Table concentrator flow guide control system based on visual servo and table concentrator flow guide control method

A technology of diversion control and visual servoing, which is applied in the field of shaking table diversion control system based on visual servoing, can solve the problems such as the influence of technical proficiency and professional quality of mineral processing accuracy, the need to improve the automation level, and the difficulty of improving mineral processing accuracy. To achieve the effect of long-term operation accuracy and guarantee, improve mineral processing efficiency and accuracy, and improve the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

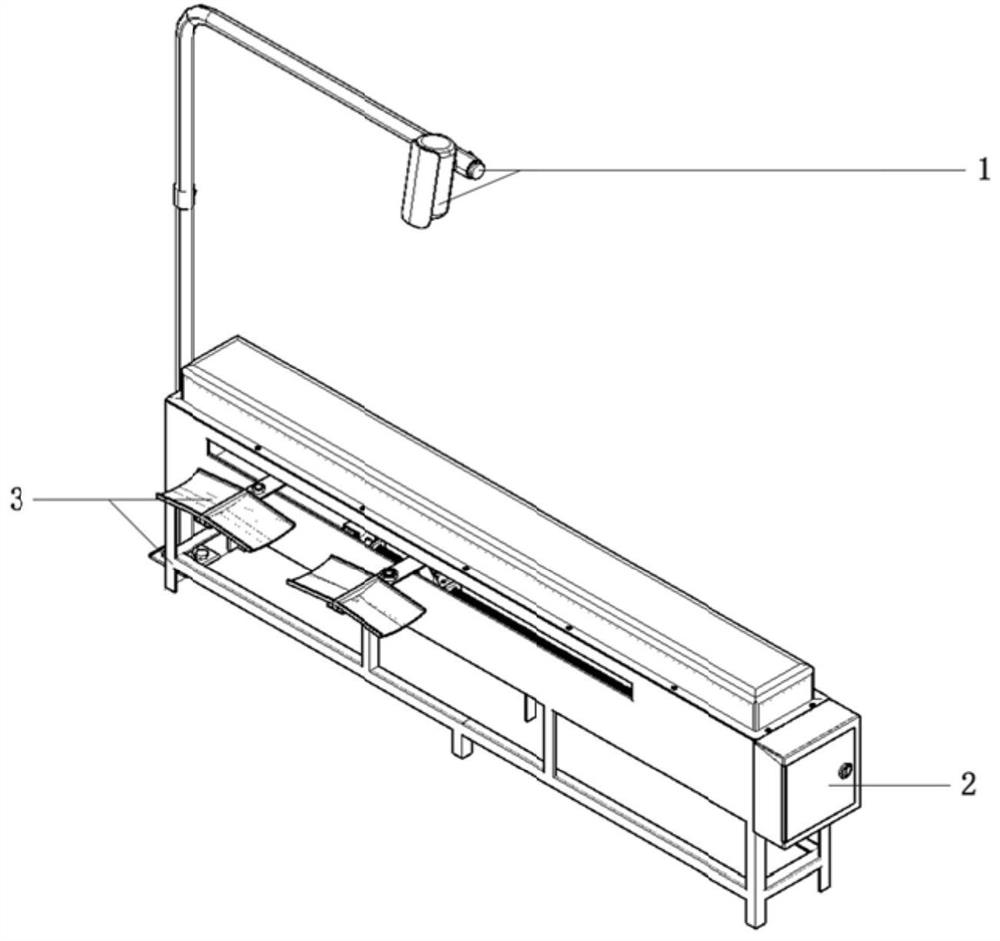

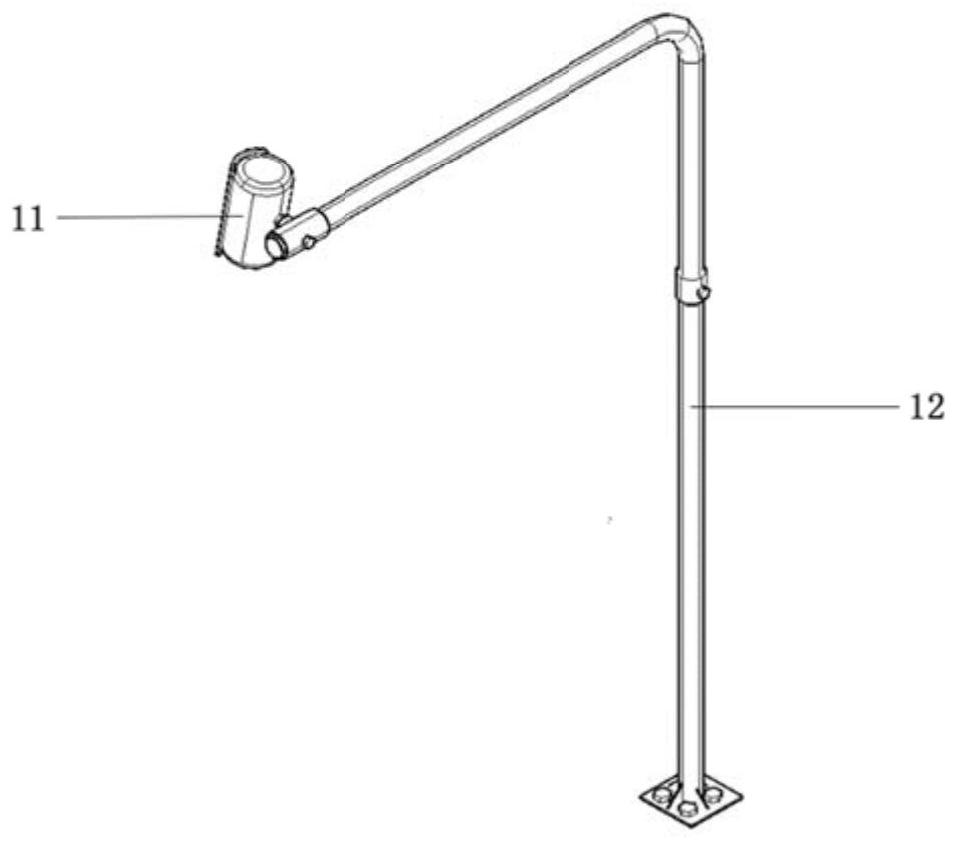

