Radiator for collecting waste heat energy of air compressor and collecting method thereof

A technology of heat energy collection and air compressor, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., and can solve the problems of unsatisfactory collection and inability to collect waste heat energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

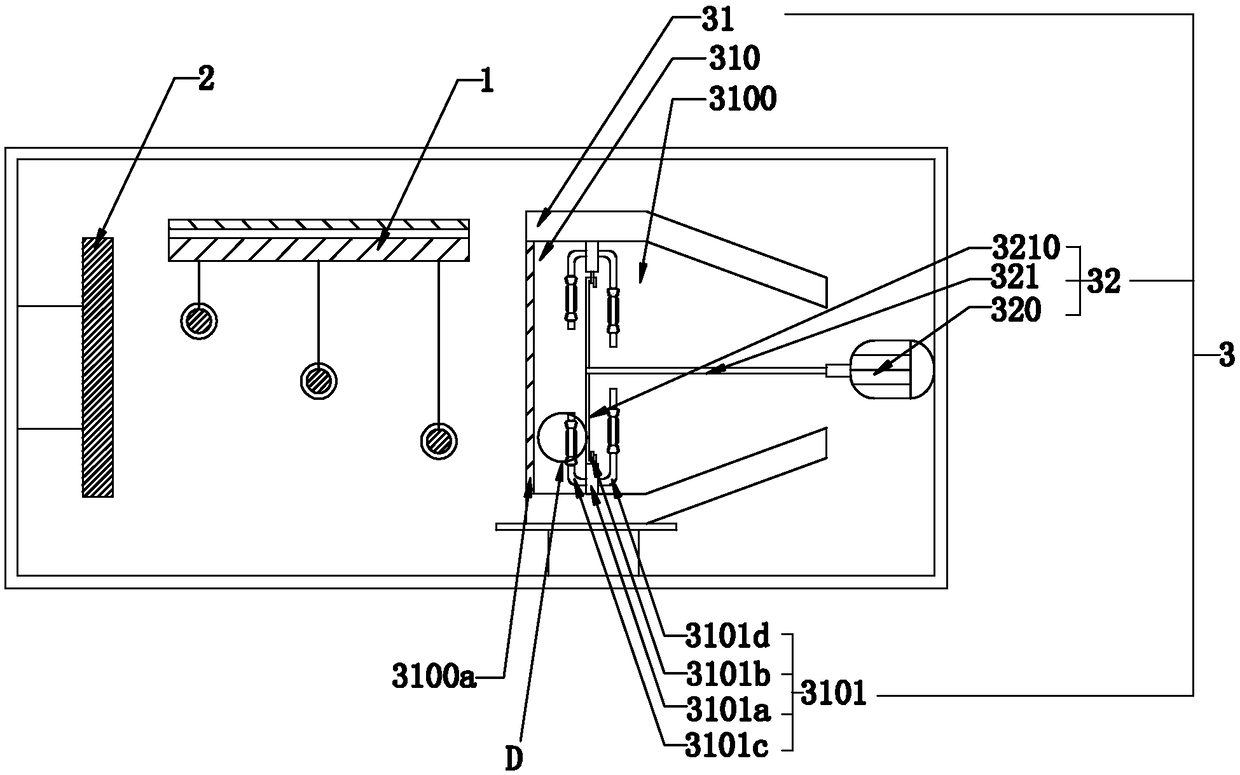

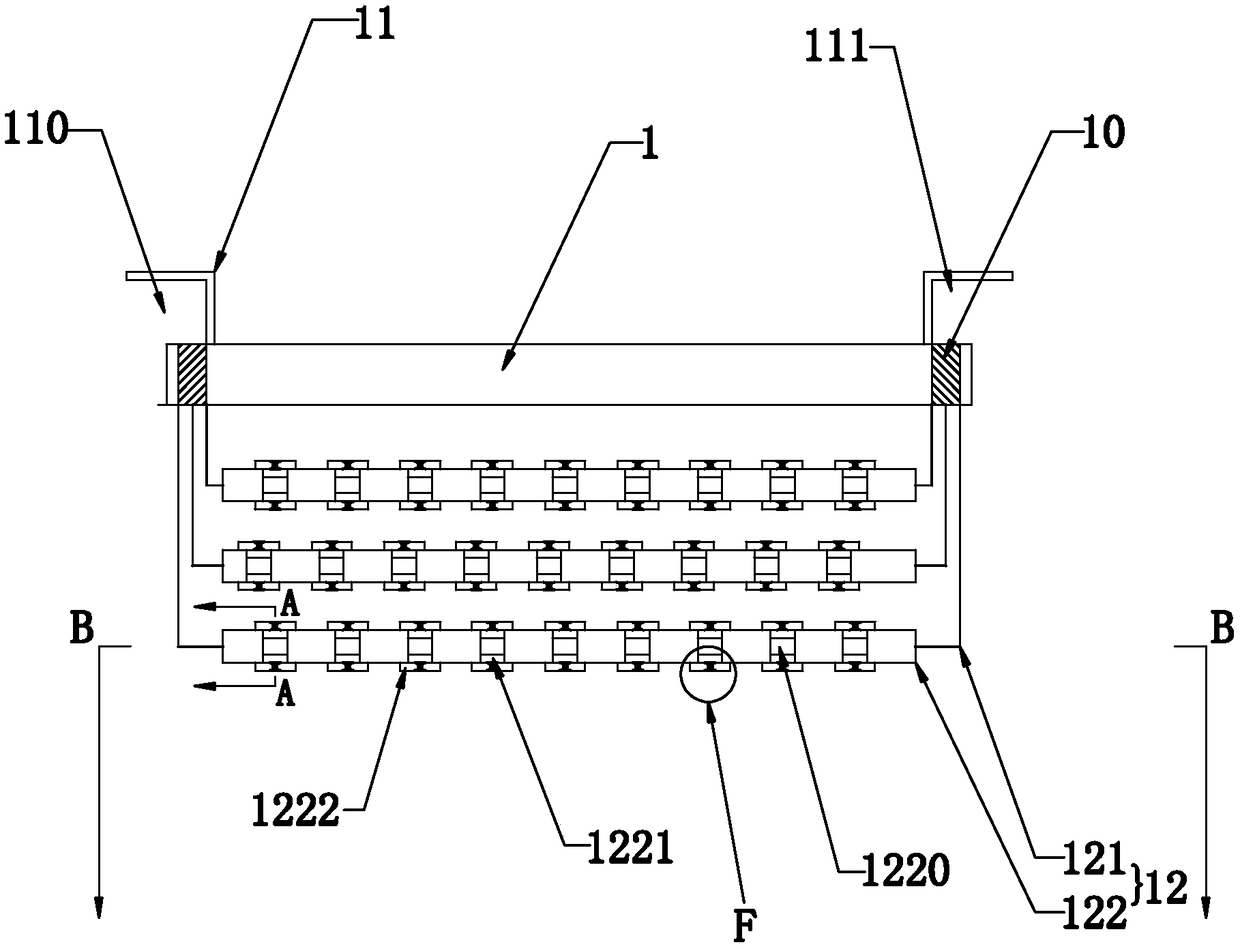

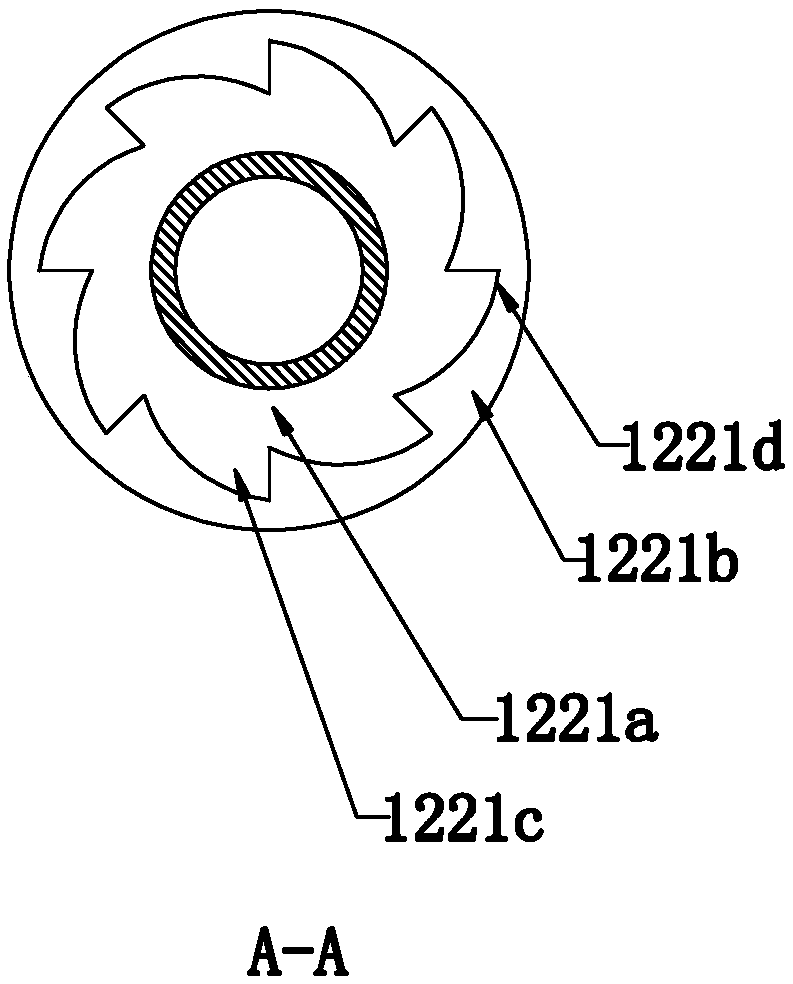

[0031] Such as Figure 1 to Figure 7 As shown, the present invention discloses a radiator for collecting waste heat energy of an air compressor. On the other side, the air collecting assembly 3 for receiving hot air, two rows of air inlets 10 arranged at intervals on the top of the heat dissipation main board 1, covering each row of air inlets 10 and having air inlets 110 and air outlets 111 respectively The converging frame 11 and the heat dissipation assembly 12 arranged at the bottom of the heat dissipation motherboard 1 and connected to each air intake hole 110; pipes 121, and between each corresponding first heat dissipation pipe 121, there is a heat dissipation module 122 in rotational communication. The outer wall of the heat dissipation module 122 is provided with several recesses 1220 at equal intervals in the axial direction, and in each recess 1220 passes through a one-way The rotating device 1221 axially rotates the connected heat dissipation air guide vane 1222, ...

Embodiment 2

[0040] A method for collecting waste heat energy of an air compressor, comprising the steps of:

[0041] S1: Pass the waste heat generated by the air compressor into the air intake hole set on the heat dissipation main board through the air inlet;

[0042]S2: The waste hot air entering the heat dissipation holes continues to pass through the heat dissipation components arranged between the heat dissipation holes, and the fan continues to dissipate the heat of the waste heat passing through the heat dissipation components and purify the internal heat;

[0043] S3: Collect and utilize the hot gas purified in S2 through the gas collection assembly;

[0044] S4: Exhaust the heat-dissipated waste heat in S2 through the air inlet provided at the air outlet of the heat-dissipating main board.

[0045] In a specific embodiment of the present invention, the hot waste gas discharged from S4 is used to keep the hot gas collected in S3 warm.

[0046] By adopting the above technical sche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com