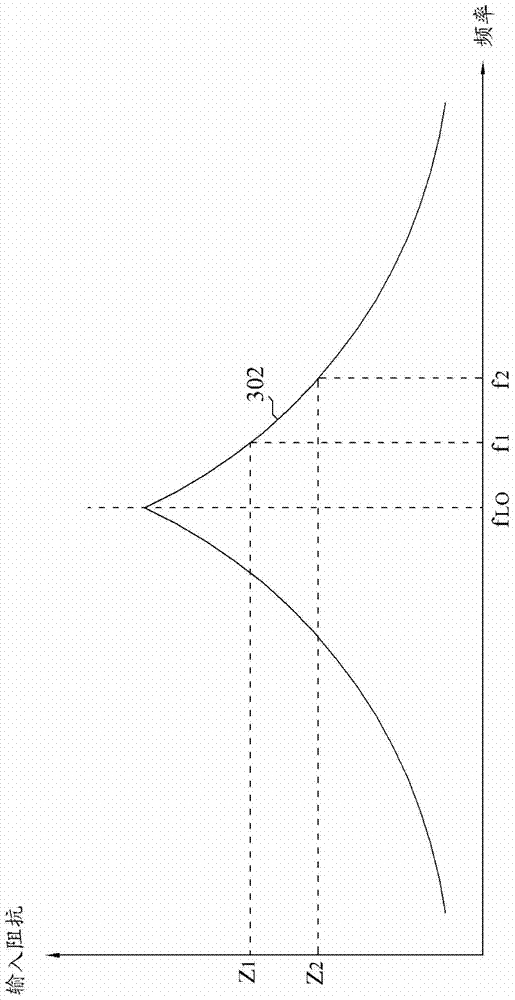

Signal processing apparatus and method for setting filtering characteristic of the same

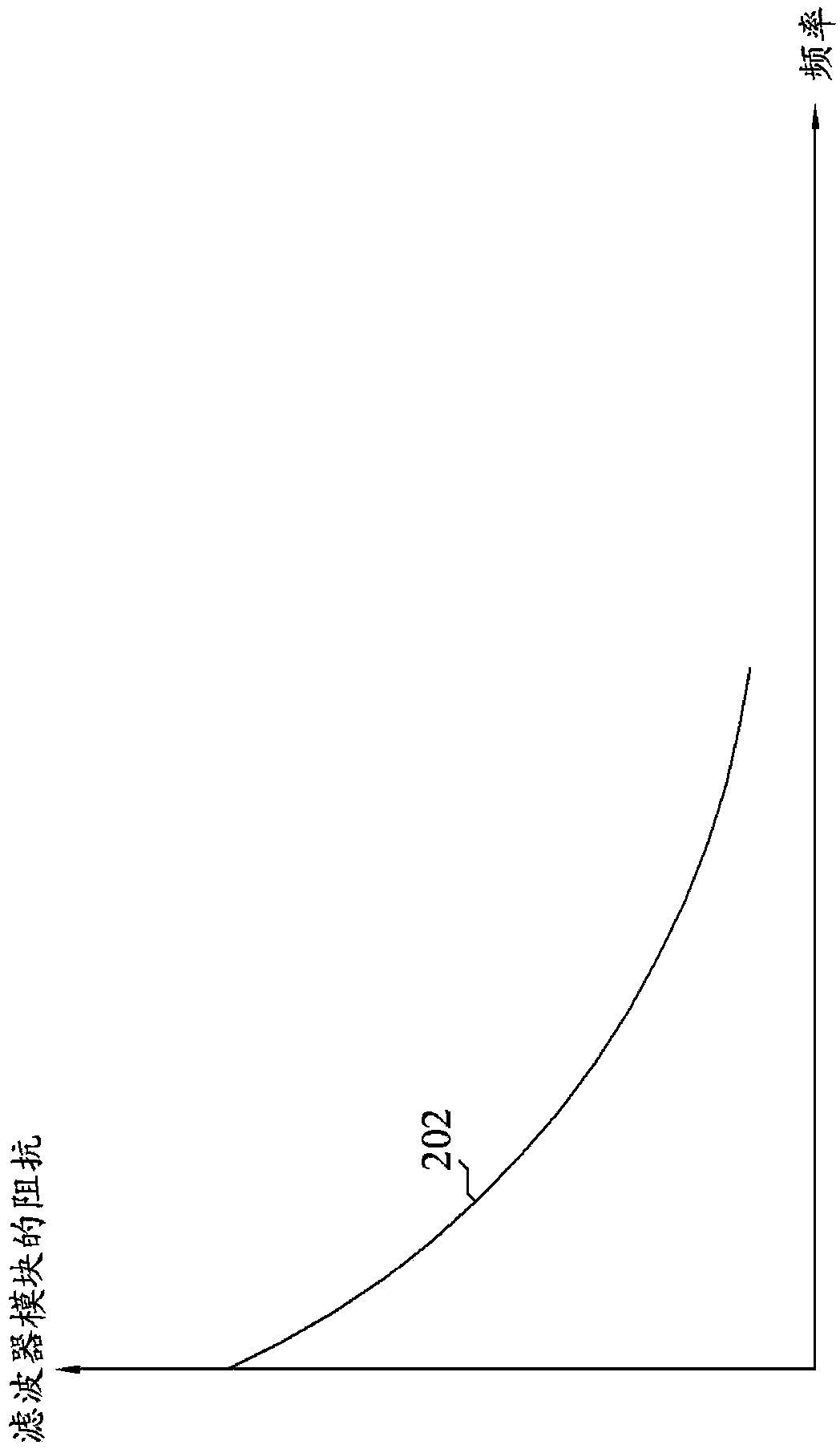

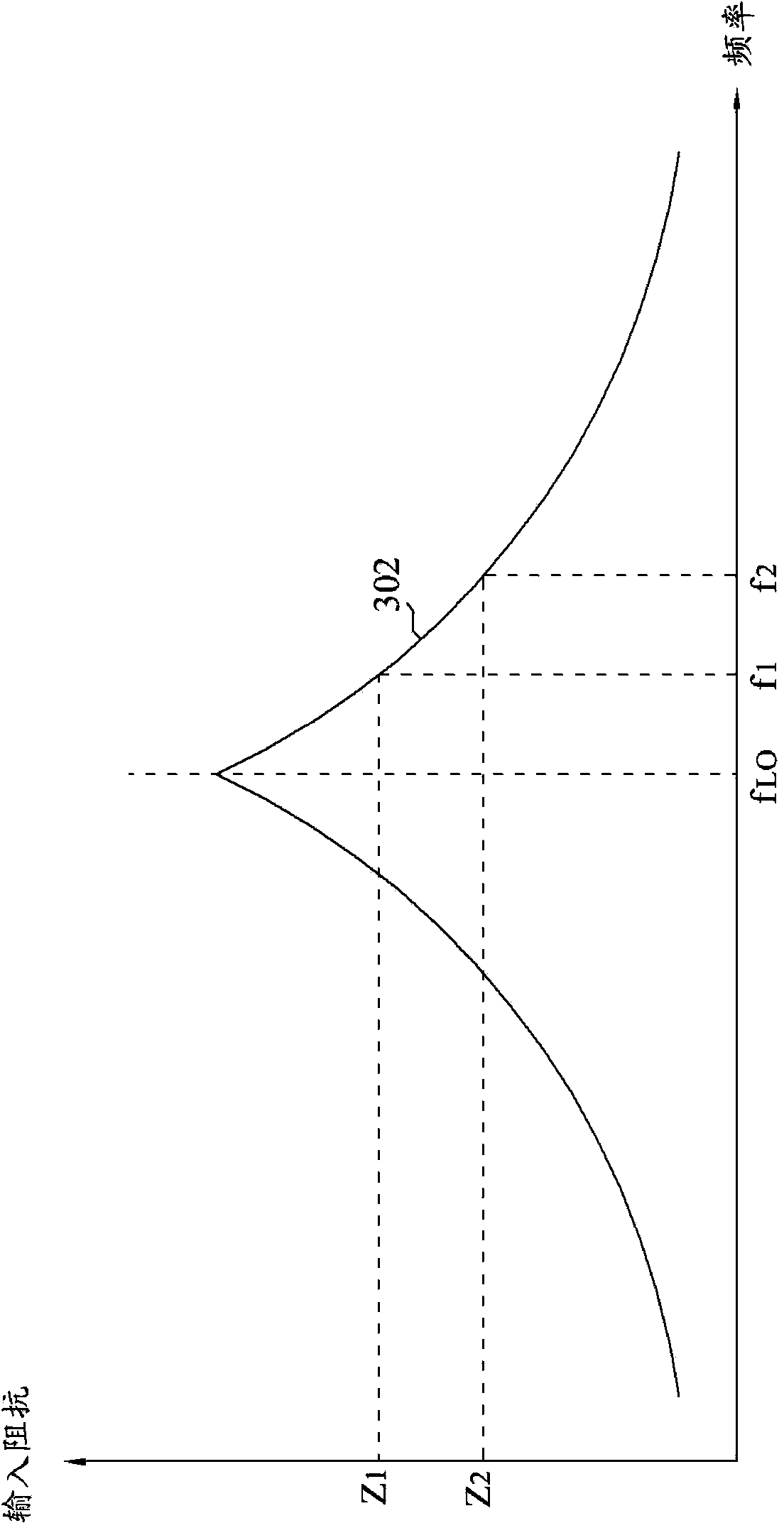

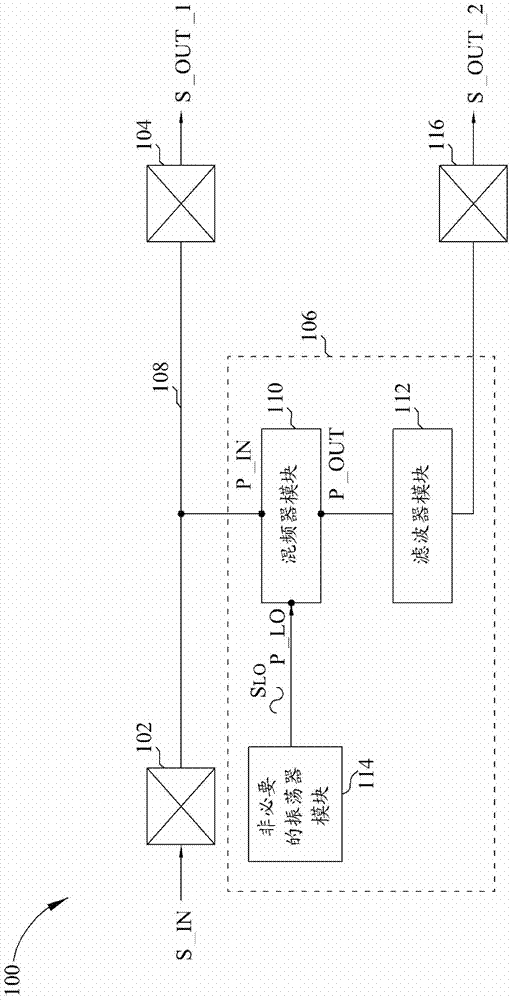

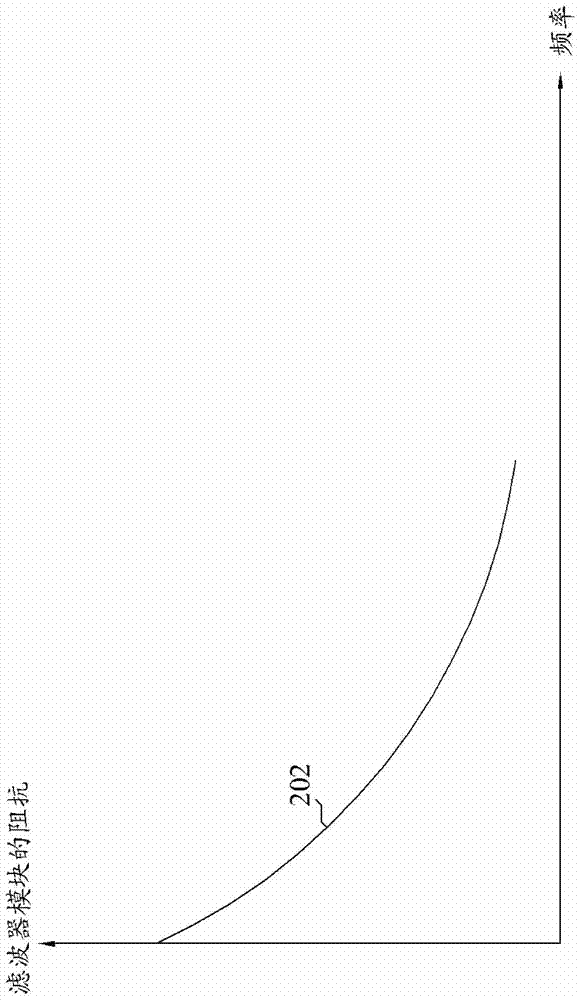

ActiveCN102195661ATo achieve the purpose of diversionSimple structureTransmissionComputer scienceSignal processing

The present invention provides a signal processing apparatus and a method for setting a filtering characteristic of the same. The method for setting the filtering characteristic of the signal processing apparatus comprises the following steps: configuring a first signal processing path; and configuring a second signal processing path. When an input signal received at the signal input port includes a first signal component with a first frequency and a second signal component with a second frequency, most of the first signal component is processed by the first signal processing path, and most of the second signal component is processed by the second signal processing path. The signal processing apparatus and the method for setting the filtering characteristic of the signal processing apparatus can effectively filter the unwanted signal component.