[0057] Such as figure 1 As shown, a shaker diversion control system based on visual servoing includes a visual acquisition unit 1 for collecting real-time images, an operation control unit 2 for control, and a servo diversion mechanism for diversion of the shaker device 3.

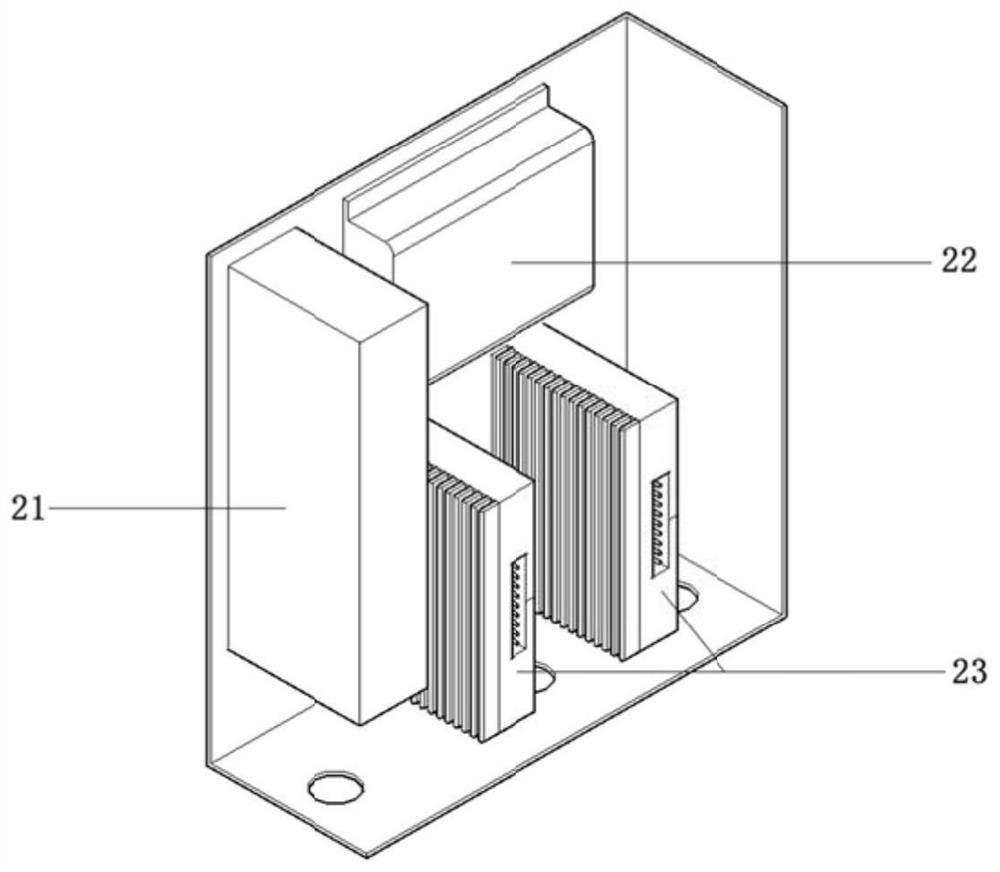

[0058] Such as Figure 4 As shown, the servo deflector mechanical device 3 includes a deflector housing 31, a servo slide group 32, a positioning mark 33, and a deflector baffle 34. The deflector housing 31 is made of stainless steel, and its exterior is coated with antirust paint. The structure is compact, and the deflector housing 31 is used to install and protect other components of the servo deflector mechanical device 3; On the slide group 32 and can move on the servo slide group 32, the guide baffle 34 is provided with a positioning mark 33 for determining the position coor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com