An aluminum casing shunt device

A shunting device and aluminum casing technology, applied in the direction of conveyor control device, packaging, transportation and packaging, etc., can solve the problems of inability to realize automatic assembly line operation, aluminum casing scrapping, no automatic storage and automatic detection of the number of aluminum casings, etc., to achieve The effect of complete functions, low cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

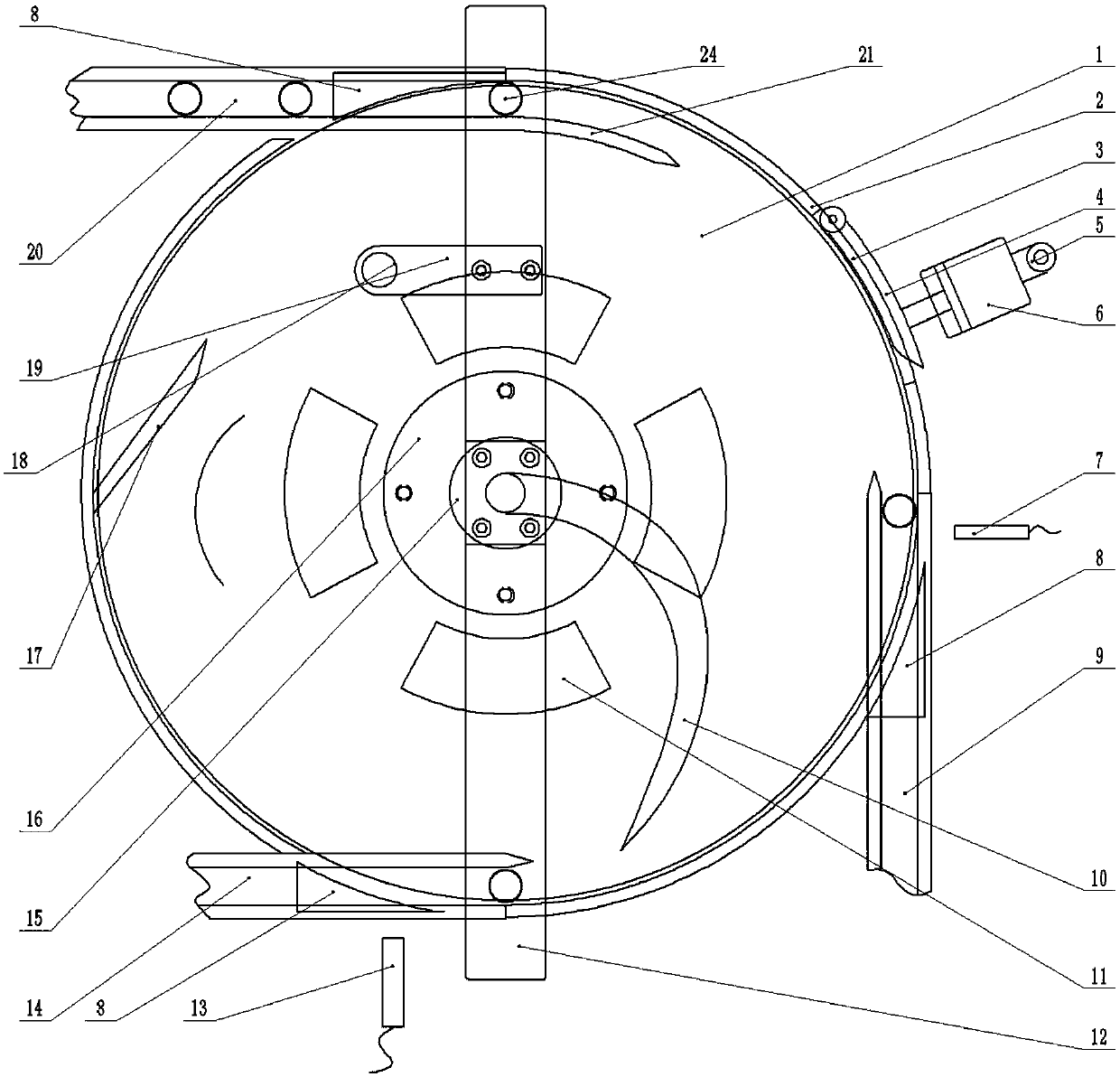

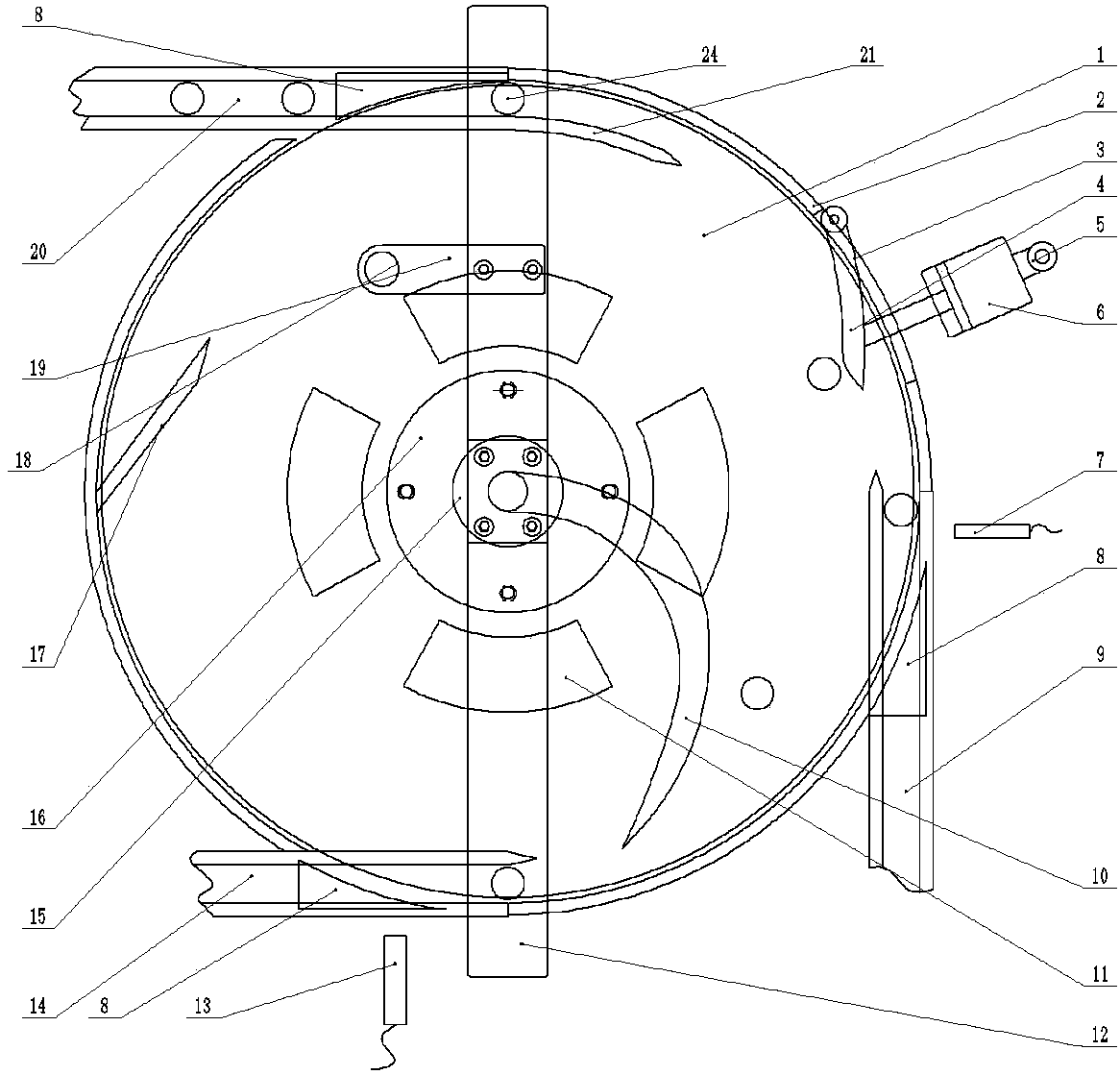