Owner:MEDIATEK INC

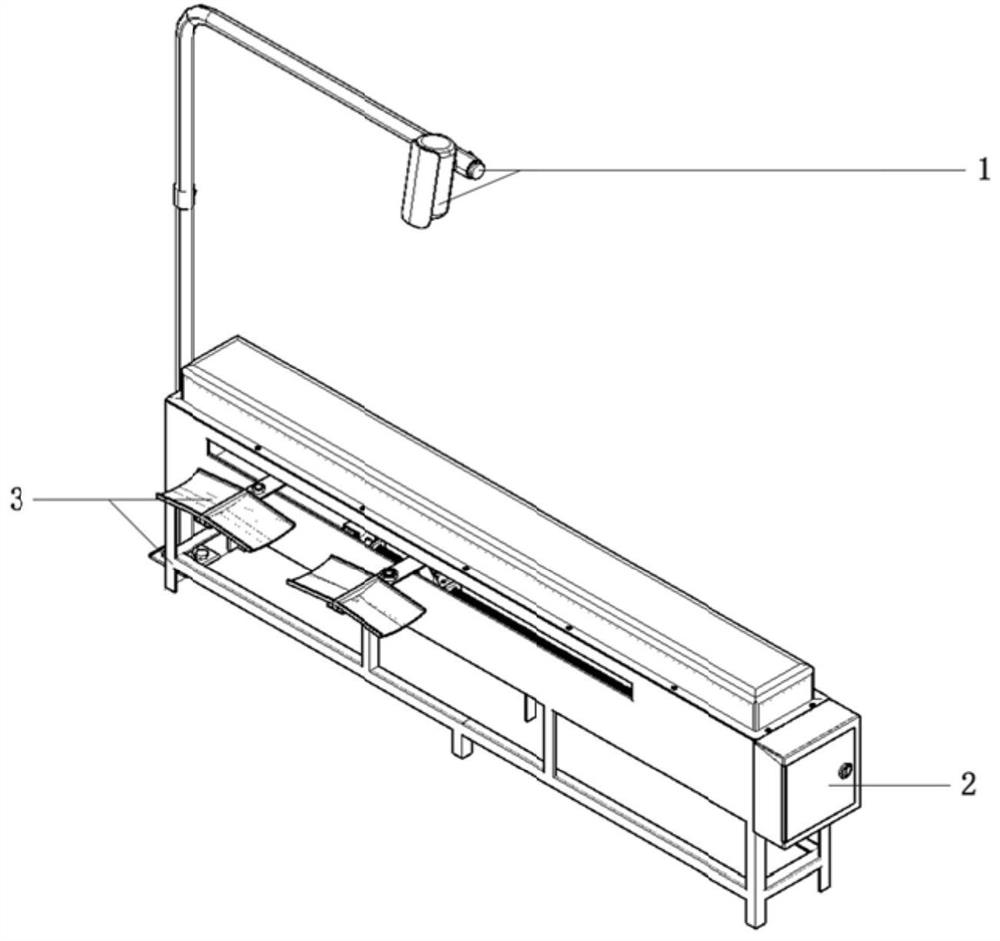

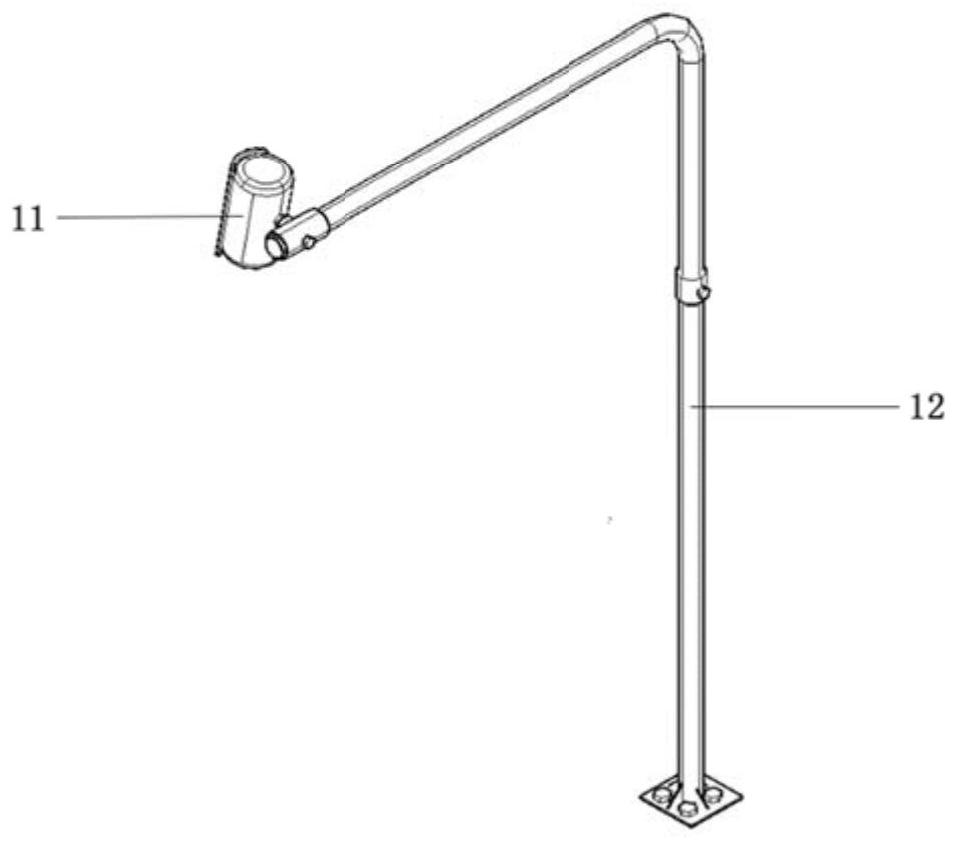

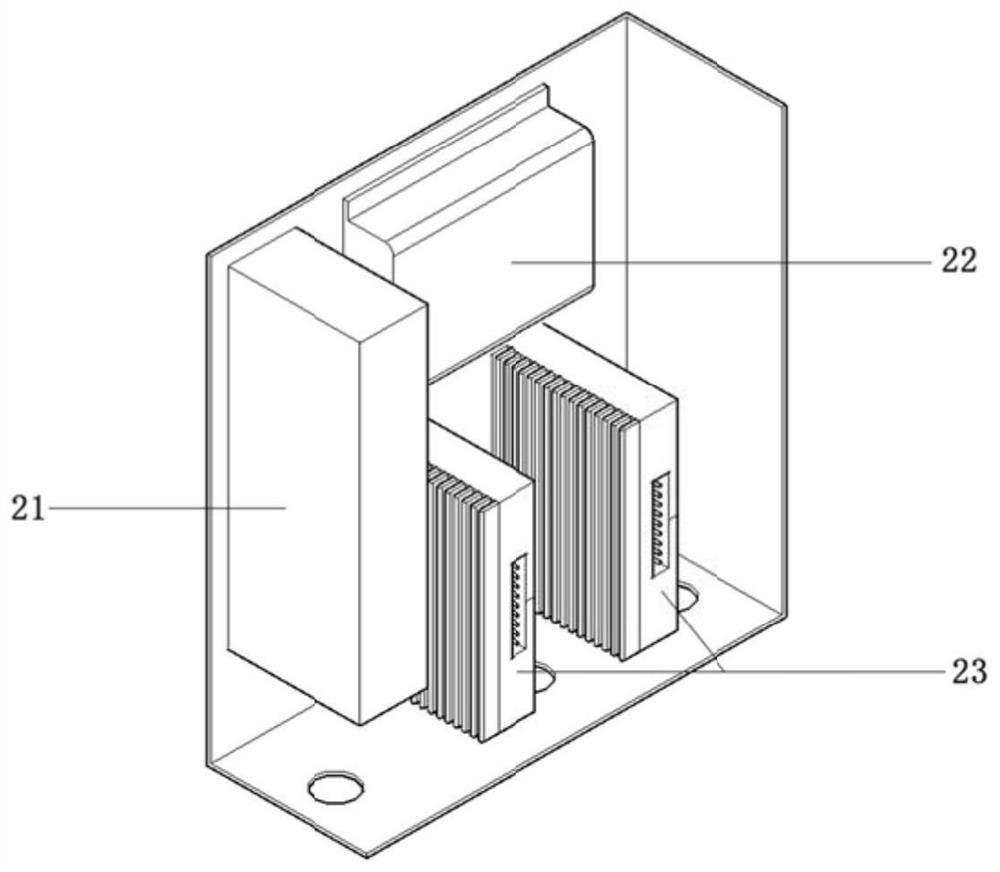

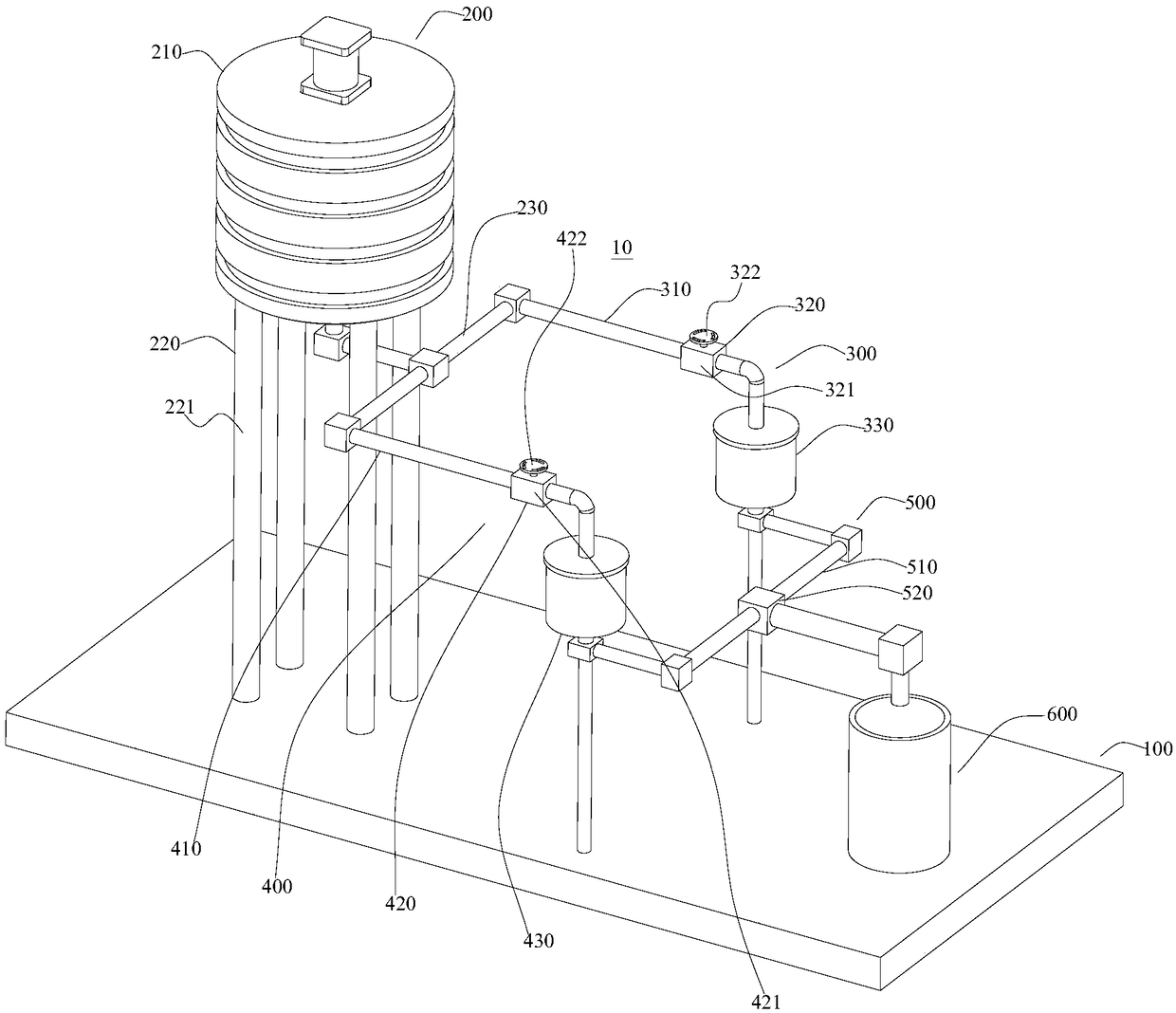

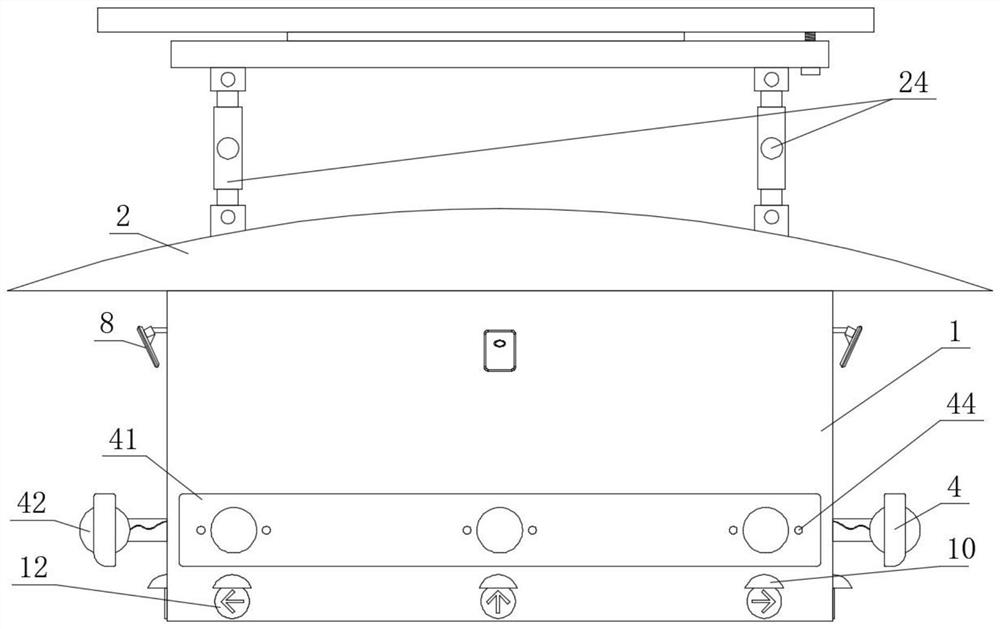

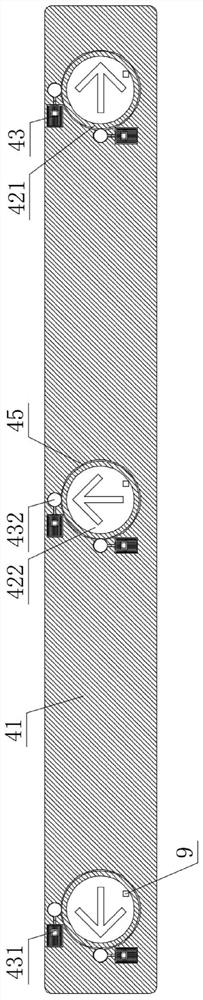

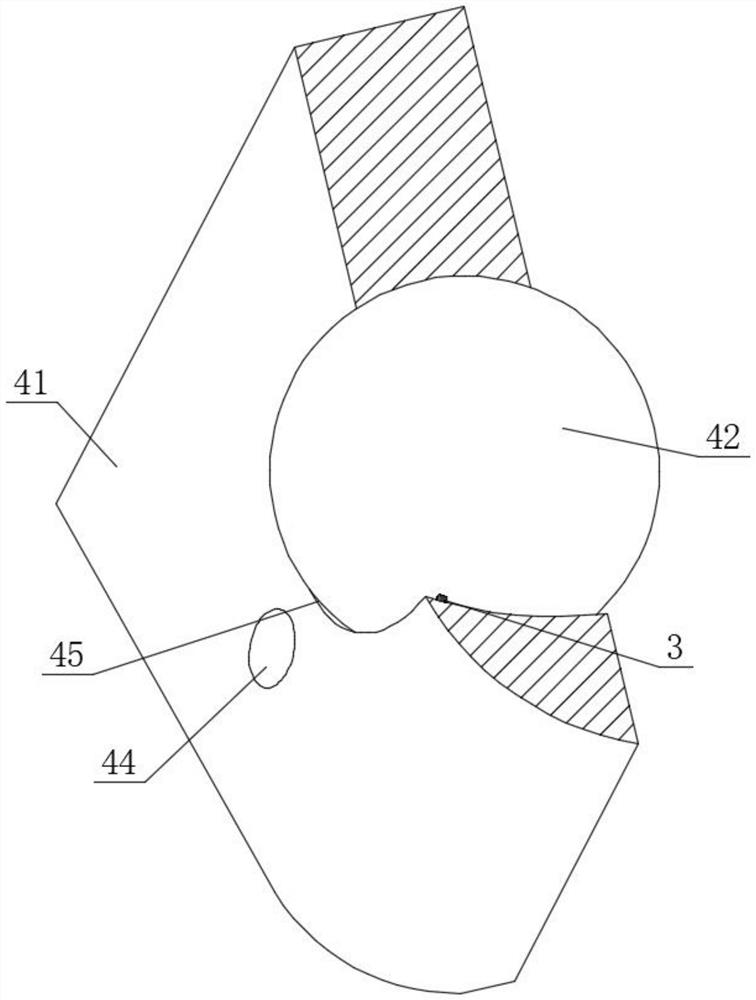

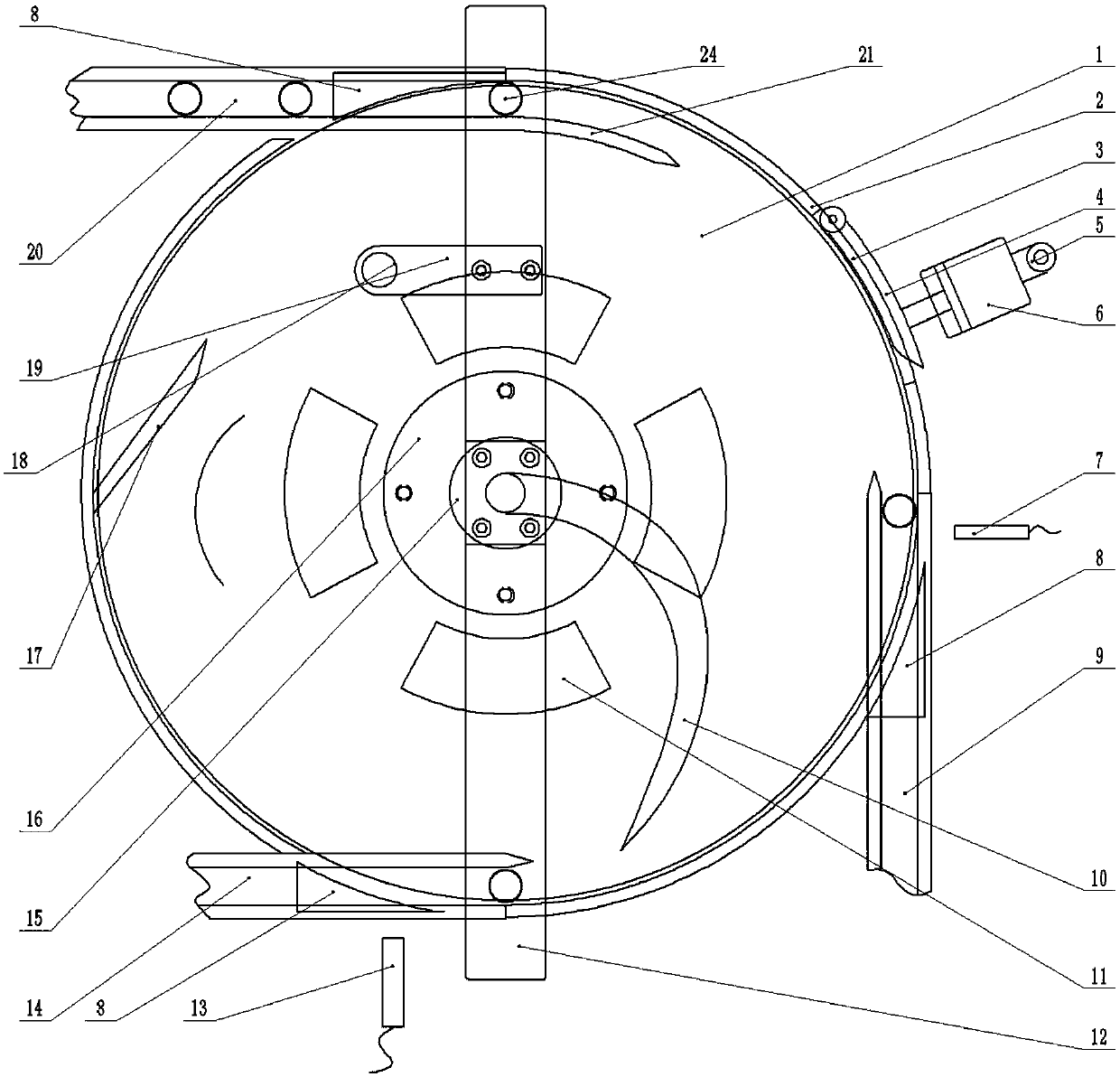

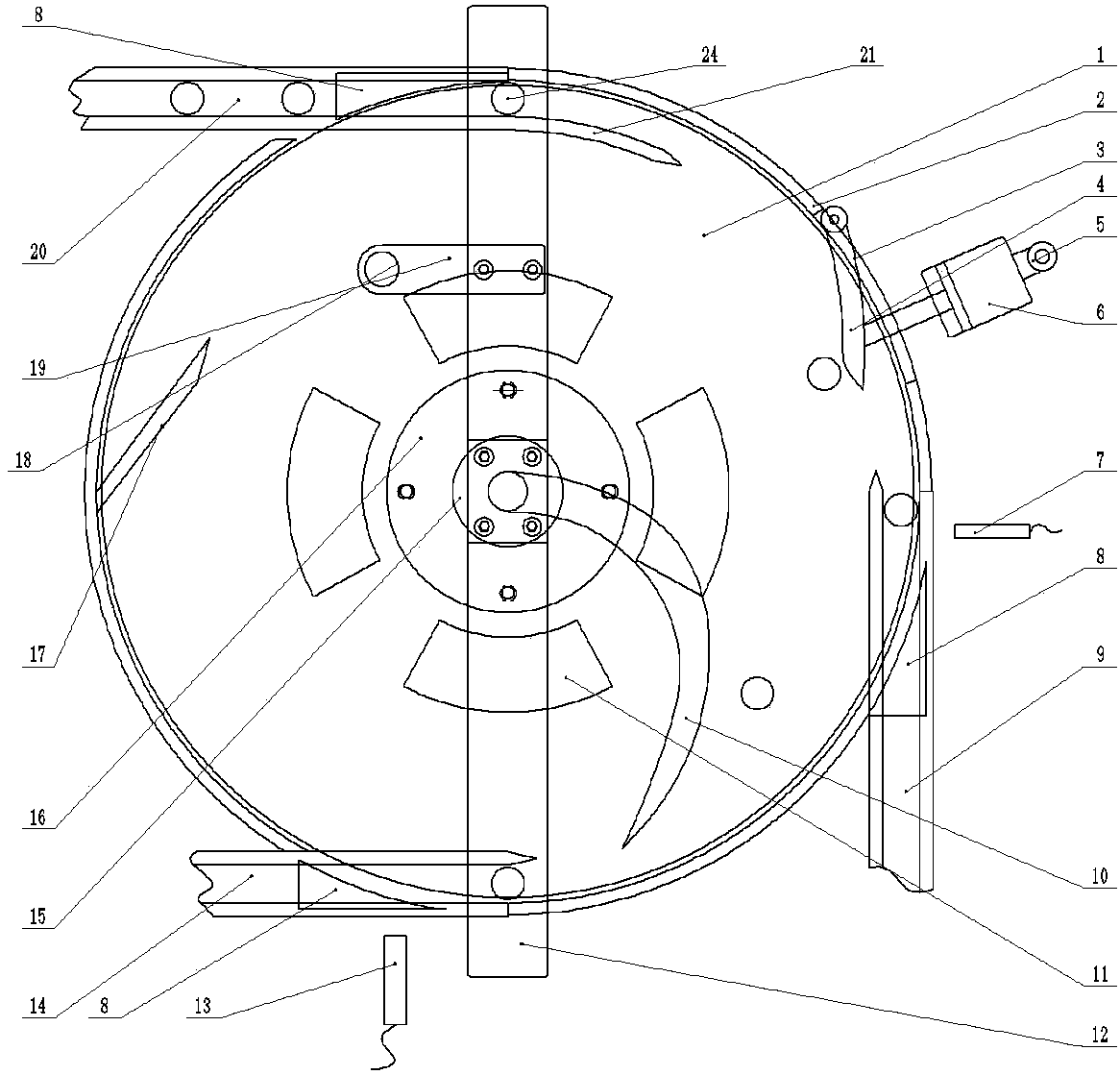

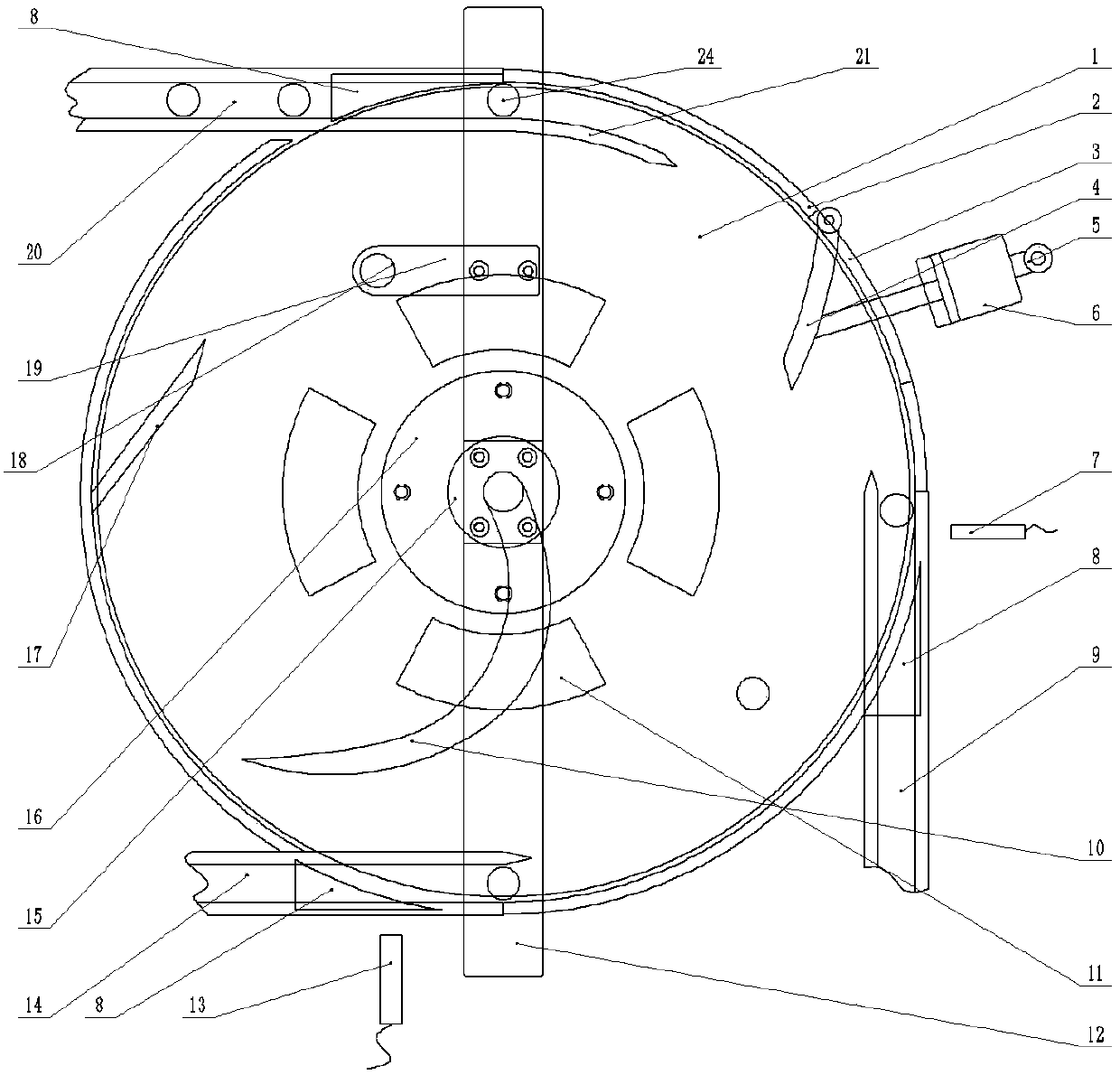

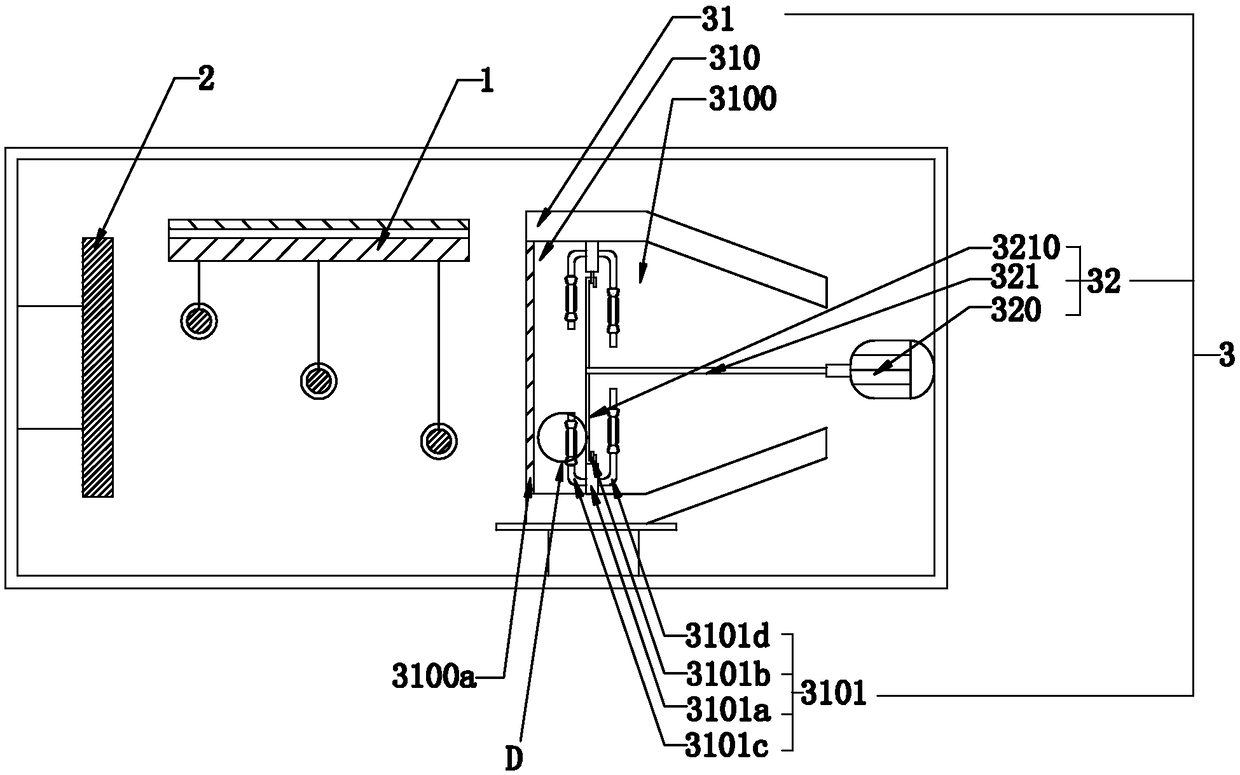

Table concentrator flow guide control system based on visual servo and table concentrator flow guide control method

InactiveCN111889222AHigh degree of automationRealize automatic beneficiationWet separationVisual servoingControl signal

The invention discloses a table concentrator flow guide control system based on a visual servo. The table concentrator flow guide control system comprises a visual acquisition unit, an operation control unit and servo flow guide mechanical devices, wherein the servo flow guide mechanical devices comprise flow guide device shells, servo sliding table sets, positioning marks and flow guide baffles,the servo sliding table sets are installed on the flow guide device shells, the flow guide baffles are installed on the servo sliding table sets and can move on the servo sliding table sets, and the positioning marks are arranged on the flow guide baffles. The visual acquisition unit acquires ore belt distribution on the surface of the table concentrator and positioning mark position coordinate pictures of the servo flow guide mechanical devices, the operation control unit operates an ore belt distribution recognition and positioning mark positioning algorithm and outputs control signals to drive the servo sliding table sets and drives the flow guide baffles to adjust the positions, and different ore belts on the surface of the table concentrator are guided into corresponding ore separating grooves through the flow guide baffles, so that automatic ore separation is achieved, the automation degree of a concentrating plant is improved, the ore separation efficiency and precision are improved, and the labor cost is greatly reduced.

