Straw particle combustion furnace

A combustion furnace and particle technology, applied in the direction of air heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of indoor air pollution, complicated operation, etc., and achieve the effect of reasonable structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with the embodiment of accompanying drawing, this implementation model is further described.

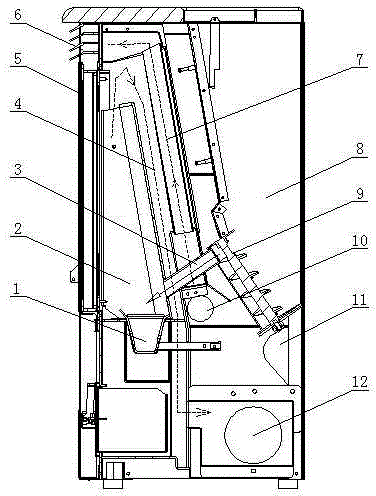

[0010] As shown in the figure, a furnace 2 is left in the front portion of the body of furnace 5 of the vertical cabinet shape, and the bottom of the furnace 2 is equipped with a combustion bucket 1, and a hot air port 6 is arranged on the front of the body of furnace 5 on the upper side of the furnace 2. A vertical flue 4 is left on the rear side, the upper end of the flue 4 communicates with the upper end of the furnace 2, the lower end of the flue 4 is equipped with a smoke exhaust machine 12, the rear side of the flue 4 is equipped with a blowing pipe 7, and the blowing pipe 7 The upper end of the blower pipe 7 communicates with the hot air outlet 6, and the lower end of the blower pipe 7 is equipped with a blower 10, and the rear side of the blower pipe 7 has a storage chamber 8, and a feed pipe 3 is arranged between the bottom of the storage chamber 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com