Hydraulic cylinder for lifting platform in caustic soda production process

A production process and lifting platform technology, applied in the field of hydraulic cylinders, can solve problems such as affecting work efficiency, weak impact resistance, and easy aging of rubber pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

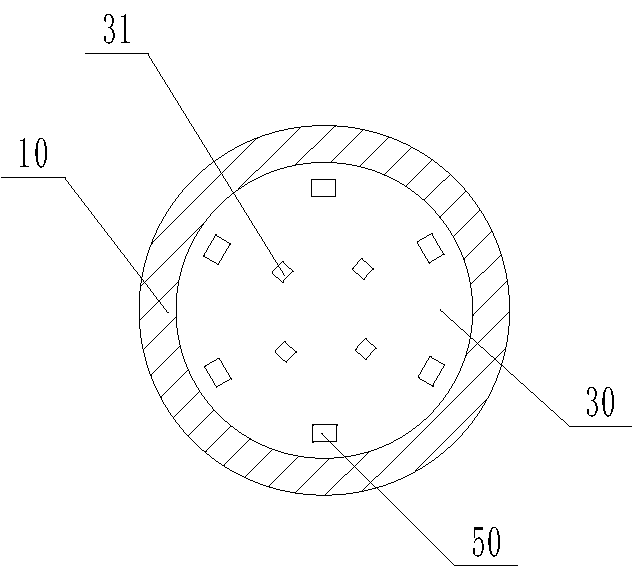

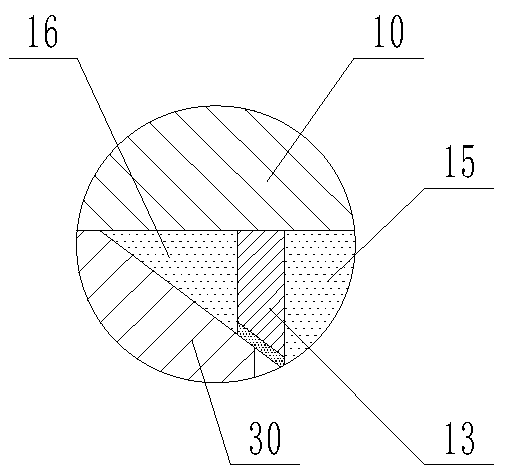

[0020] The reference signs in the drawings of the specification include: cylinder barrel 10, fixed cylinder head 11, pressure relief groove 12, retaining ring 13, oil inlet chamber 14, oil return chamber 15, airtight chamber 16, movable cylinder head 20, groove 21. Piston 30, protrusion 31, first permanent magnet 40, second permanent magnet 50.

[0021] The embodiment is basically as attached figure 1 , figure 2 with image 3 Shown: the hydraulic cylinder used for lifting the platform in the caustic soda production process, including the cylinder barrel 10 and the movable cylinder head 20 connected with the cylinder barrel 10 by bolts. The left and right ends of the cylinder barrel 10 are equipped with hydraulic pipes, and the right end of the cylinder barrel 10 is provided with a fixed cylinder head 11 integrally formed therewith. The inner wall of the cylinder 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com