Owner:湖南大奇智能科技有限公司 +2

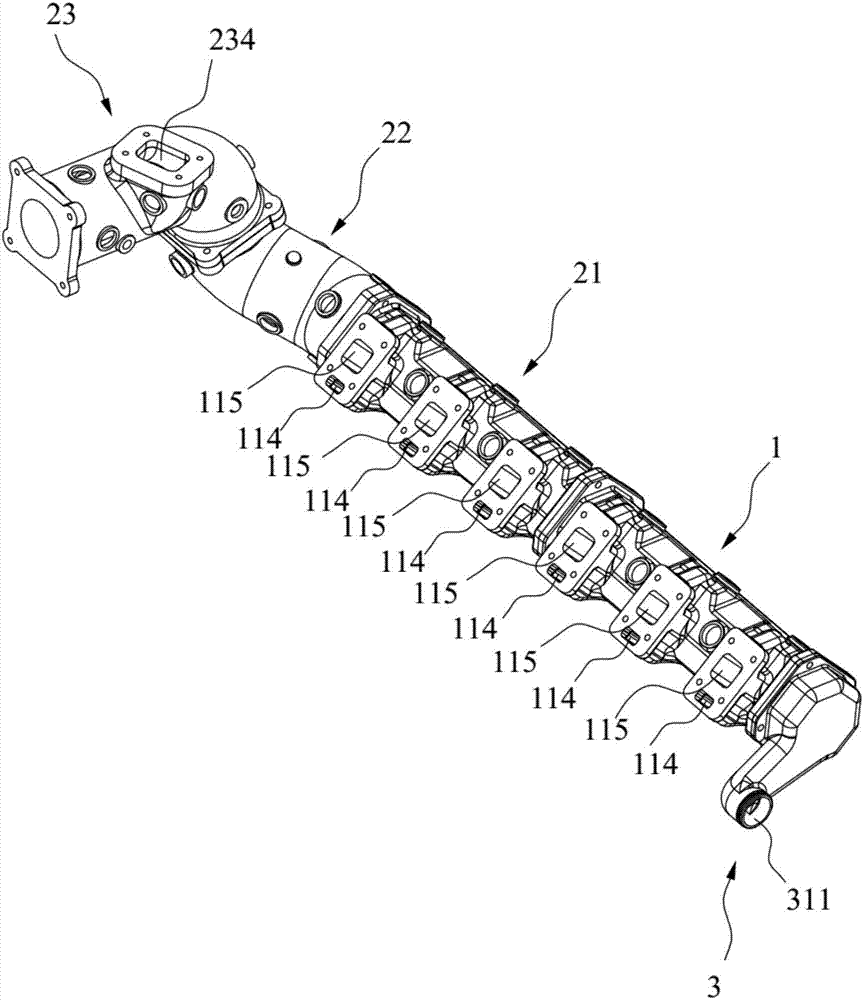

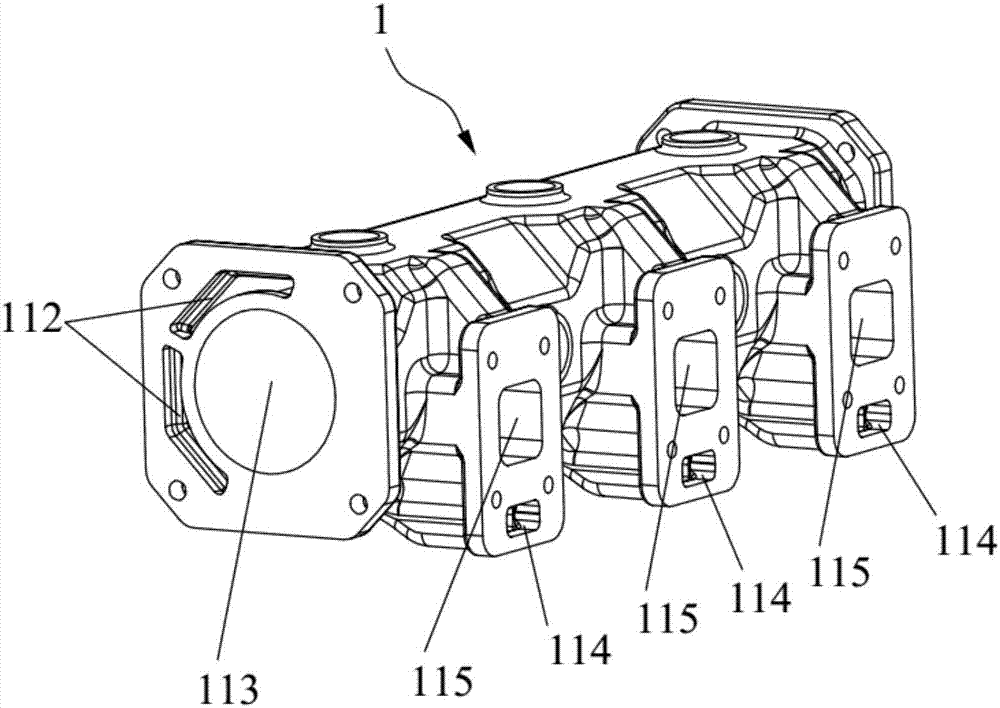

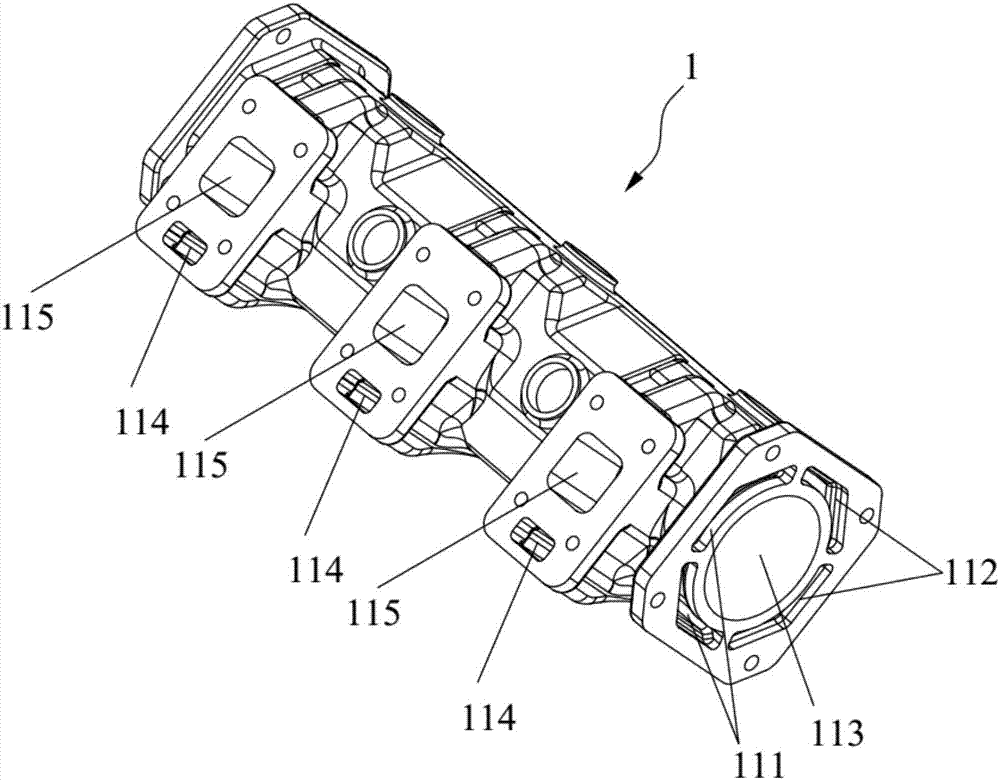

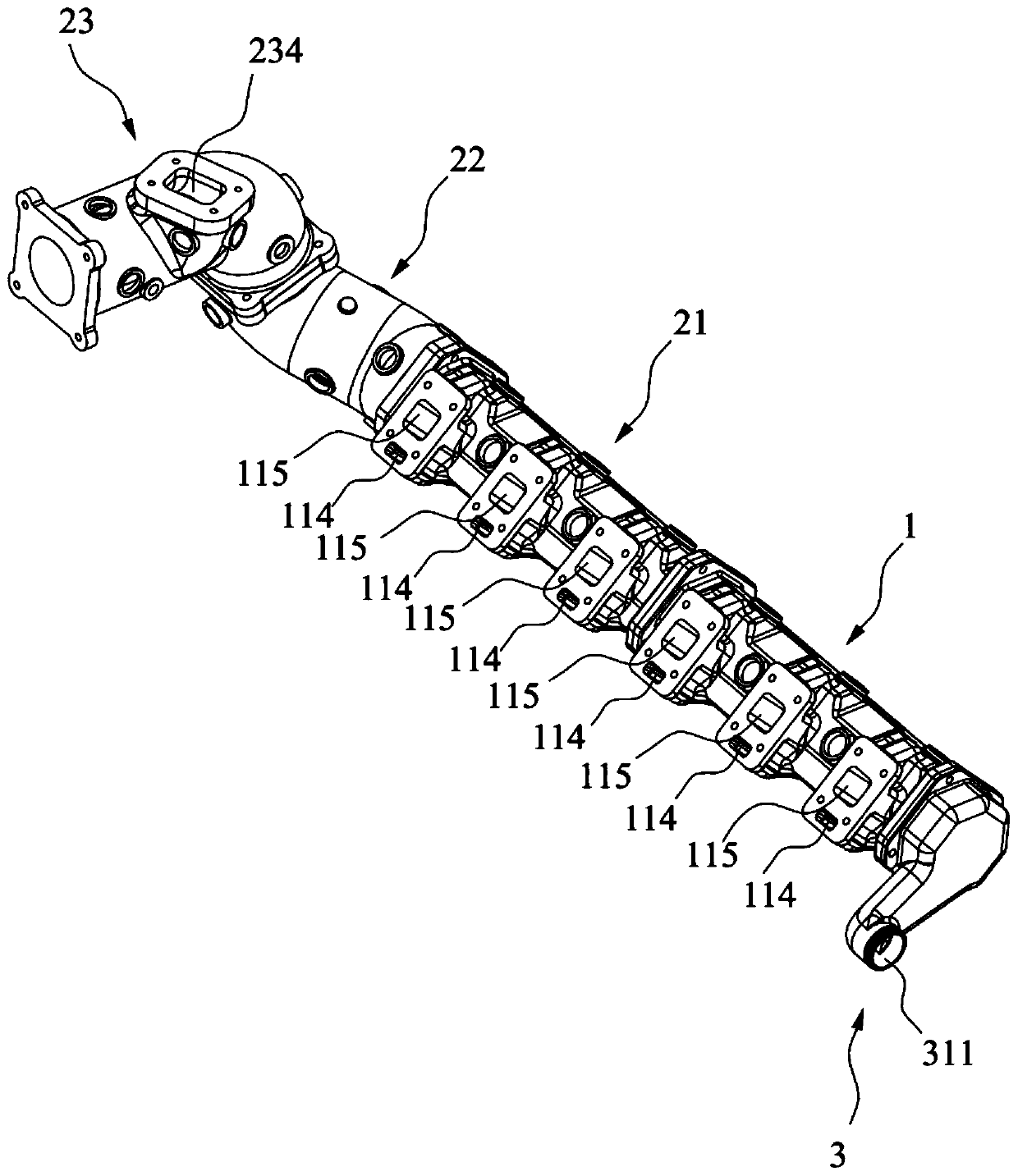

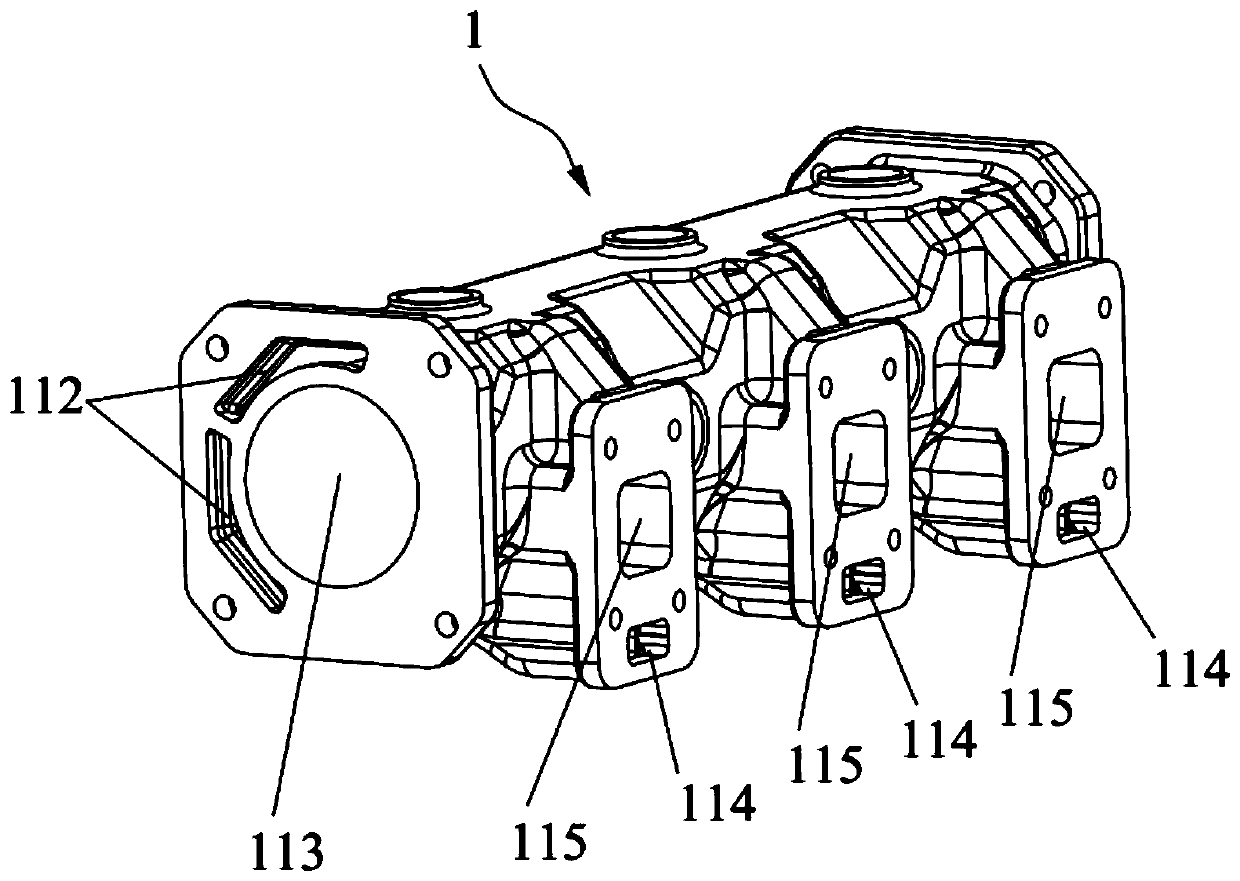

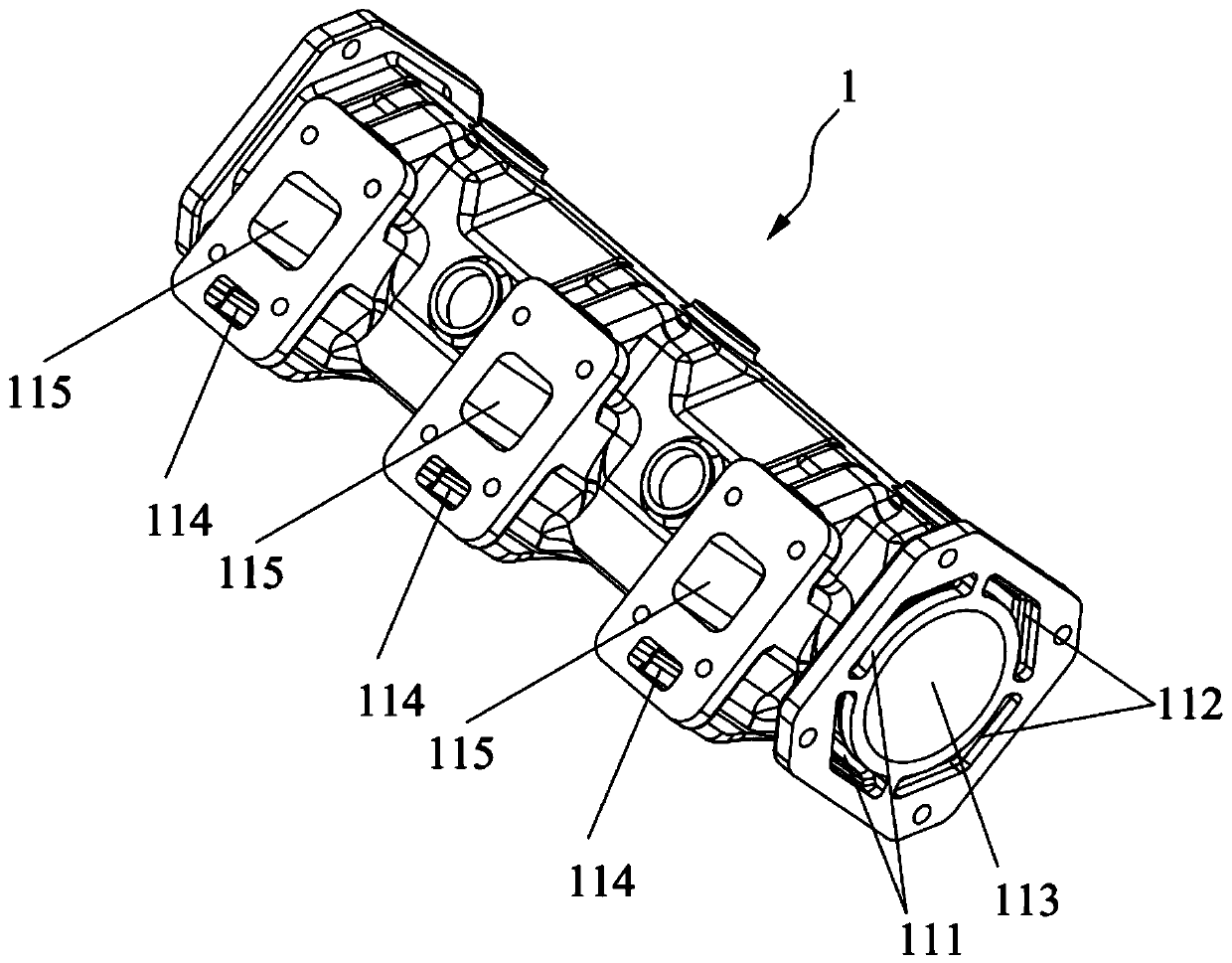

Divided cavity and divided flow type exhaust pipe assembly and engine

ActiveCN107965380AImprove compactnessTo achieve the purpose of cavityInternal combustion piston enginesExhaust apparatusEnvironmental engineeringExhaust pipe

The invention relates to the technical field of engines, and particularly relates to a divided cavity and divided flow type exhaust pipe assembly and an engine. An exhaust gas cavity as well as an exhaust port and at least two gas inlets which respectively communicate with the exhaust gas cavity are formed in the exhaust pipe assembly, and the exhaust port is located in one end of the exhaust pipeassembly; the exhaust pipe assembly further comprises water inlets, a water inlet cavity A, a water inlet cavity B, a water return cavity and a water outlet which are formed in the divided cavity anddivided flow type exhaust pipe assembly, and the number of the water inlets is the same as that of the gas inlets; the water inlet cavity A communicates with a part of water inlets; the water inlet cavity B communicates with the other part of the water inlets; the water return cavity communicates with one end, which is located at the exhaust port of the exhaust pipe assembly, of the water inlet cavity B; the water outlet is located in the other end of the exhaust pipe assembly; both the water inlet cavity A and the water return cavity communicate with the water outlet; and the engine comprises the divided cavity and divided flow type exhaust pipe assembly. The divided cavity and divided flow type exhaust pipe assembly provided by the invention has the divided cavity and divided flow functions, so that the design of the exhaust pipe assembly is compact and beautiful.

Owner:WEICHAI POWER CO LTD

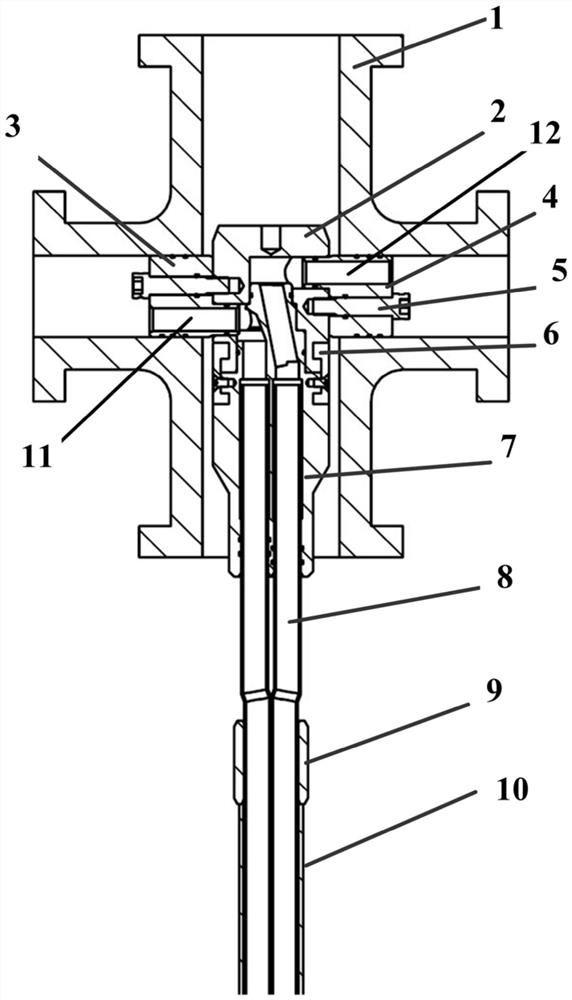

Bundled pipe wellhead multi-channel flow dividing device

ActiveCN111946289ATo achieve the purpose of diversionEnsure docking accuracyDrilling rodsSealing/packingMarine engineeringStructural engineering

The invention provides a bundled pipe wellhead multi-channel flow dividing device. The device comprises an external four-way joint, a connector assembly, a left connector and a right connector; the external four-way joint comprises an upper connection port, a lower connection port, a left connection port and a right connection port, wherein a vertical channel is formed by the upper connection portand the lower connection port, and a horizontal channel is formed by the left connection port and the right connection port; the upper end of the connector assembly is located at the intersection ofthe vertical channel and the horizontal channel, a connecting channel is formed between the upper end of the connector assembly and the vertical channel, the lower end of the connector assembly is connected with a bundled pipe assembly, and the connector assembly is provided with a first pipeline and a second pipeline, wherein the first pipeline communicates with a first bundling channel, and thesecond pipeline communicates with a second bundling channel; the left connector is detachably arranged on the side wall of the upper end of the connector assembly and located at the left connection port, the left connector is provided with a first horizontal channel, and the first horizontal channel is connected with the first pipeline; and the right connector is detachably arranged on the side wall of the upper end of the connector assembly and located at the right connection port, the right connector is provided with a second horizontal channel, and the second horizontal channel is connectedwith the second pipeline.

Owner:PETROCHINA CO LTD +3

Flow guide device for air conditioner

InactiveCN108019908AAvoid lostTo achieve the purpose of diversionLighting and heating apparatusAir-flow control membersAir volumeEngineering

The invention discloses a flow guide device for an air conditioner. The device comprises a flow guide chamber, an air blower device and an air outlet, wherein a groove in which the air blower device is clamped is formed in the middle part of the bottom part of the flow guide chamber; fixing racks are symmetrically welded and mounted at the bottom part of the inner wall of the flow guide chamber; sleeves are connected into the fixing racks by hinging, and sleeve plates are fixedly mounted on the surfaces of the sleeves. According to the device, the sleeves are symmetrically arranged at two sides of the air blower device, and the sleeve plates are fixedly mounted on the surfaces of the sleeves, so that eddy current produced at corners can be blown away, and as a result, the loss of air volume can be avoided; flow guide plates are arranged in the middle part of the flow guide chamber and can be rotated to change the direction so as to disperse air volume in the flow guide chamber, thus achieving the flow guide purpose is achieved; and meanwhile, flow distributing chambers are arranged, so that the flow guide effect can be further improved; the positions of sliding blocks can be adjusted to realize various air supplying modes, thus the air supplying efficiency is improved, and moreover, the air supplying range is expanded. The device has the characteristics of being simple in structure, and low in cost.

Owner:重庆汉美实业有限公司

Pipeline butt-joint device

InactiveCN104930288AEasy to storeTo achieve the purpose of diversionBranching pipesThreaded pipeEngineering

The invention discloses a pipeline butt-joint device which comprises a shell. A mounting groove is formed in the top of the shell. A connecting disc is arranged at the position of the mounting groove. A butt-joint hole is formed in the axis center of the connecting disc. The shell is provided with a threaded pipe and a storage cavity. The butt-joint hole is communicated with the storage cavity. The threaded pipe is communicated with the storage cavity. The shell is provided with a pipe tap communicated with the storage cavity. Liquid can be stored conveniently through the shell; liquid conveying pipelines can be connected in a butt mode through the butt-joint hole; and the aim of dividing flow can be achieved through the pipe tap and the threaded pipe, and the liquid can be divided.

Owner:郭斌

Method, device and system for detecting port link state

The embodiment of the invention discloses a port link state detection method, device and system, which relate to the field of data communication and realize that a user can perceive the link state of each member port in a link aggregation group. The method includes: receiving a test message sent by a test device, and executing a message matching policy on a message ingress port; obtaining a traffic type value in the test message, and determining traffic in a corresponding forwarding entry in a link aggregation group The member port whose type value is the same as the traffic type value in the test message, the determined member port is a member port to be tested; the test message is sent through the member port to be tested, so that the test device Determine the link state of the member port to be tested according to whether a response message to the test message is received.