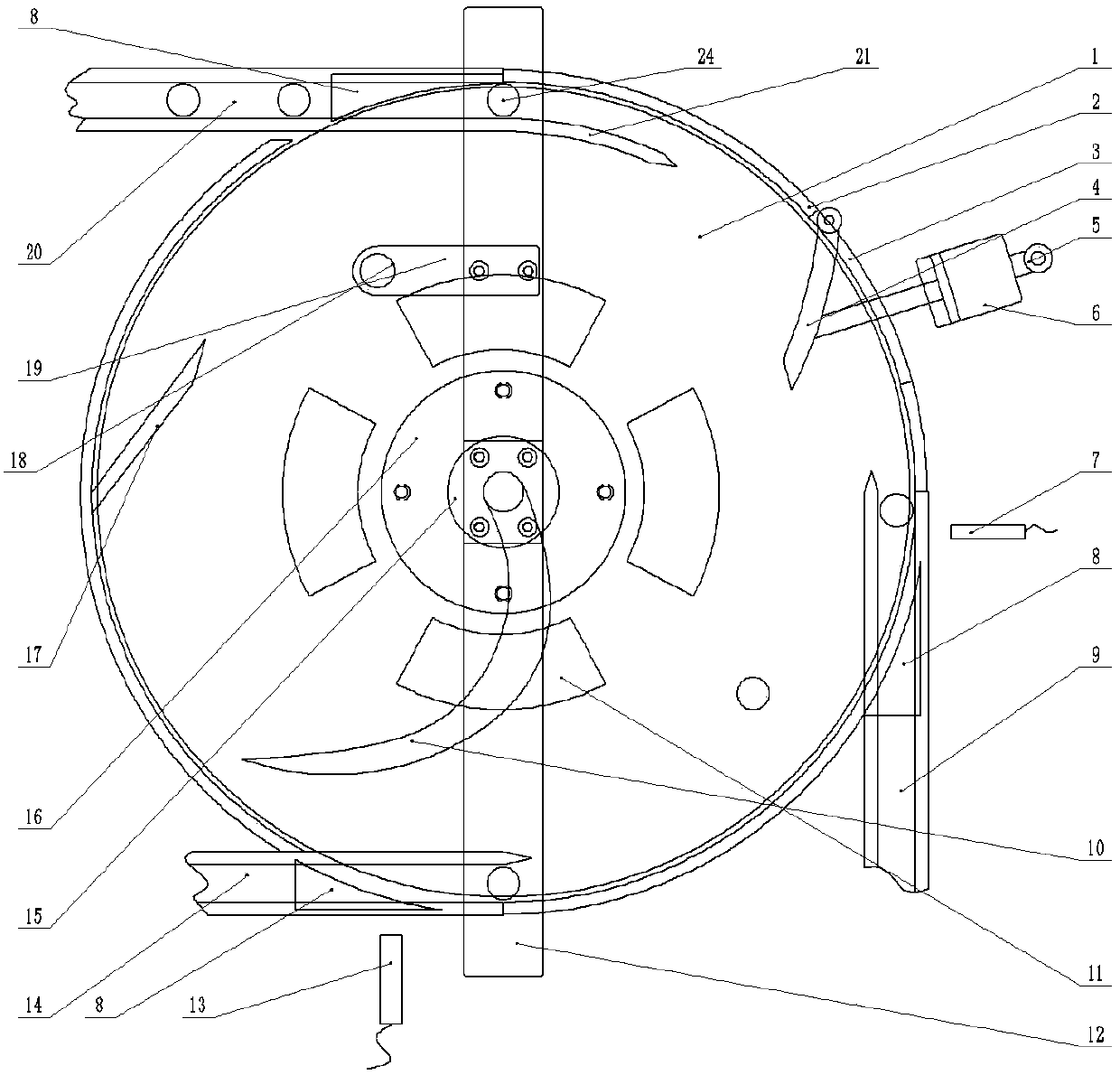

[0034] like Figure 1-4 As shown, an aluminum casing shunt device according to the embodiment of the present invention includes: the turntable 1 is connected to the motor 23 through the flange 16, and rotates clockwise with the motor; 2 Process the coaming plate hole 3 corresponding to the rotating plate 4, so that the swing arm can rotate in the coaming plate hole. The supporting plate 25 is installed under the turntable 1, which is used to install the coaming 2 and the cross bar 12; On the right side, tangent to the turntable 1, photoelectric detection I is installed on the side of the first discharge conveyor belt 9; the second discharge conveyor belt 14 is installed in front of the turntable 1, tangent to the turntable 1, and the second discharge conveyor belt 14 The photoelectric detection II 13 is installed on the side; transition plates 8 are installed at the contact points of the feed conveyor belt 20, the first discharge conveyor belt 9 and the second discharge conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com