Bundled pipe wellhead multi-channel flow dividing device

A diverter device and tube bundle technology, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of large pressure system difference, large floor area, high production cost, etc., to ensure the accuracy of docking and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that the embodiments in this application and the features in the embodiments can be combined with each other without conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and examples.

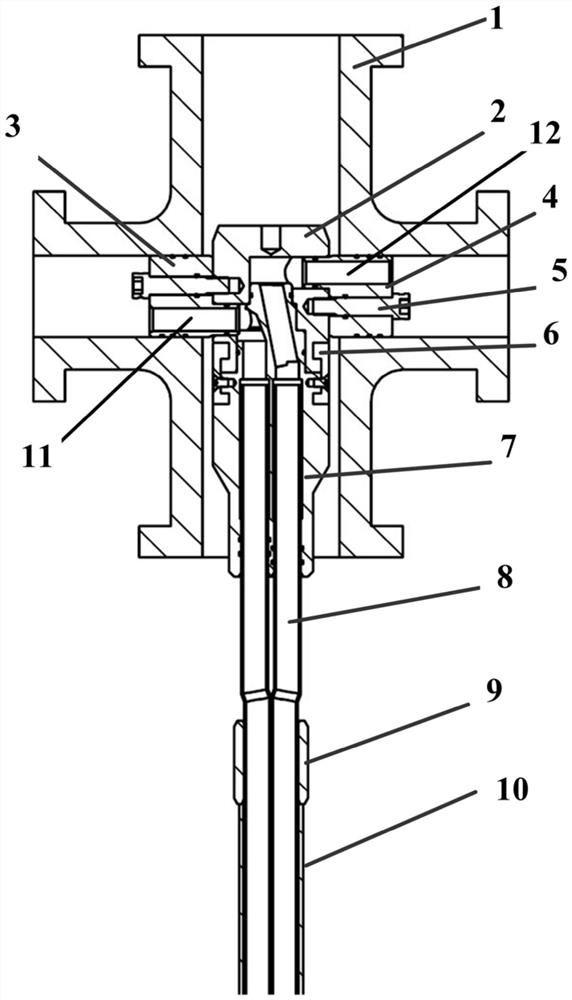

[0019] such as Figure 1 As shown in the figure, the embodiment of the invention provides a multi-channel shunt device for a cluster pipe wellhead, which comprises an external cross 1, a connector assembly, a left connector 3 and a right connector 4. The external four-way connector 1 comprises an upper interface, a lower interface, a left interface and a right interface which are communicated with each other, the upper interface and the lower interface are connected to form a vertical channel, and the left interface and the right interface are connected to form a horizontal channel. The connector assembly is arranged in the vertical channel, and the upper end of the connector assembly is located at the intersection of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com