Owner:MAIPU COMM TECH CO LTD

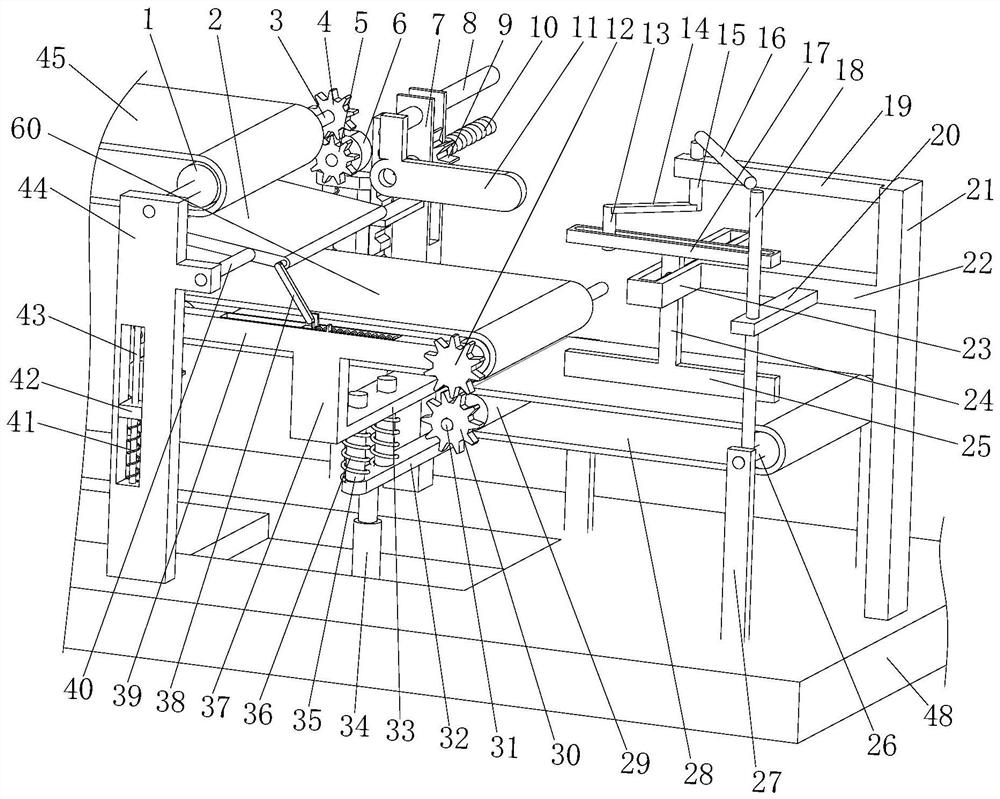

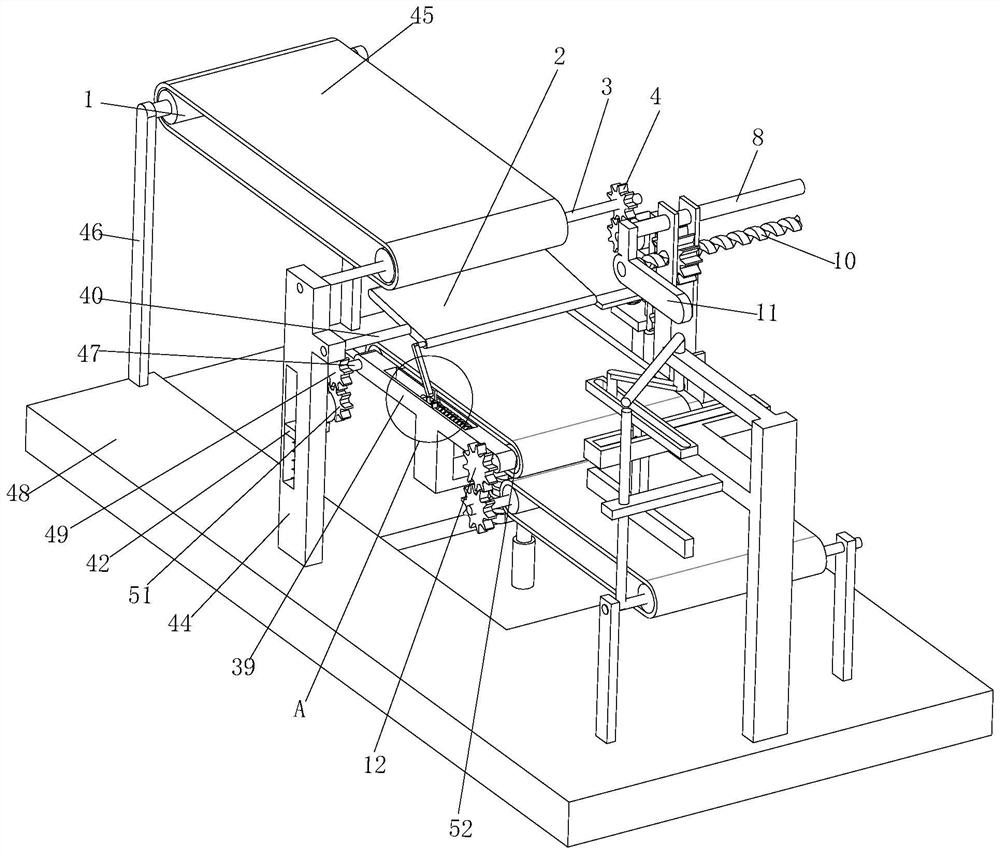

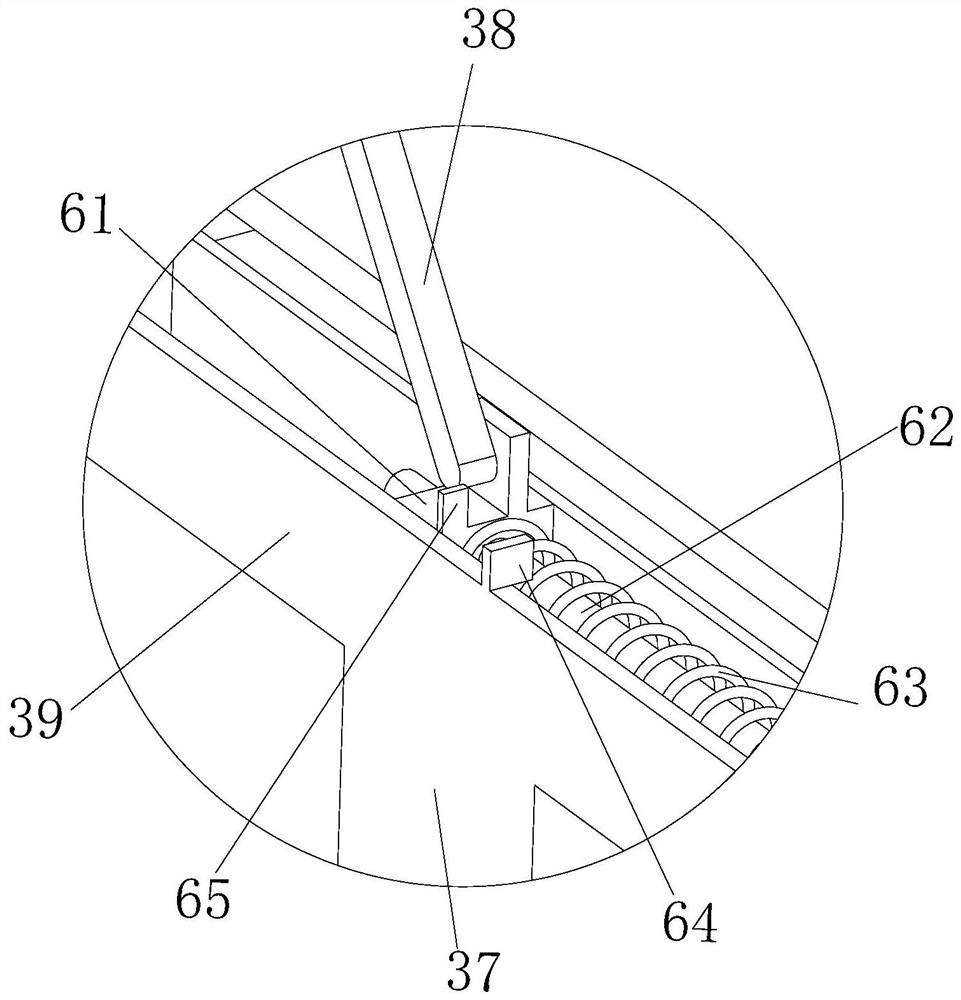

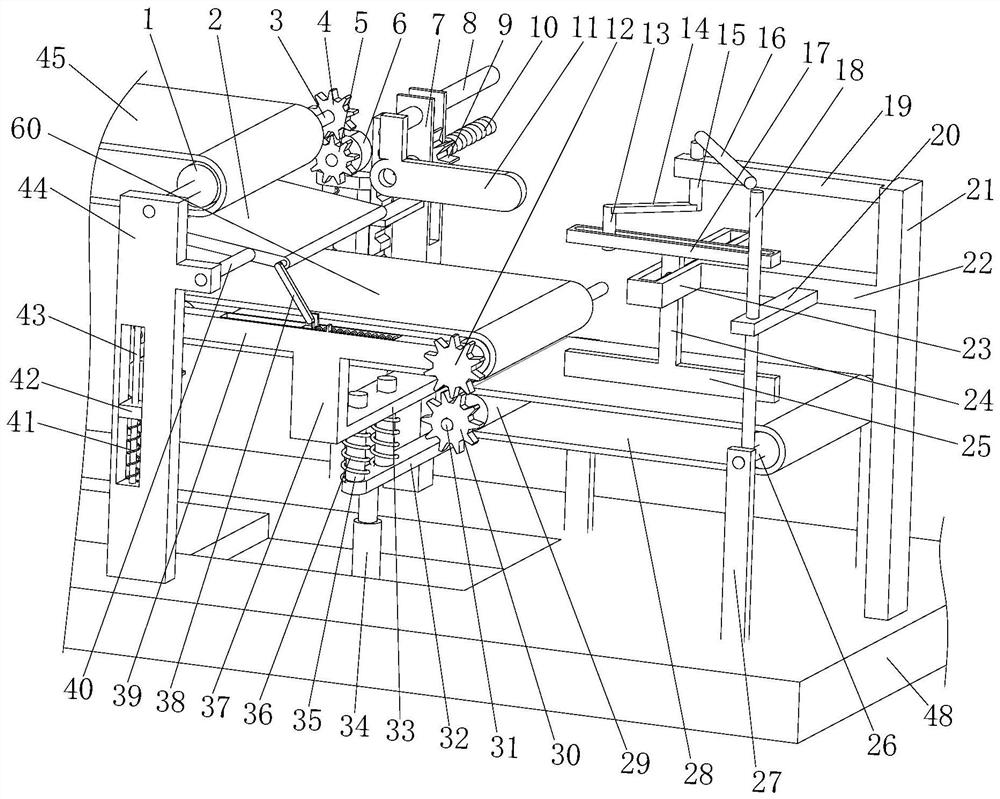

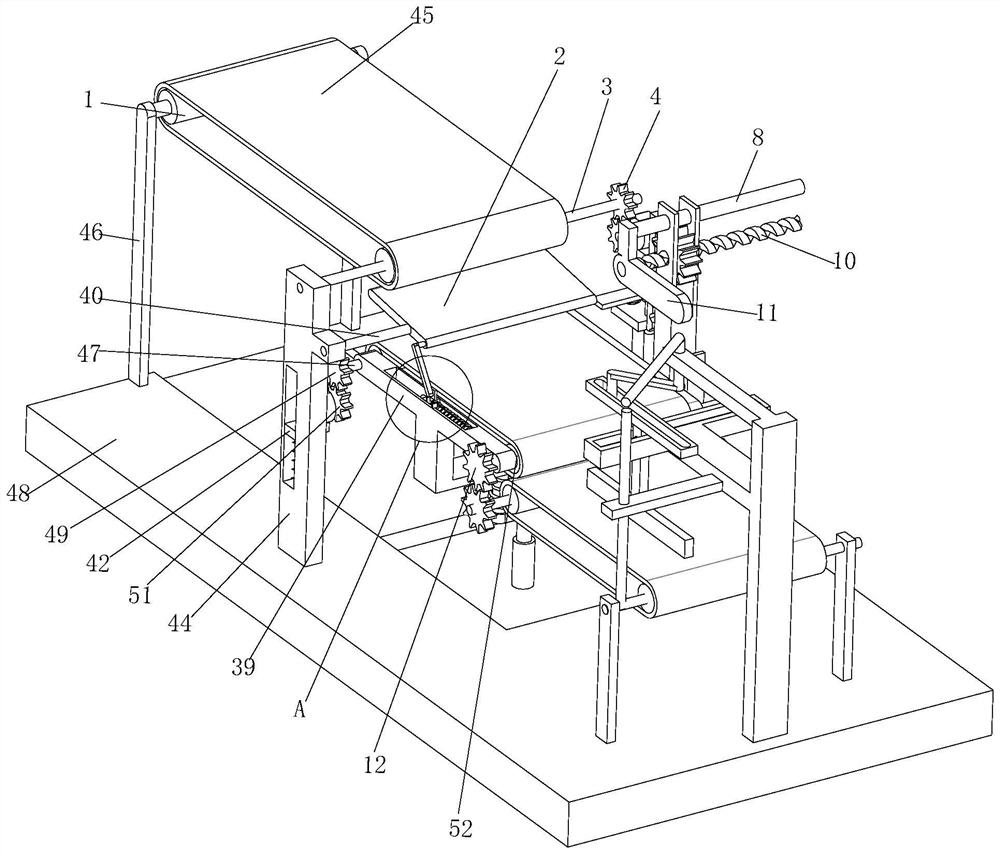

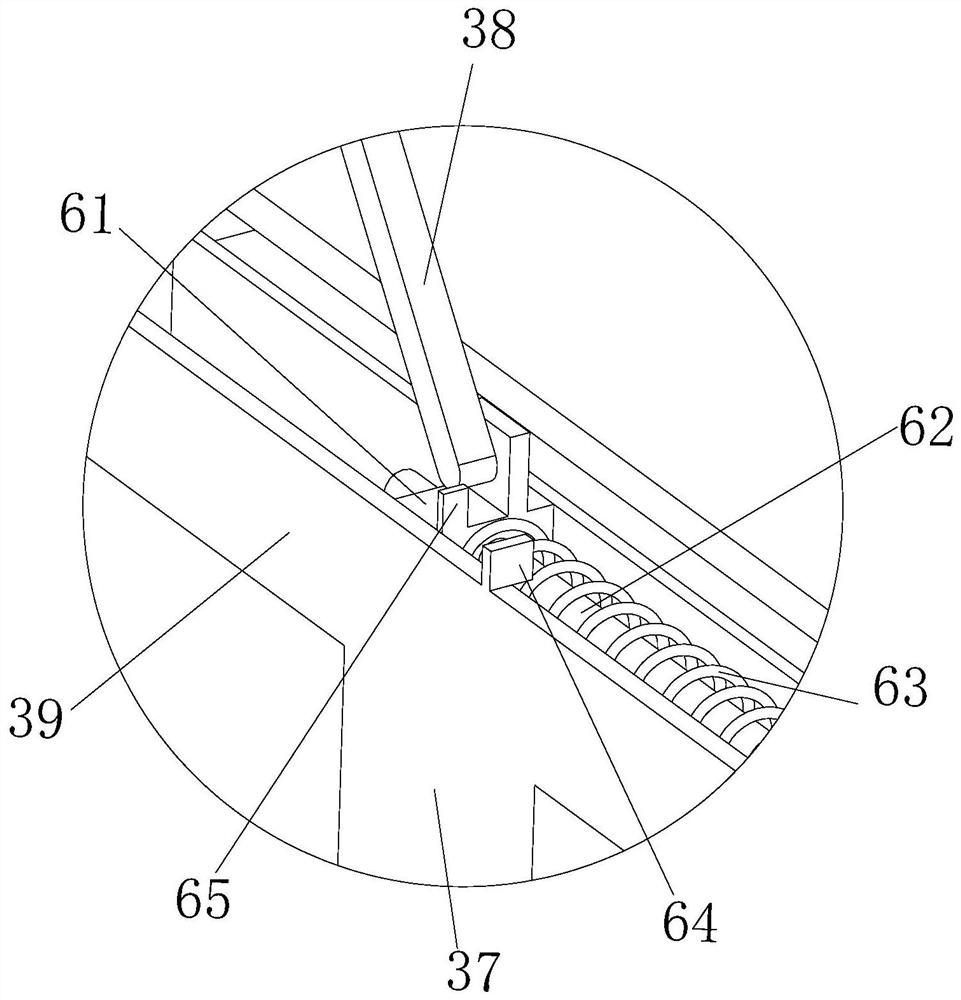

A product automatic classification storage device based on electronic storage system

ActiveCN113955371BPrevent slippingReach the sieveConveyorsControl devices for conveyorsTransmission beltConveyor belt

The present invention relates to the technical field of automatic sorting and storage equipment, in particular to an automatic sorting and storage equipment for products based on an electronic storage system. The following solution is now proposed. A roller shaft, the top surface of the base is fixedly connected with a second support rod, the first roller shaft is fixedly connected with a first column, the first column is rotatably connected with the second support rod, and a second transmission device is arranged below the first transmission device There is a rotating plate between the second conveying device and the first conveying device, one side of the rotating plate is fixedly connected with a ninth column, the ninth column is rotatably connected with the second support rod, and the second conveying device includes two third rollers The outside of the two third roller shafts is sleeved with a third conveyor belt, both sides of the third conveyor belt are provided with side bars, and the third roller shafts are rotatably connected to the side bars through the tenth column. The invention achieves the purpose of sieving and sorting out circuit boards whose parts are not completely removed during the conveying process.

Owner:浙江锐制软件技术有限公司

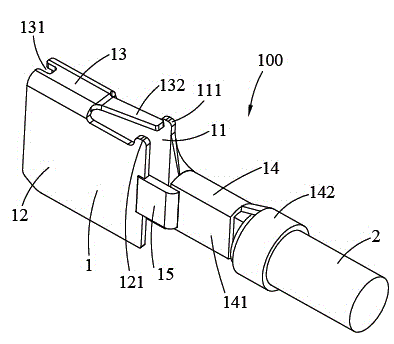

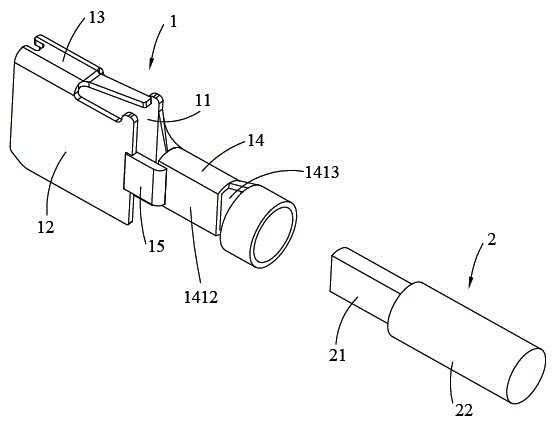

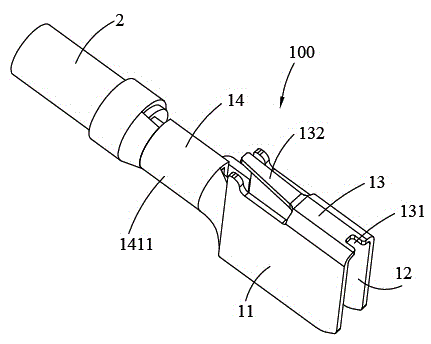

Cable assembly and power supply connector thereof

InactiveCN105161883ATo achieve the purpose of diversionCoupling contact membersTwo-part coupling devicesButt jointEngineering

The invention provides a cable assembly and a power supply connector thereof. The cable assembly comprises a conductive terminal and a cable connected to the conductive terminal. The conductive terminal comprises a first butt joint portion, a second butt joint portion parallel to the first butt joint portion, a connecting portion connected to the first and second butt joint portions, and a cable joint portion extending from the first butt joint portion. The conductive terminal also comprises an overlapping portion connected to the second butt joint portion and the cable joint portion. In this way, the first butt joint portion and the second butt joint portion can be both in direct conducting with the cable joint portion to achieve a shunting purpose.

Owner:ALLTOP ELECTRONICS SU ZHOU +1

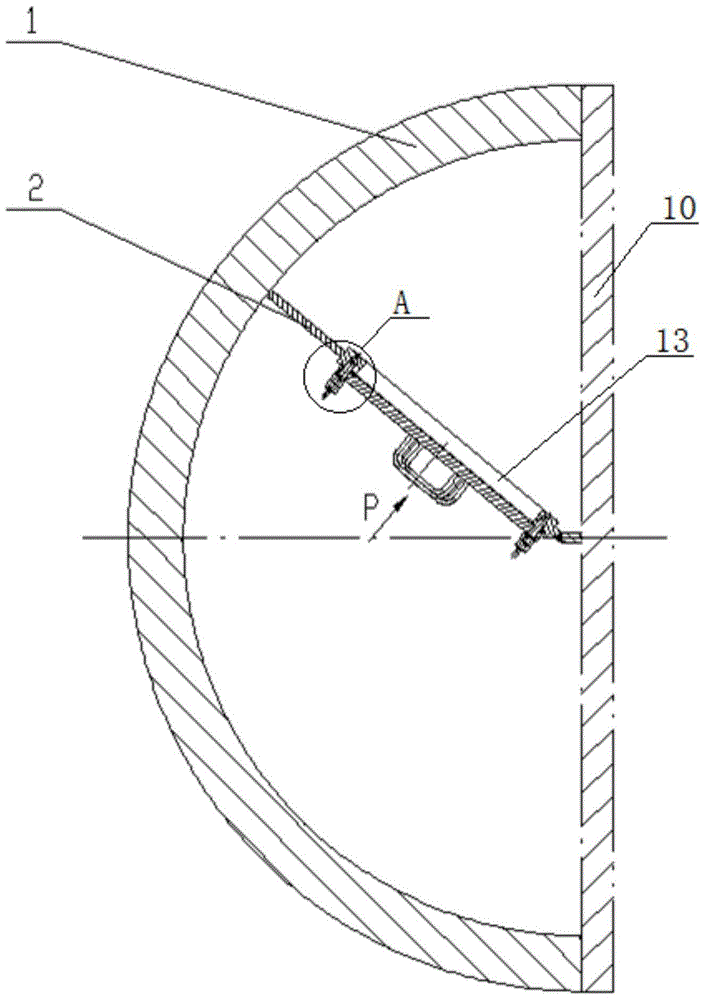

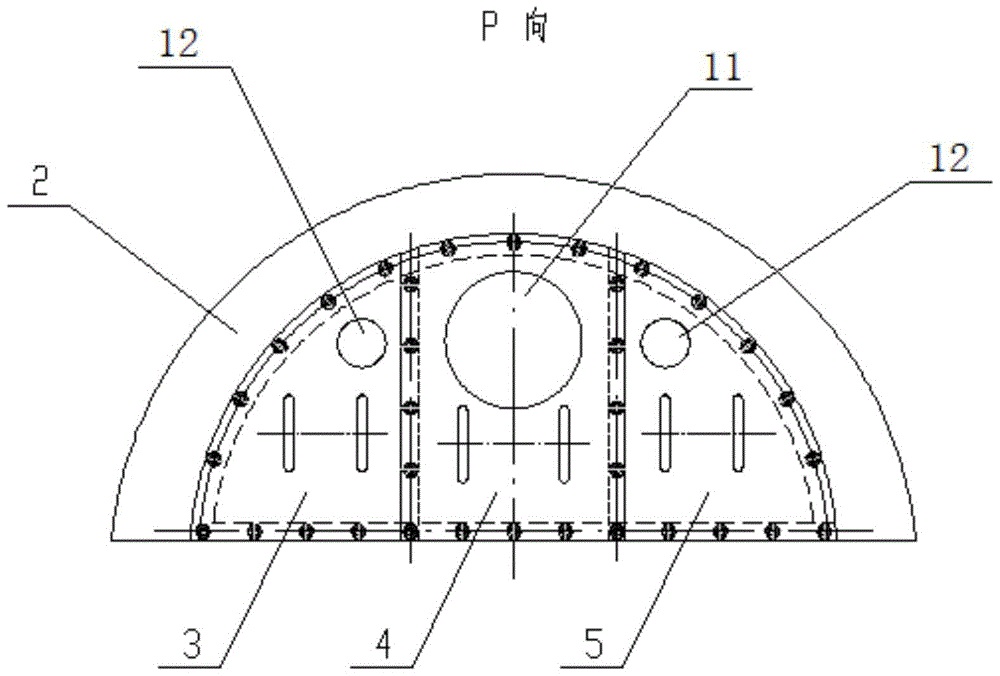

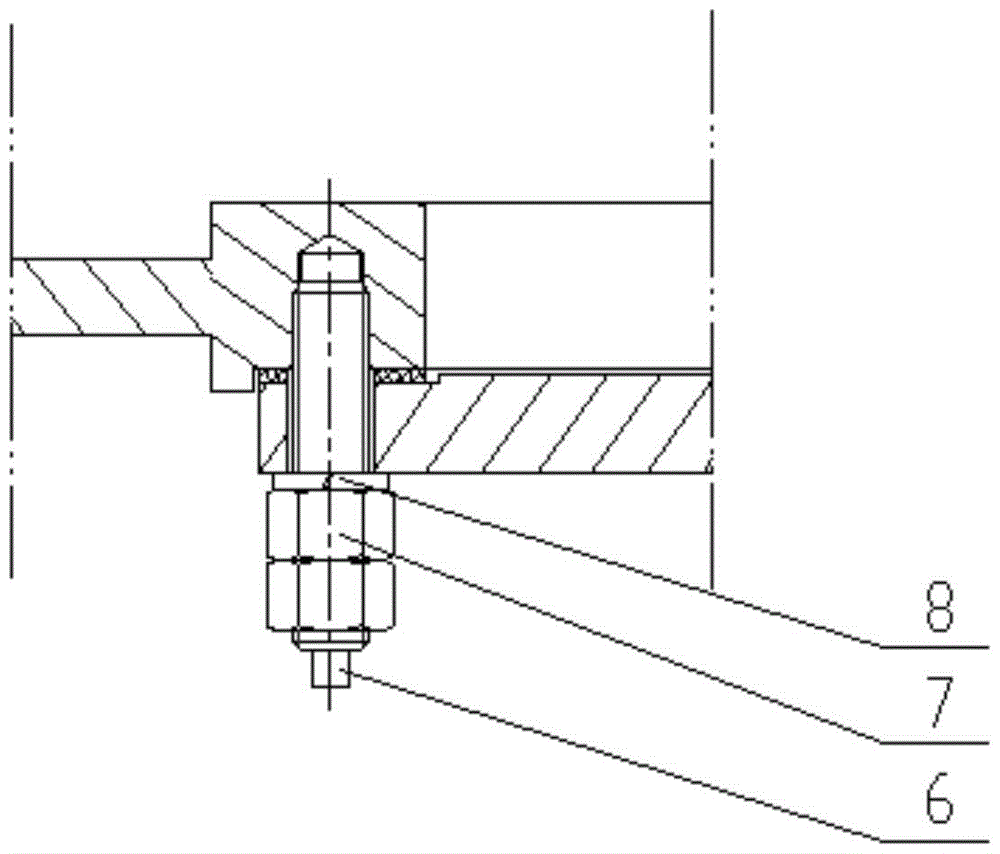

An adjustable steam cooler with built-in diversion device

ActiveCN104896461BPromote redistributionEasy to adjustFeed-water heatersPower stationAgricultural engineering

The invention discloses an adjustable steam cooler of a built-in flow distribution device, and belongs to the field of an auxiliary engine of a power station. The adjustable steam cooler comprises a route dividing clapboard arranged in a water room spherical plug end, and connected to the middle of a water room spherical plug end shell and an inner heat exchange pipe plate thereof in a sealing manner along the radial direction; a semicircular pass hole is arranged on the route dividing clapboard; a cover plate seals, covers and connects to the pass hole; the cover plate is formed by assembling a left cover plate, a middle cover plate and a right cover plate; the left, middle and right cover plates, the cover plate and the route dividing clapboard are connected in a sealing manner through a bolt, a retaining gasket and an anti-loosening nut; a main hole is arranged on the middle cover plate, and the left cover and the right cover plate are respectively provided with at least one adjusting hole for adjusting the opening and the closing; the aperture of the main hole is over two times than that of the adjusting hole. The adjustable steam cooler is simpler in structure, lower in cost, and convenient to use; the adjustable steam cooler can realize the purpose that the water flow reaches the proportional distribution at the inner part of the steam cooler; besides, the redistribution of water flow can be conveniently realized, and the flow adjusting property is good.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Polyacrylate reaction kettle with flow division function

InactiveCN109331764AAvoid cloggingTo achieve the purpose of diversionChemical/physical/physico-chemical stationary reactorsFeed devicesProcess engineering

Owner:惠州市强茂化工科技有限公司

Product automatic classification and storage equipment based on electronic warehousing system

ActiveCN113955371APrevent slippingReach the sieveConveyorsControl devices for conveyorsMechanical engineering

The invention relates to the technical field of automatic classification and storage equipment, in particular to product automatic classification and storage equipment based on an electronic warehousing system. The following scheme is put forward. The product automatic classification and storage equipment comprises a base, a first conveying device is arranged above the base and comprises first roller shafts, and a second supporting rod is fixedly connected to the top surface of the base. The corresponding first roller shaft is fixedly connected with a first column, the first column is rotationally connected with the second supporting rod, a second conveying device is arranged below the first conveying device, a rotating plate is arranged between the second conveying device and the first conveying device, one side of the rotating plate is fixedly connected with a ninth column, and the ninth column is rotationally connected with the second supporting rod. The second conveying device comprises two third roller shafts, the two third roller shafts are sleeved with a third conveying belt, side rods are arranged on the two sides of the third conveying belt correspondingly, and the third roller shafts are rotationally connected with the side rods through tenth columns. According to the product automatic classification and storage equipment, the purpose of screening and sorting out circuit boards of which parts are not completely disassembled in the conveying process is achieved.

