Divided cavity and divided flow type exhaust pipe assembly and engine

An exhaust pipe and split flow technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problem that the structure of the water jacket exhaust pipe assembly is not compact and unsightly, and the structure of the water jacket exhaust pipe is not compact and unsightly and other issues to achieve the effect of improving compactness and efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

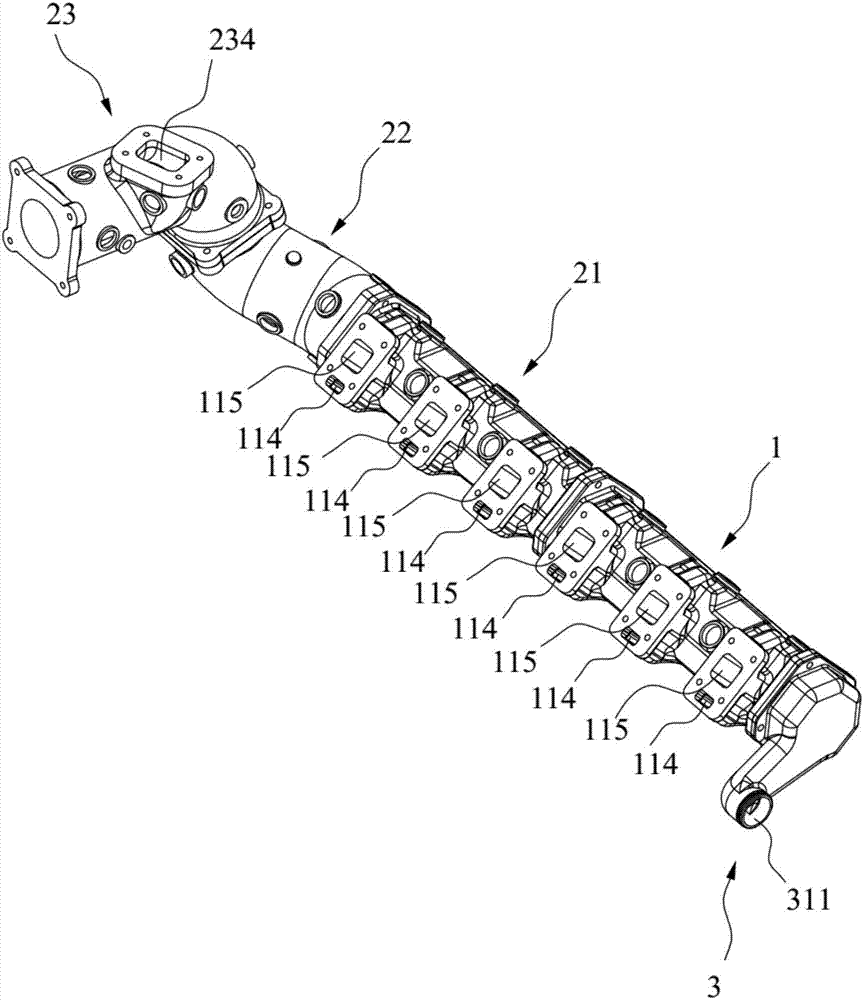

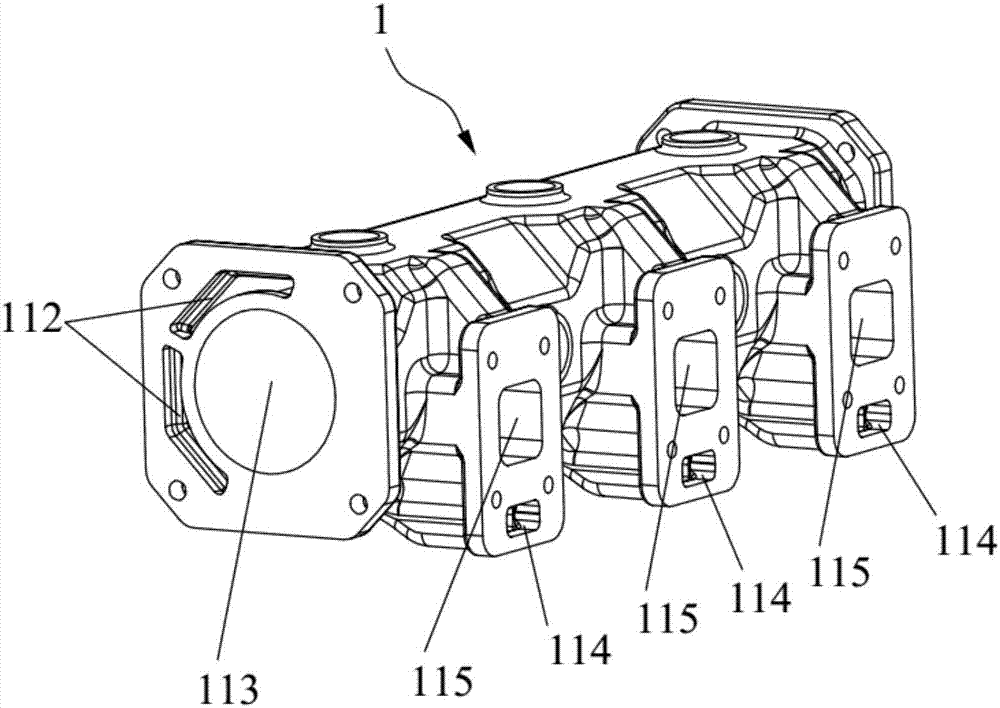

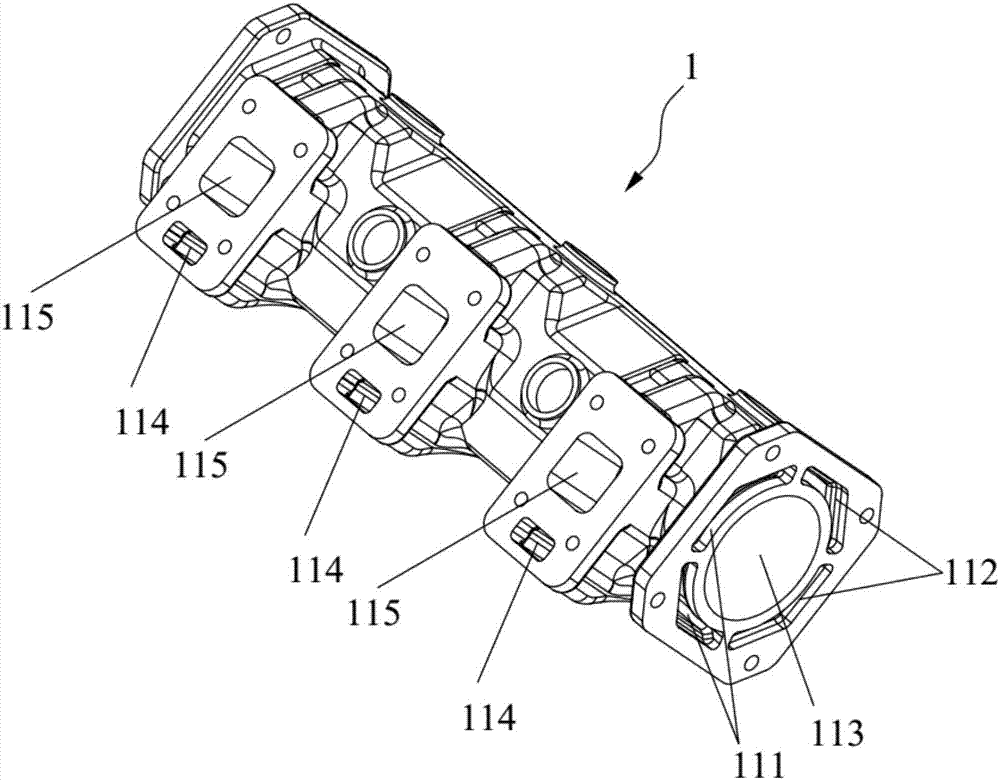

[0048] On the one hand, this embodiment provides a split-cavity split-flow exhaust pipe assembly, such as Figure 1-10 As shown, the exhaust pipe assembly is provided with exhaust chamber, air inlet 115, water inlet 114, water inlet chamber A111, water inlet chamber B, return water chamber, drain outlet 311 and exhaust outlet 234, wherein the inlet The number of air inlets 115 and water inlets 114 is equal, and there are at least two of them. Each air inlet 115 communicates with the waste gas chamber, part of the water inlet 114 communicates with the water inlet chamber A111, and the other part of the water inlet 114 communicates with the water inlet. The chamber B communicates, the exhaust port 234 and the drain port 311 are respectively arranged at both ends of the exhaust pipe assembly, the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com