Unloading one-way valve

A one-way valve, valve body technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve problems such as large power loss of hydraulic pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

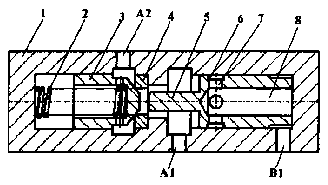

[0012] The reference signs in the accompanying drawings include: valve body 1, spring 2, cone valve 3, cone valve seat 4, control piston 5, unloading ring groove 6, throttle hole 7, piston cavity 8, oil inlet A1, Control oil port B1 and oil outlet A2.

[0013] The embodiment is basically as attached figure 1 Shown: the unloading check valve of this embodiment, the valve body has a hollow chamber, the chamber is divided into a left chamber and a right chamber, the left chamber and the right chamber communicate through the connecting hole in the middle, the left chamber There is an oil outlet on the chamber, an oil inlet on the left side of the control piston on the right chamber, a ring groove on the oil inlet on the side wall of the right chamber, and a control valve on the right side of the piston. The oil port has a concave ring groove on the side of the control pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com