Owner:浙江锐制软件技术有限公司

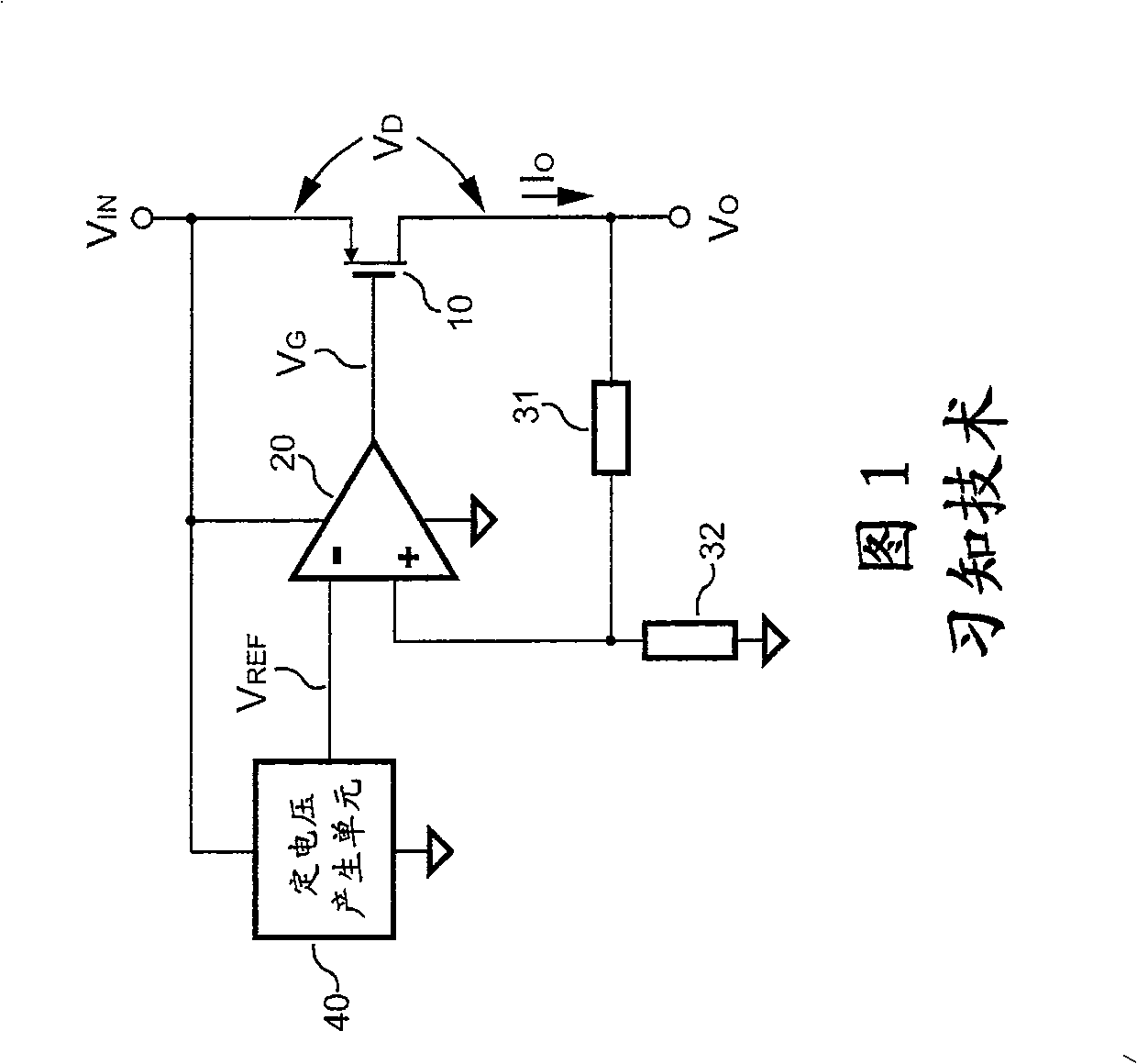

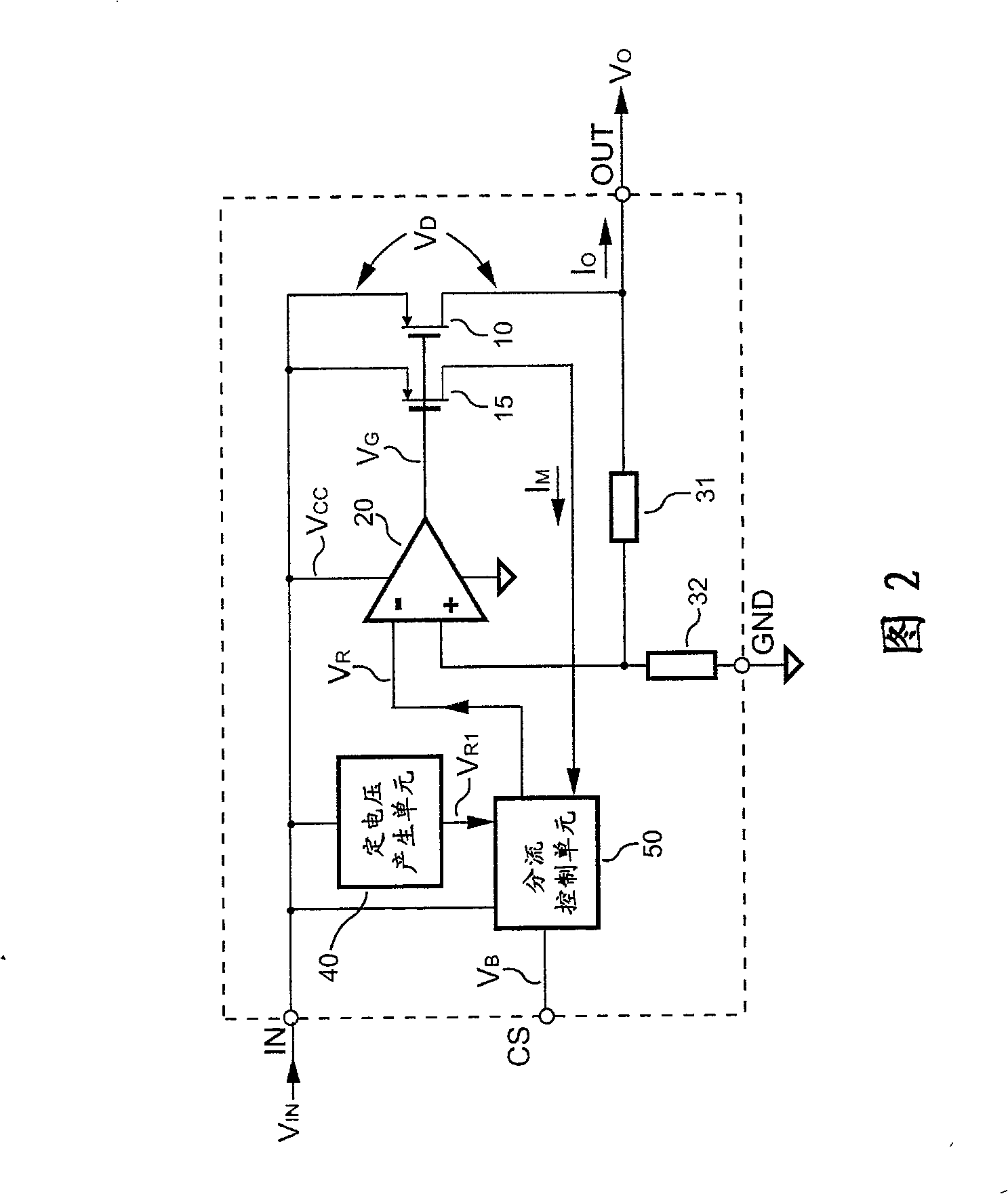

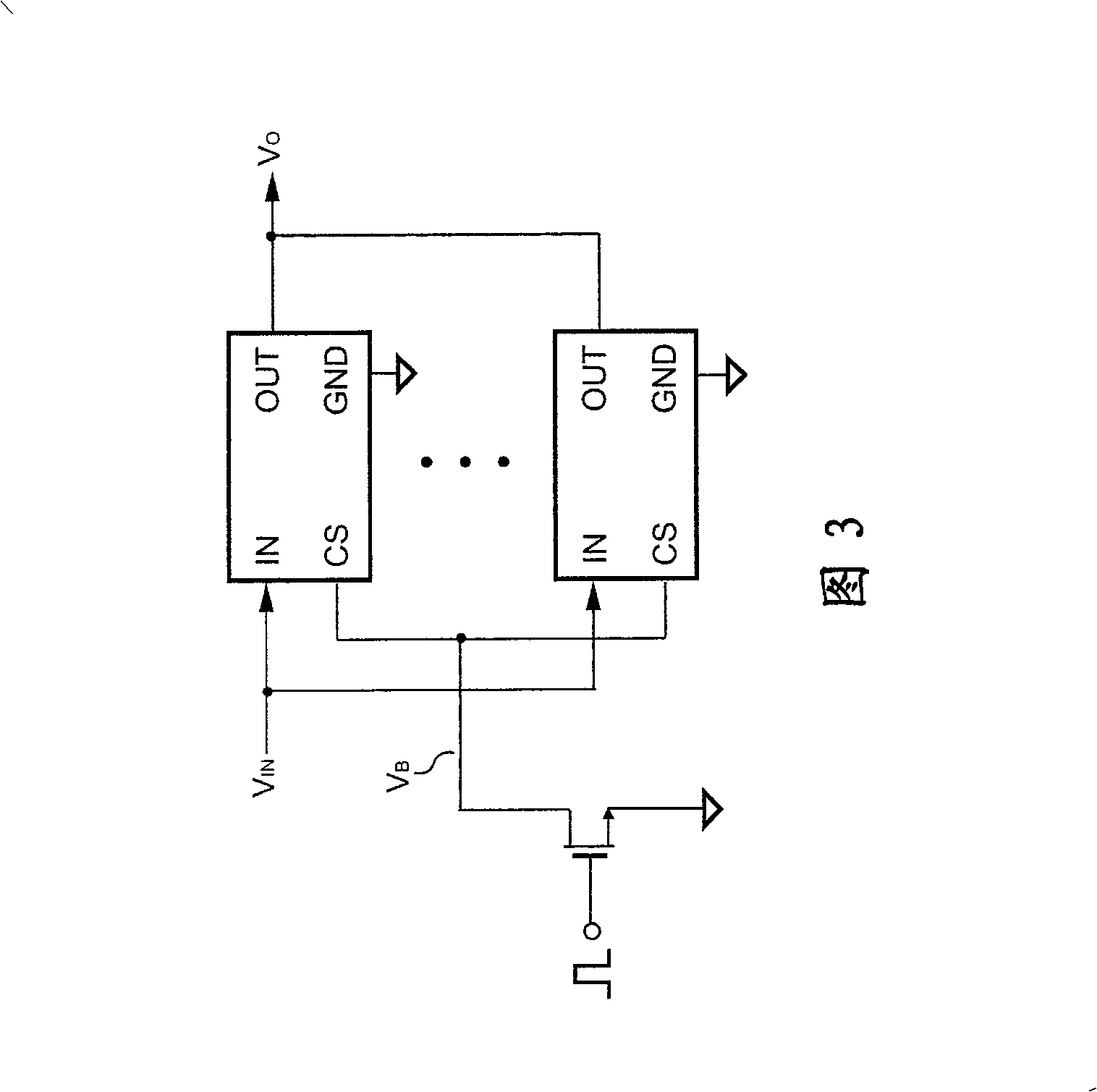

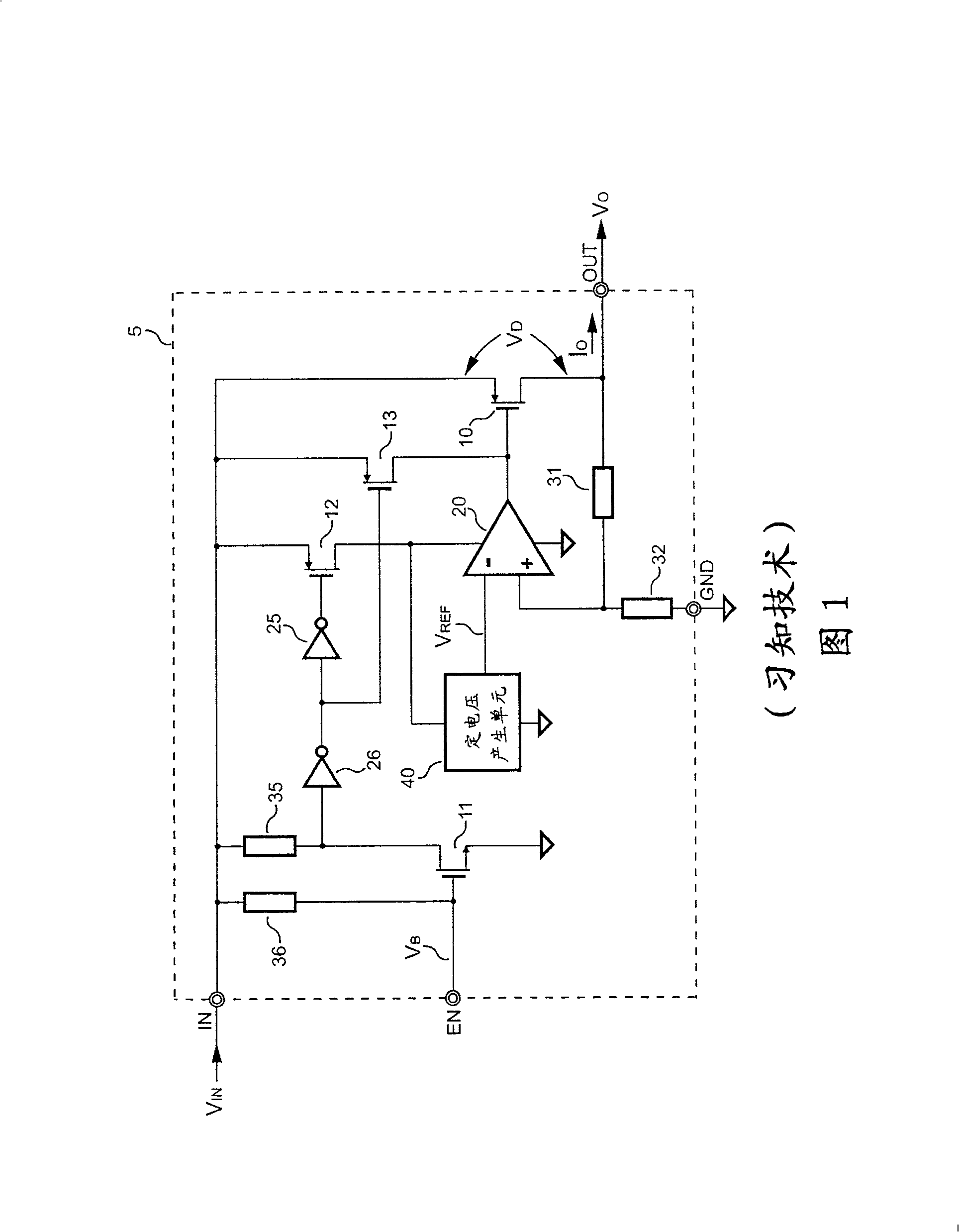

Shunting device and method

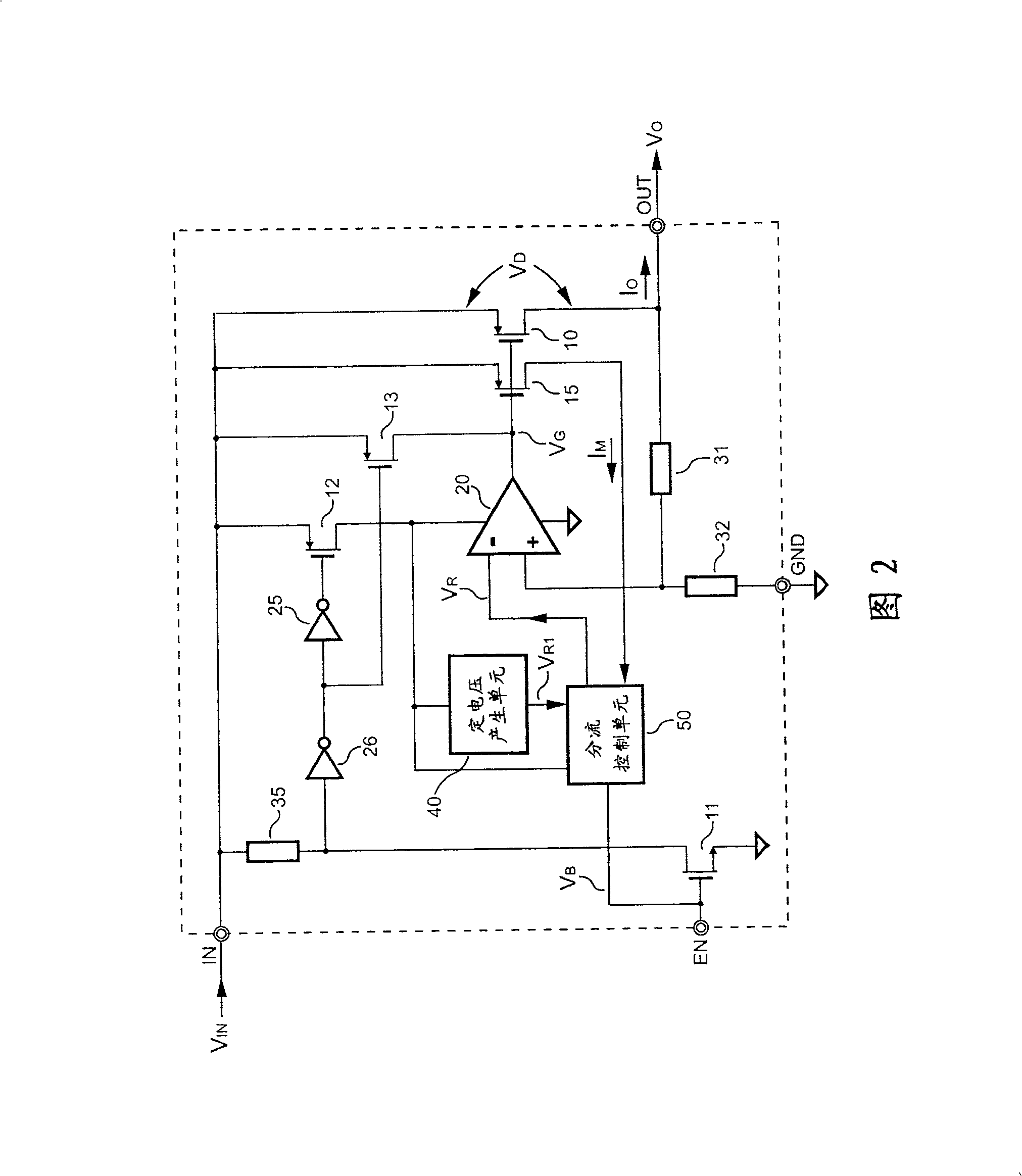

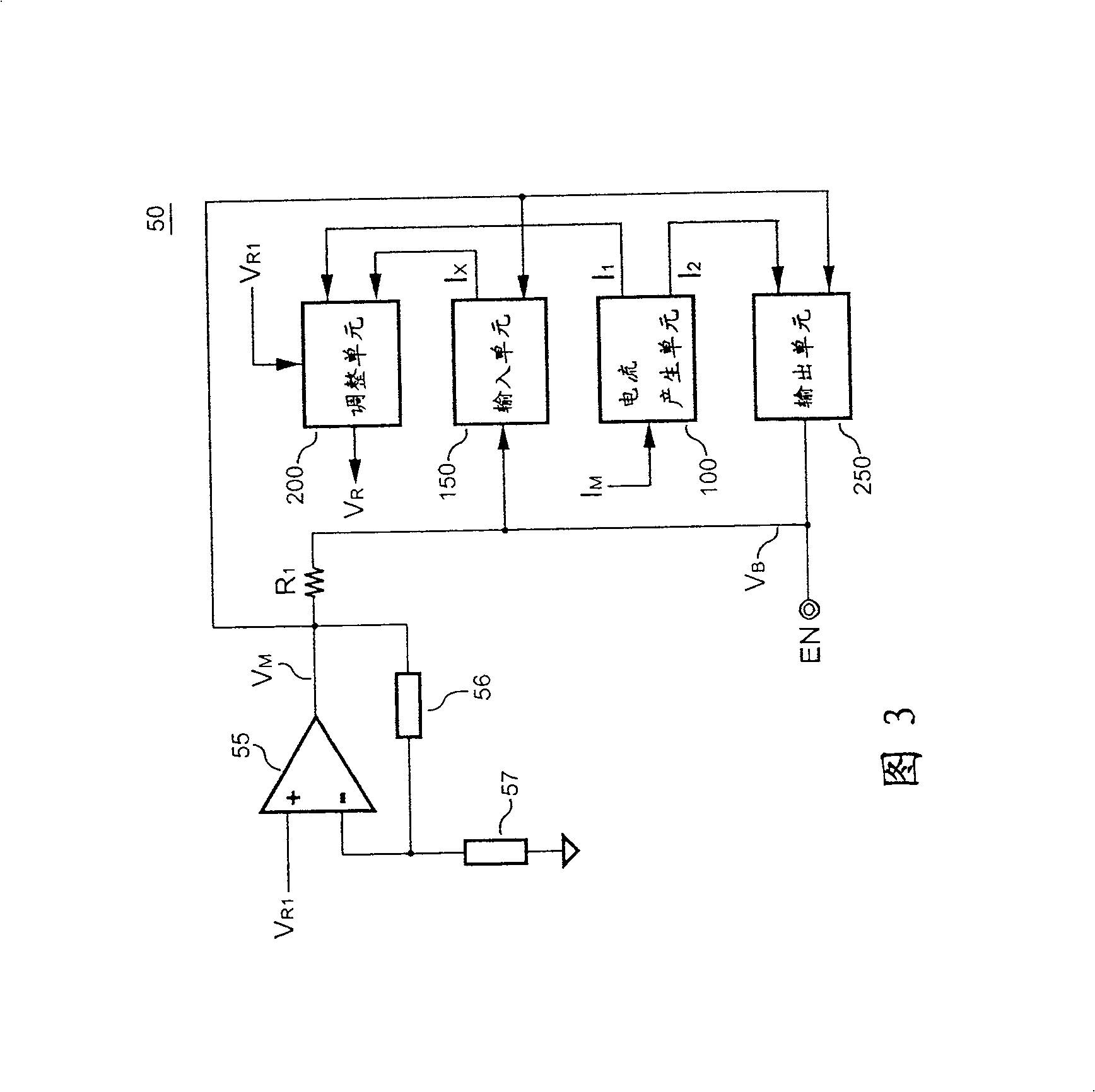

InactiveCN100421044CReduce output currentLower operating temperatureElectric variable regulationShunt DeviceEngineering

A distributary device is prepared as using distributary control end to provide distributary control interface and using series - connected electric crystal to receive input end voltage, generating reference voltage by set voltage generation unit, coupling feedback circuit to distributary device and series - connected electric crystal for controlling output of distributary device and for outputting current detection signal, coupling distributary control unit to distributary device and feedback control circuit for generating bus bar signal and for generating reference signal according to reference voltage and bus bar signal as well as current detection signal.

Owner:SYST GEN

Smart city garage guiding system

ActiveCN113724502AImprove applicable environmentEasy to viewControlling traffic signalsArrangements for variable traffic instructionsSmart cityMechanical engineering

The invention belongs to the field of garage guiding, and discloses a smart city garage guiding system which comprises a guiding system terminal. The top of the guiding system terminal is provided with a mounting seat, and the guiding system terminal is provided with uniformly distributed LED indicator boards; and each LED indicator board comprises a movable board, an indicating ball is installed on the movable board, an adjusting mechanism is installed in the movable board, the adjusting mechanism is connected with the indicating ball, and an indicating lamp is installed on the movable board. According to the invention, the indication direction of the indicating ball is controlled, passing vehicles and personnel can check the guiding indication signal more clearly and conveniently, the guiding system terminal enables the indicating ball to cooperate with the indicating lamp to provide guiding information, the indicating ball can be adjusted according to the actual installation condition, and the application environment of the garage guiding system is improved. Construction of a smart city is propelled, and compared with a traditional mode of firstly measuring and then installing, by using the system of the invention, the installation difficulty is greatly reduced.

Owner:姚元林

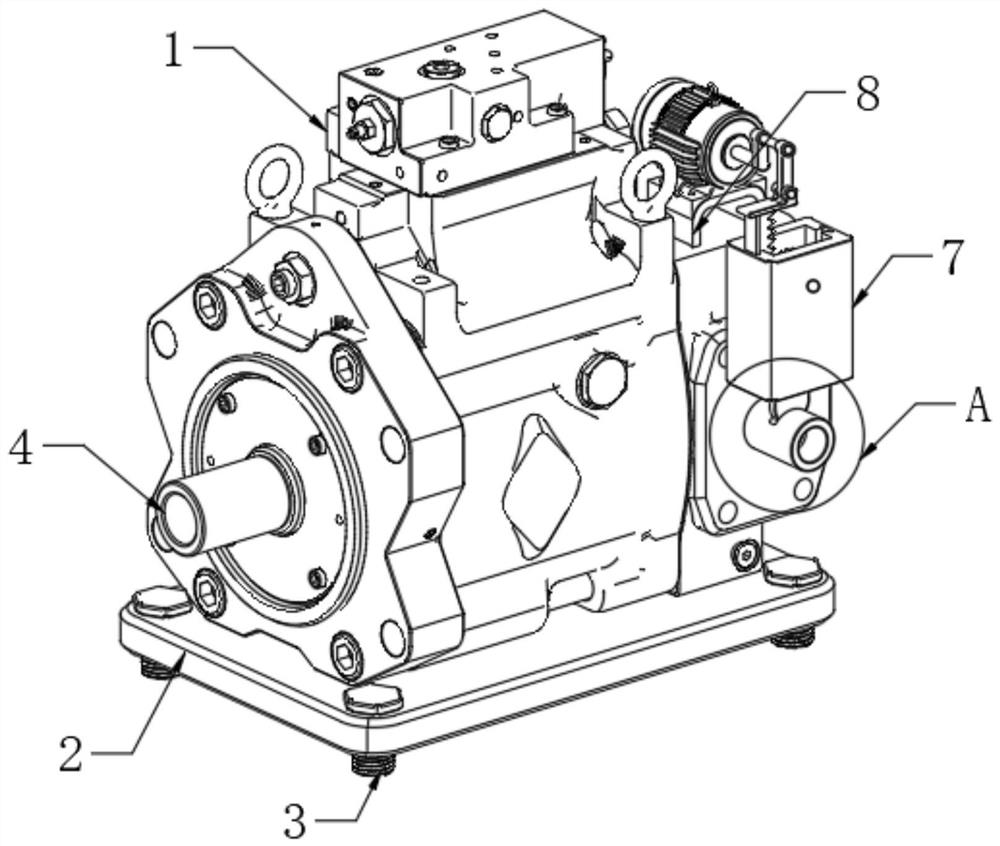

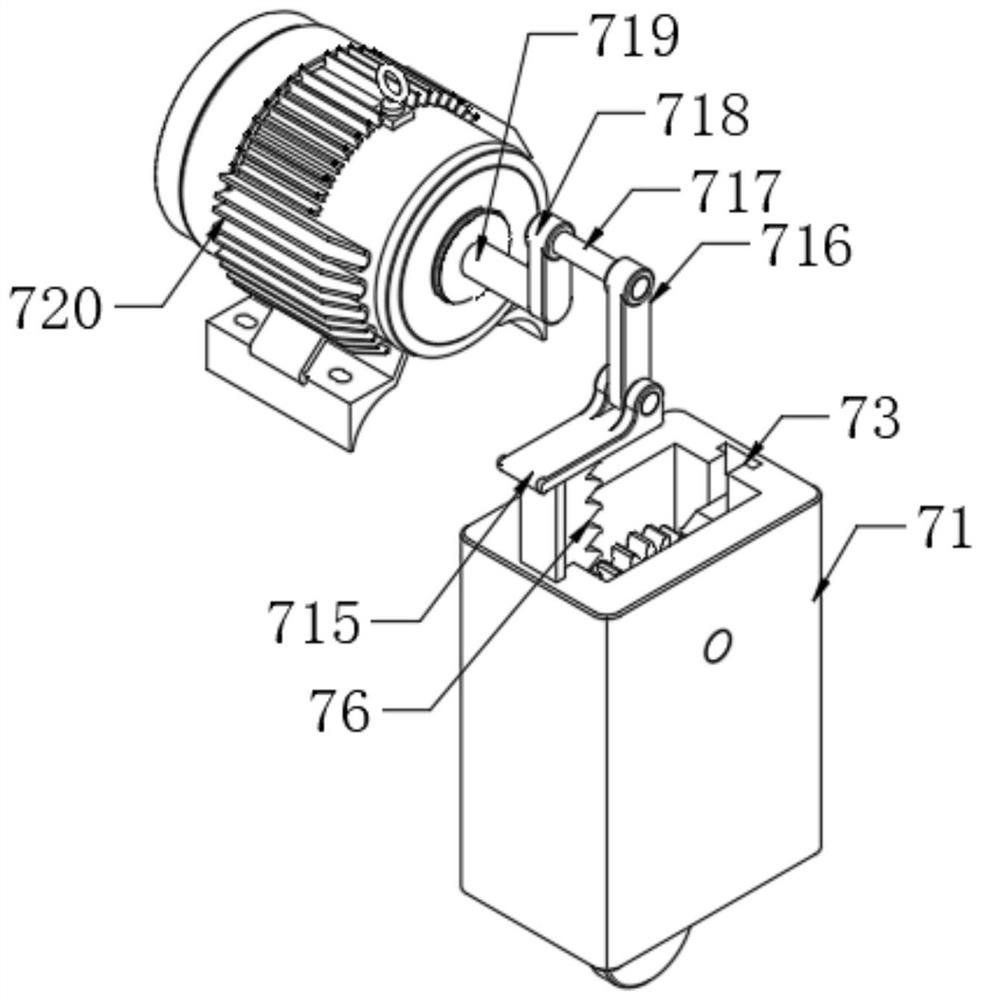

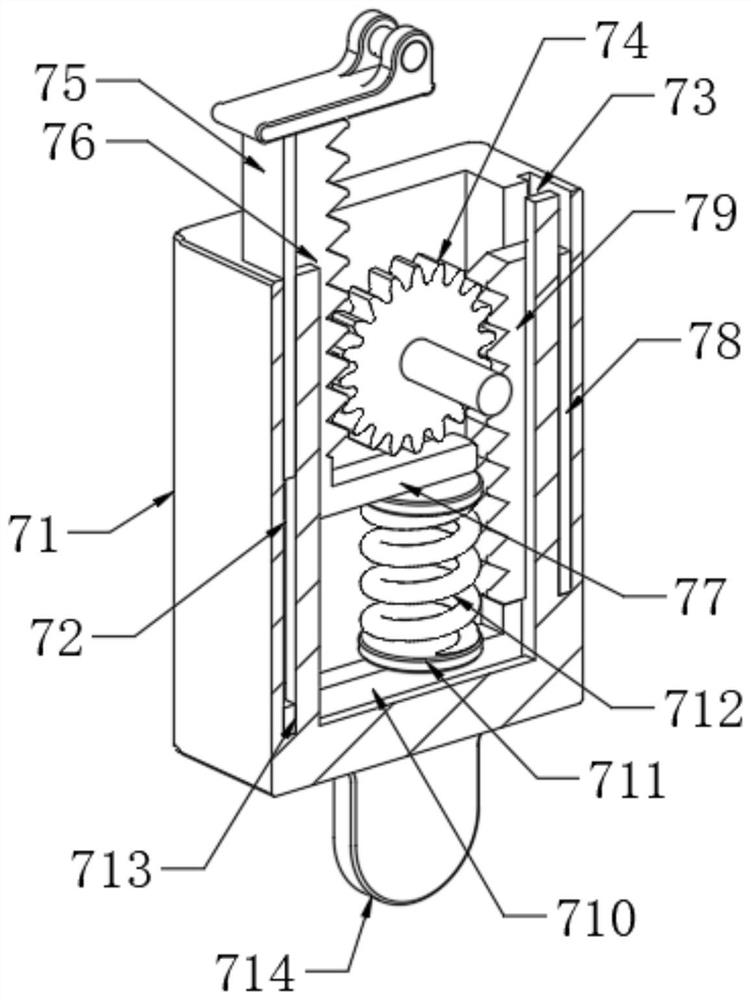

Automobile high-pressure oil pump with flow dividing and energy saving effects

PendingCN113958480AEasy to installEasy to usePositive displacement pump componentsPumpsElectric machineryControl engineering

The invention discloses an automobile high-pressure oil pump with flow dividing and energy saving effects. The automobile high-pressure oil pump comprises a high-pressure oil pump body, a control mechanism is arranged at the front end of the high-pressure oil pump body and comprises a control box fixedly arranged at the front end of the high-pressure oil pump body, and a control groove is formed in the inner wall of the control box; a moving groove is formed in the side, close to the control groove, of the inner wall of the control box, a gear shaft is movably arranged on the inner side of the control box through a rotating shaft, and a clamping block is slidably arranged on the inner side of the control groove. According to the automobile high-pressure oil pump with the flow dividing and energy saving effects, a motor is started to enable a connecting frame to drive a first gear plate to move, so that a gear shaft drives a second gear plate to move, a control rod drives a moving plate to move, the flow dividing purpose can be achieved, and therefore the flow dividing and energy saving effects are achieved.

