Surface treatment process and processing equipment for quartz crucible

A quartz crucible and surface processing technology, applied in the field of surface treatment technology and processing equipment of quartz crucible, can solve problems such as inconvenience in processing and production, inconvenience in running smoothly, inconvenience in mixing and soaking reaction work, etc., and achieves the effect of improving efficiency and facilitating surface drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

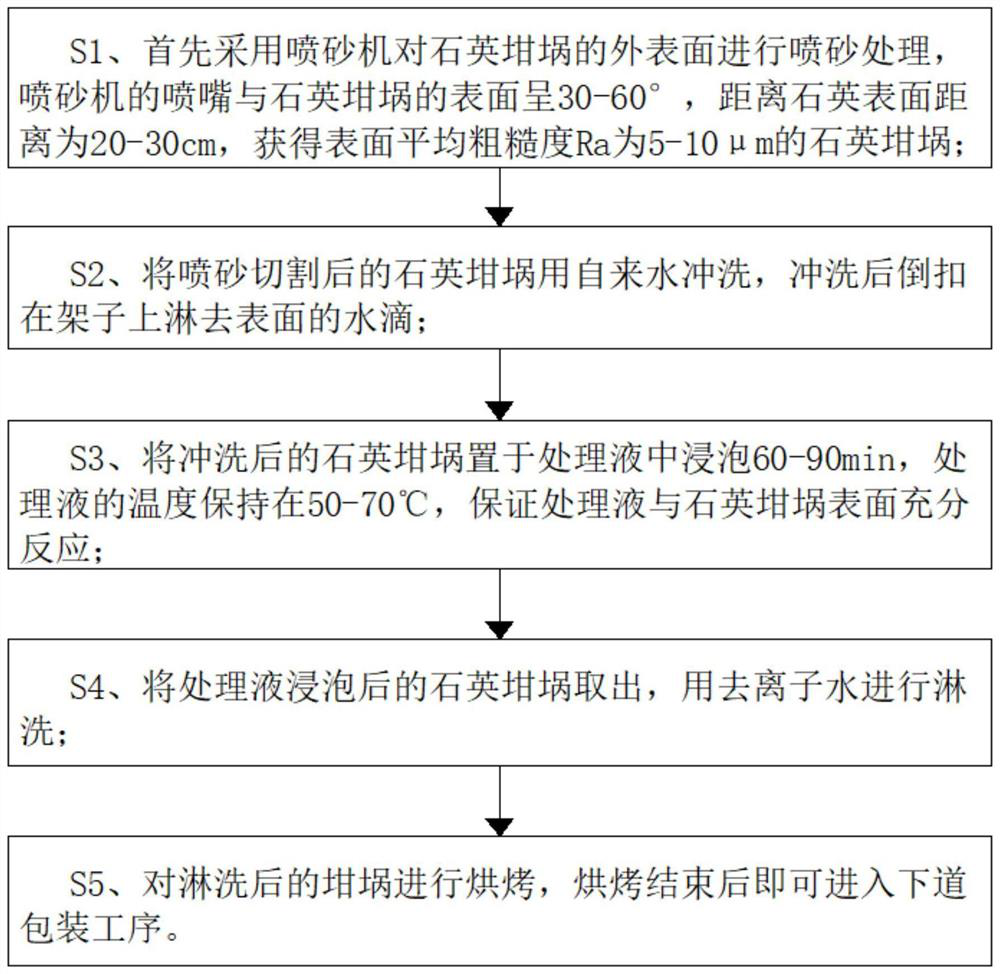

[0052] A kind of quartz crucible, its surface treatment process comprises the following steps:

[0053] S1. First, use a sandblasting machine to perform sandblasting on the outer surface of the quartz crucible. The nozzle of the sandblasting machine is 30° from the surface of the quartz crucible, and the distance from the quartz surface is 20 cm to obtain a quartz crucible with an average surface roughness Ra of 8 μm. ;

[0054] S2. Rinse the quartz crucible after sandblasting and cutting with tap water, and after rinsing, place it upside down on the shelf to drench off the water droplets on the surface;

[0055] S3. Place the washed quartz crucible in the treatment solution and soak for 60 minutes, and keep the temperature of the treatment solution at 35° C. to ensure that the treatment solution fully reacts with the surface of the quartz crucible;

[0056] S4, take out the quartz crucible soaked in the treatment solution, and rinse with deionized water;

[0057] S5. Baking...

Embodiment 2

[0060] A kind of quartz crucible, its surface treatment process comprises the following steps:

[0061] S1. First, use a sandblasting machine to perform sandblasting on the outer surface of the quartz crucible. The nozzle of the sandblasting machine is at 45° to the surface of the quartz crucible, and the distance from the quartz surface is 25 cm to obtain a quartz crucible with an average surface roughness Ra of 7 μm. ;

[0062] S2. Rinse the quartz crucible after sandblasting and cutting with tap water, and after rinsing, place it upside down on the shelf to drench off the water droplets on the surface;

[0063] S3. Soak the washed quartz crucible in the treatment solution for 60-90 minutes, and keep the temperature of the treatment solution at 40° C. to ensure that the treatment solution fully reacts with the surface of the quartz crucible;

[0064] S4, take out the quartz crucible soaked in the treatment solution, and rinse with deionized water;

[0065] S5. Baking the r...

Embodiment 3

[0068] A kind of quartz crucible, its surface treatment process comprises the following steps:

[0069] S1. First, use a sandblasting machine to perform sandblasting on the outer surface of the quartz crucible. The nozzle of the sandblasting machine is 60° from the surface of the quartz crucible, and the distance from the quartz surface is 30 cm to obtain a quartz crucible with an average surface roughness Ra of 10 μm. ;

[0070] S2. Rinse the quartz crucible after sandblasting and cutting with tap water, and after rinsing, place it upside down on the shelf to drench off the water droplets on the surface;

[0071] S3. Soak the washed quartz crucible in the treatment solution for 90 minutes, and keep the temperature of the treatment solution at 50° C. to ensure that the treatment solution fully reacts with the surface of the quartz crucible;

[0072] S4, take out the quartz crucible soaked in the treatment solution, and rinse with deionized water;

[0073] S5. Baking the rins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com