Owner:NINGBO ANCHUANG ELECTRONICS TECH CO LTD

An aluminum casing shunt device

ActiveCN106144442BTo achieve the purpose of diversionReasonable designControl devices for conveyorsPackagingShunt DeviceEngineering

The invention provides an aluminum shell distributing device. A feeding conveyer belt is arranged on the back side of a rotating disk and is tangent to the rotating disk. A first discharging conveyer belt is installed on the left side of the rotating disk and is tangent to the rotating disk. A rotating plate and a rotating plate air cylinder are installed between the feeding conveyer belt and the first discharging conveyer belt. A second discharging conveyer belt is installed on the front side of the rotating disk and is tangent to the rotating disk. An adjusting plate is installed on the left side of the rotating disk. During normal transition, aluminum shells are conveyed by the feeding conveyer belt and reach an inlet of the rotating disk, the aluminum shells reach a first discharging position along with conveyance of the rotating disk, and then the aluminum shells enter a following machining device. During distribution, the machining speed of the following machining device is low and accumulation is generated, a photoelectric detector I sends a signal to enable the rotating plate to be ejected, and the aluminum shells behind the rotating plate reach a second discharging position through turning of a swing arm to enter the following machining device. When the following machining device goes wrong, a photoelectric detector II sends a signal to enable a swing arm air cylinder to drive the swing arm to rotate, and redundant aluminum shells are accumulated at the rotating disk. The aluminum shell distributing device can have certain distributing and aluminum shell storing functions.

Owner:舟山市新龙电子设备有限公司

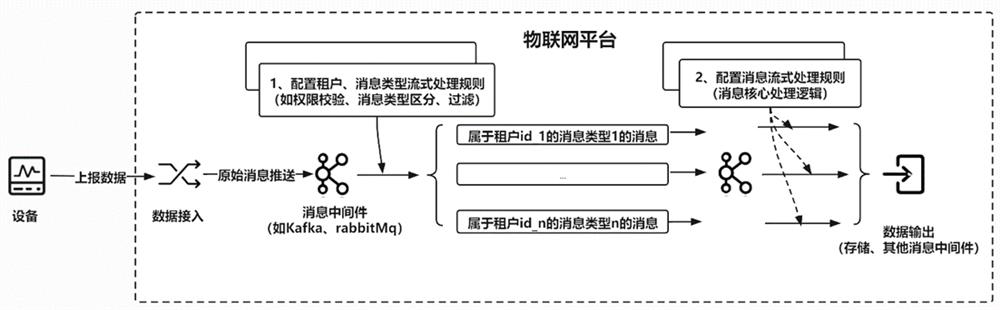

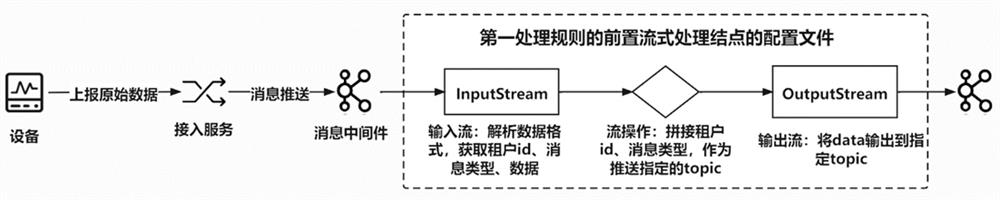

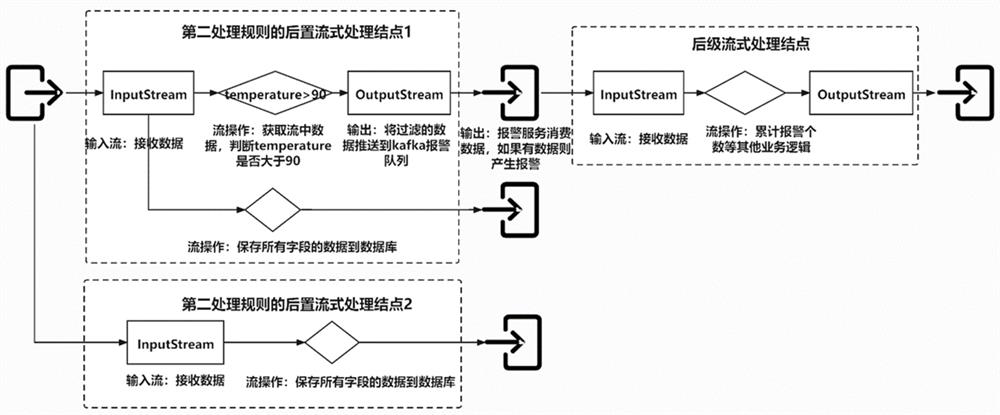

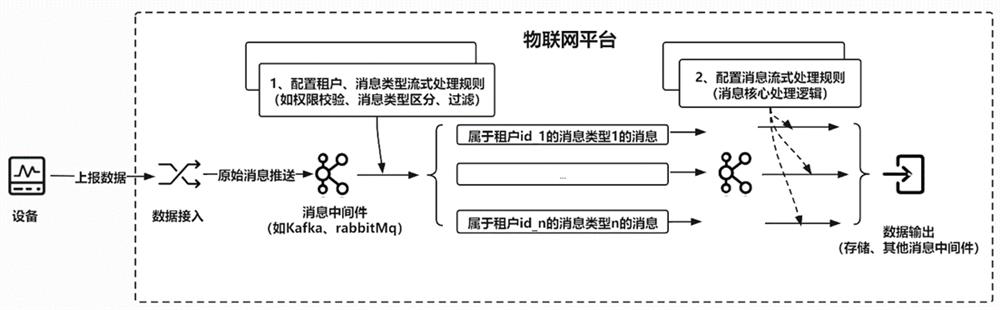

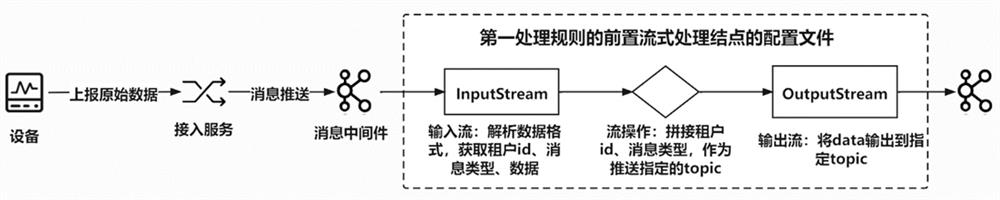

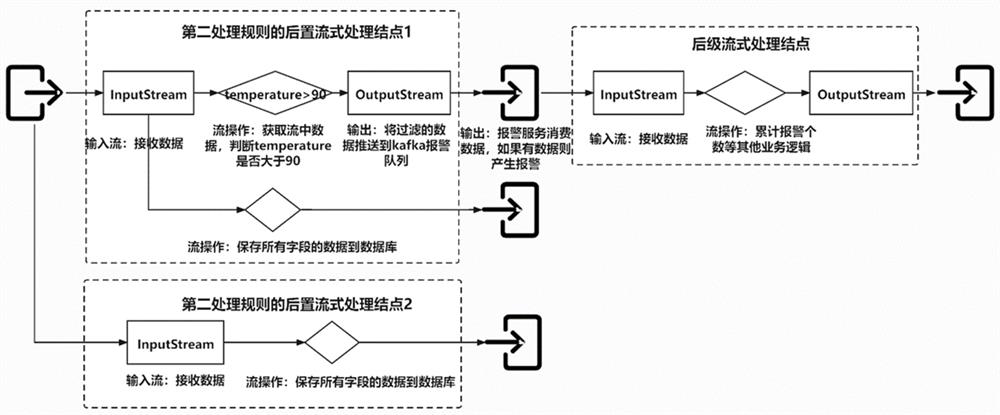

Internet of Things platform message processing method and system based on streaming processing

ActiveCN113821361ASmall footprintImprove scalabilityDigital data information retrievalInterprogram communicationOriginal dataThe Internet

The invention provides an Internet of Things platform message processing method based on streaming processing, which comprises the following steps: by an Internet of Things platform data access service, receiving data reported by equipment, and pushing original data reported by the equipment to message-oriented middleware for storing messages; setting a pre-streaming processing node configured with a first type of processing rule, splitting the original data stored in the message-oriented middleware into message branches taking specified feature information as a division basis, and then storing each message branch in the message-oriented middleware again; setting a post-stream processing node configured with a second type of processing rules, processing each message branch in the message middleware, and storing a processed result in a database or transferring the processed result to the next message middleware; and repeating the process until the processed data meets a preset service requirement. According to the method provided by the invention, the efficiency and the real-time performance of the Internet of Things platform for processing the message are improved, and meanwhile, the user can be supported to configure the streaming processing rule according to the service.

Owner:中节能晶和智慧城市科技(浙江)有限公司 +1

A cavity-splitting exhaust pipe assembly and engine

ActiveCN107965380BImprove compactnessTo achieve the purpose of cavityInternal combustion piston enginesExhaust apparatusExhaust fumesEngineering

The invention relates to the technical field of engines, and in particular to a split-cavity and split-flow exhaust pipe assembly and an engine. The exhaust pipe assembly is provided with an exhaust gas cavity, an exhaust port communicating with the exhaust gas cavity, and at least two intake air. The exhaust port is located at one end of the exhaust pipe assembly, and also includes a water inlet, a water inlet chamber A, a water inlet chamber B, a water return chamber and a drain that are arranged on the sub-chamber split-flow exhaust pipe assembly. The number of water inlets is the same as the number of air inlets; the water inlet chamber A is connected to a part of the water inlet; the water inlet chamber B is connected to another part of the water inlet; One end of the formed exhaust port is connected; the drain port is located at the other end of the exhaust pipe assembly; the water inlet cavity A and the return water cavity are both communicated with the drain port; the engine includes the above-mentioned sub-chamber and split-flow exhaust pipe assembly. The cavity-split flow exhaust pipe assembly provided by the invention has the functions of realizing cavity division and flow division, so that the design of the exhaust pipe assembly is more compact and beautiful.

Owner:WEICHAI POWER CO LTD

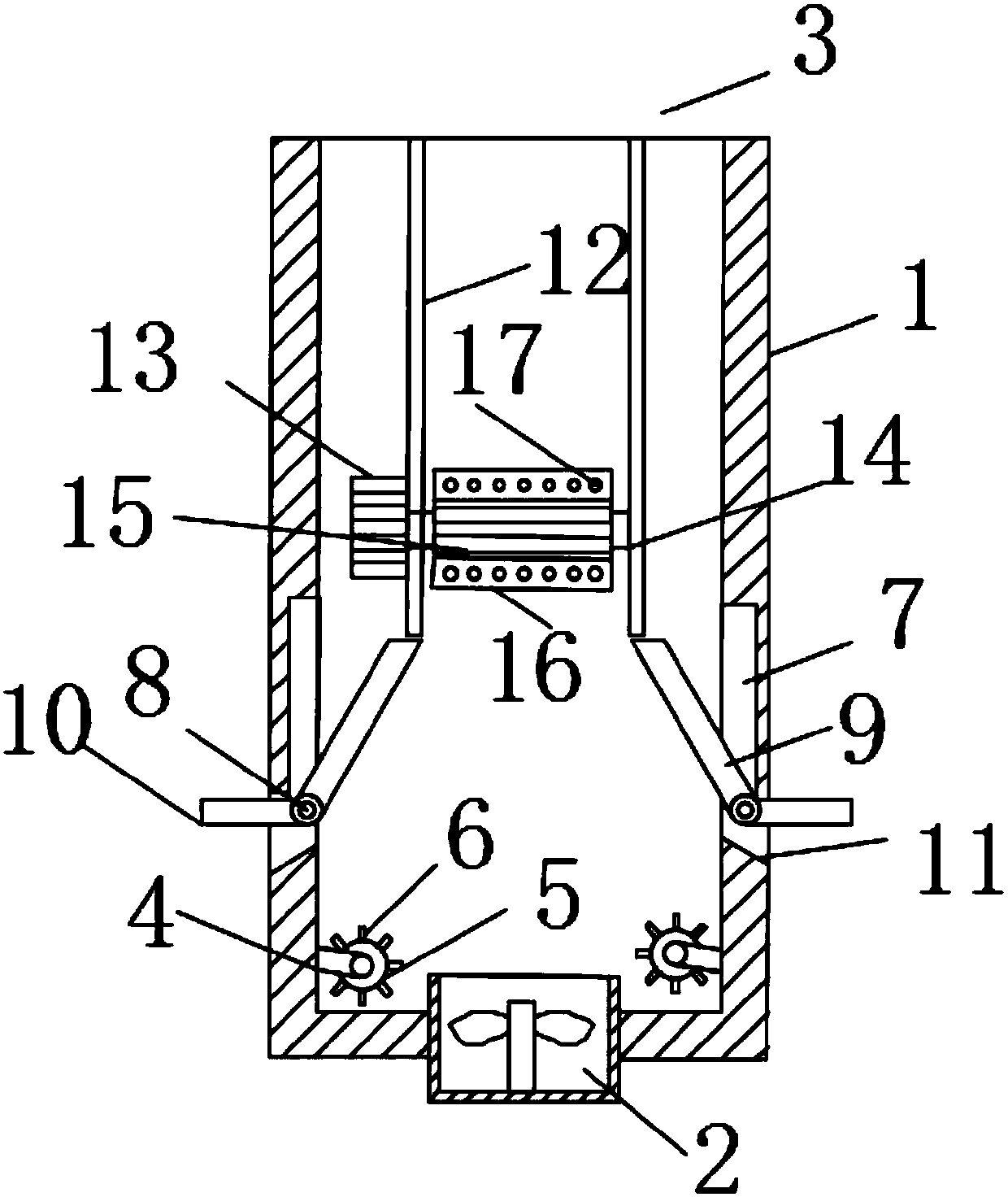

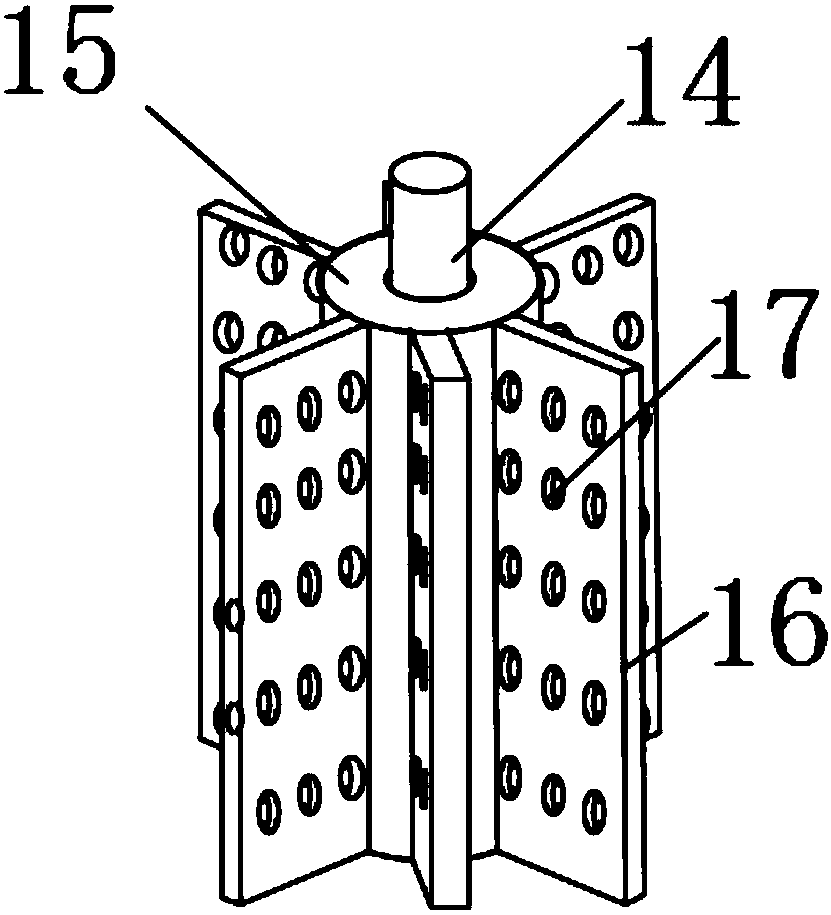

Distributing adjusting mechanism for heat treatment furnace

The invention relates to a distributing adjusting mechanism for a heat treatment furnace. The distributing adjusting mechanism comprises a distributing mechanism arranged in the heat treatment furnace and between a conveying belt and a discharging port, and a plurality of collecting devices located at the discharging port of the heat treatment furnace. The distributing device can be a rotating type distributing device or a horizontal-moving distributing device. According to the distributing adjusting mechanism for the heat treatment furnace, articles on which heat treatment is completed are distributed to the collecting devices, and therefore the articles on which heat treatment is completed are indeed distributed, and the heat treatment effect of the articles cannot be affected.

Owner:重盈阳成工业股份有限公司

Stabilizator and power supply with shunt control

ActiveCN100416441CReduce output currentLower operating temperatureElectric variable regulationControl signalVoltage reference

Owner:SYST GEN

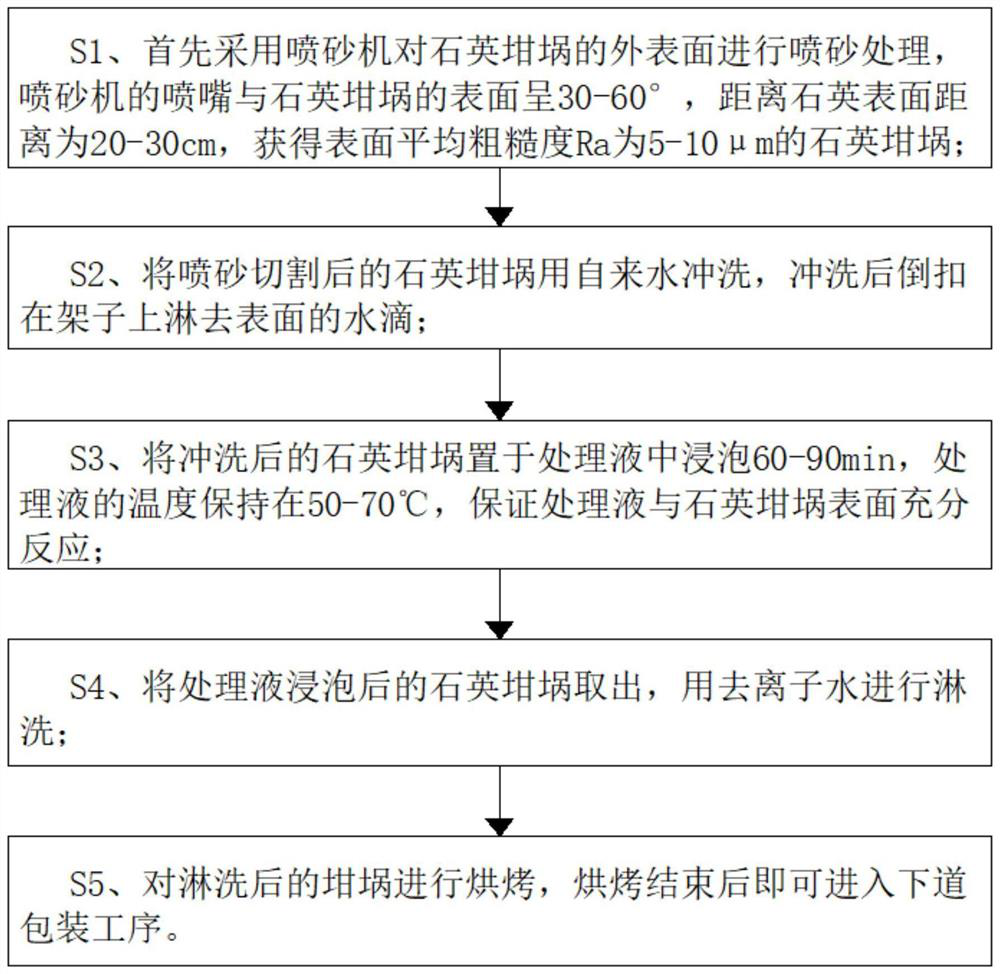

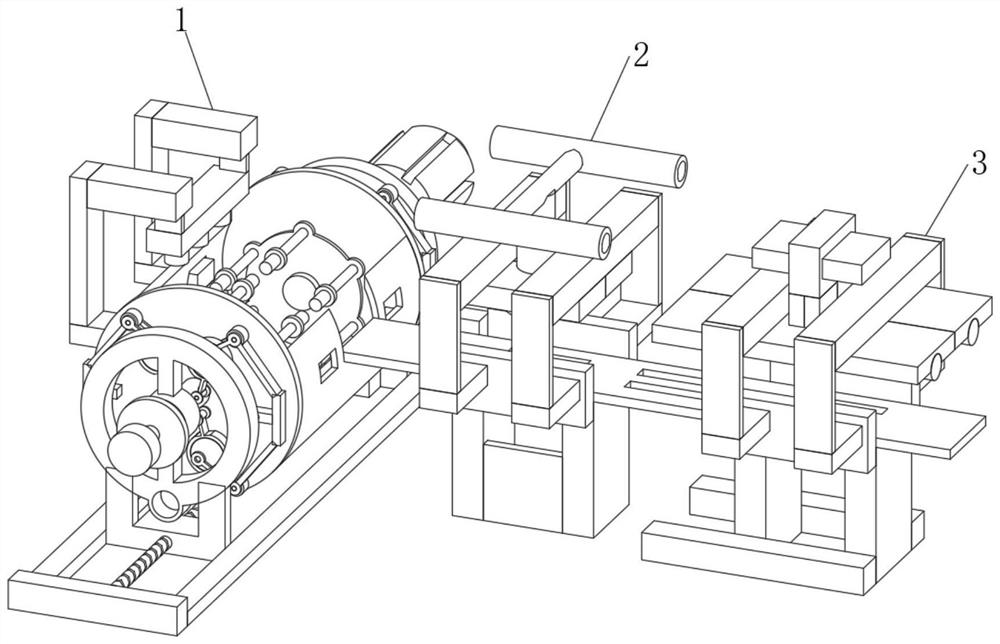

Surface treatment process and processing equipment for quartz crucible

The invention relates to the technical field of quartz crucible production equipment, in particular to a surface treatment process and processing equipment for a quartz crucible, and the process comprises the following steps: carrying out sand blasting treatment on the outer surface of the quartz crucible by adopting a sand blasting machine; washing the quartz crucible subjected to sand blasting cutting with tap water, and reversely covering the washed quartz crucible on a frame to spray water drops on the surface; the washed quartz crucible is placed in a treating fluid to be soaked; taking out the quartz crucible soaked in the treating fluid, and leaching with deionized water; the washed crucible is baked, and the next packaging procedure can be carried out after baking is finished; comprising a soaking production structure, a spraying structure and a heating production part. According to the surface treatment process disclosed by the invention, the quartz crucible has the surface with uniform roughness, no sand blasting, no peak and no crack; and the processing equipment can perform assembly line type processing production, so that the production efficiency of an enterprise is greatly improved.

Owner:连云港福典石英科技有限公司

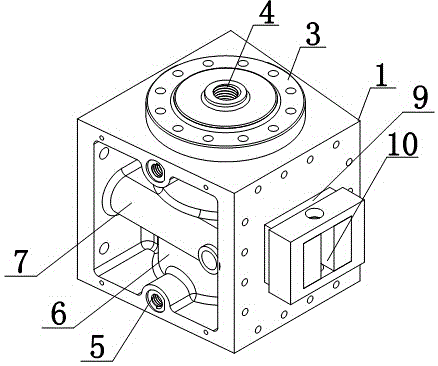

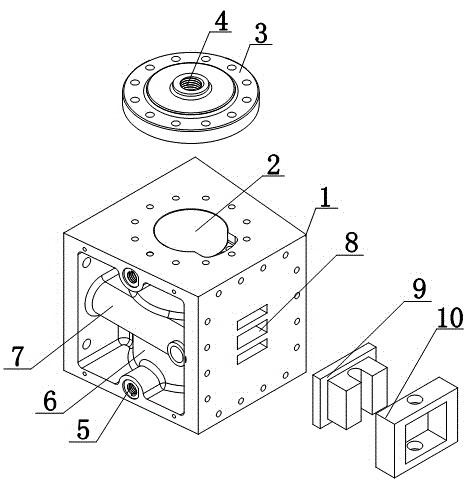

Radiator for collecting waste heat energy of air compressor and collecting method thereof

PendingCN109113967AMeet and achieve recyclingAchieve recyclingPositive displacement pump componentsPositive-displacement liquid enginesGas compressorProcess engineering

The invention relates to a radiator for collecting waste heat energy of an air compressor and a collecting method thereof, and the radiator includes a heat dissipation main board, a heat dissipation fan arranged on one side of the heat dissipation main board, a gas collecting assembly arranged on the other side of the heat dissipation main board and used for receiving hot gas, two rows of air inlet holes spaced apart on the top of the heat dissipation main board, converging frames covering the rows of air inlet holes and each provided with an air inlet and an air outlet, and a heat dissipationassembly arranged on the bottom of the heat dissipation main board and connected with each air inlet hole. The heat dissipation assembly comprises first heat dissipation tubes communicating with theair inlet holes and being in one-to-one correspondence, and a heat dissipation module rotatably communicates with each corresponding first heat dissipation tube. The heat dissipation module is gradually inclined and spaced from one side close to the gas collection assembly to the other side in a stepped shape. The invention has the beneficial effects of recovering waste heat energy generated whenthe air compressor is working and applying the waste heat energy to industrial production and manufacturing, and improving the utilization rate of resources.

Owner:QUZHOU CHUANTE ELECTRONICS TECH CO LTD

A method and system for message processing of Internet of Things platform based on stream processing

ActiveCN113821361BSmall footprintImprove scalabilityDigital data information retrievalInterprogram communicationOriginal dataThe Internet

Owner:中节能晶和智慧城市科技(浙江)有限公司 +1

Signal processing apparatus and method for setting filtering characteristic of the same

ActiveCN102195661BTo achieve the purpose of diversionSimple structureTransmissionComputer scienceSignal processing

The present invention provides a signal processing apparatus and a method for setting a filtering characteristic of the same. The method for setting the filtering characteristic of the signal processing apparatus comprises the following steps: configuring a first signal processing path; and configuring a second signal processing path. When an input signal received at the signal input port includes a first signal component with a first frequency and a second signal component with a second frequency, most of the first signal component is processed by the first signal processing path, and most of the second signal component is processed by the second signal processing path. The signal processing apparatus and the method for setting the filtering characteristic of the signal processing apparatus can effectively filter the unwanted signal component.

Owner:MEDIATEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com