Laser focus test and laser energy assessment device

A laser energy and focus testing technology, applied in testing optical performance and other directions, can solve the problems of high energy measurement cost of precision instruments, difficulty in confirming the optimal welding focal length, inaccurate visual inspection of laser welding focal length, etc., and achieve high practical value and promotion significance. , The effect of shortening the confirmation time and improving the debugging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

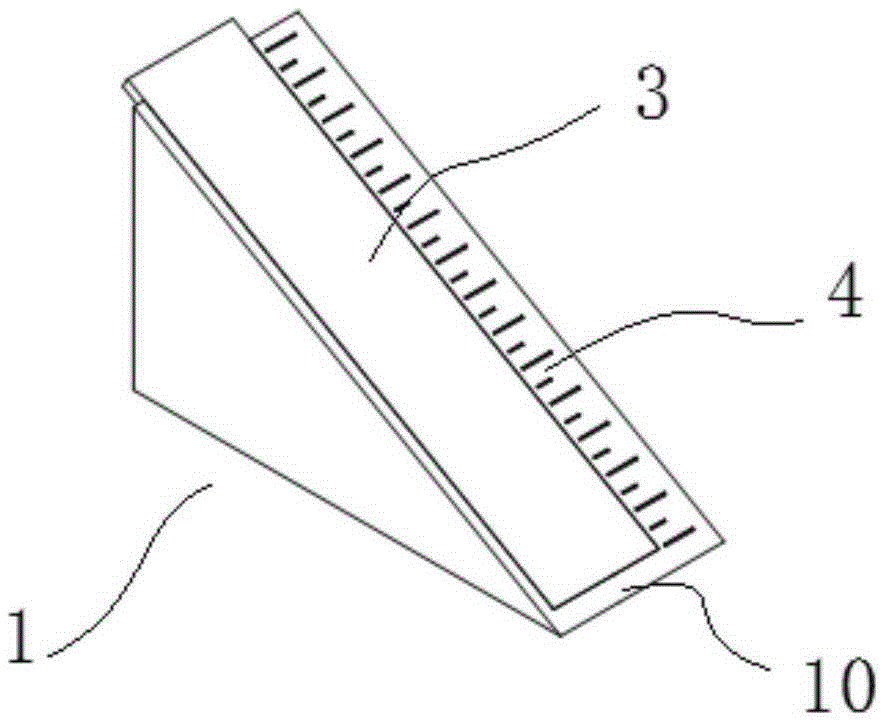

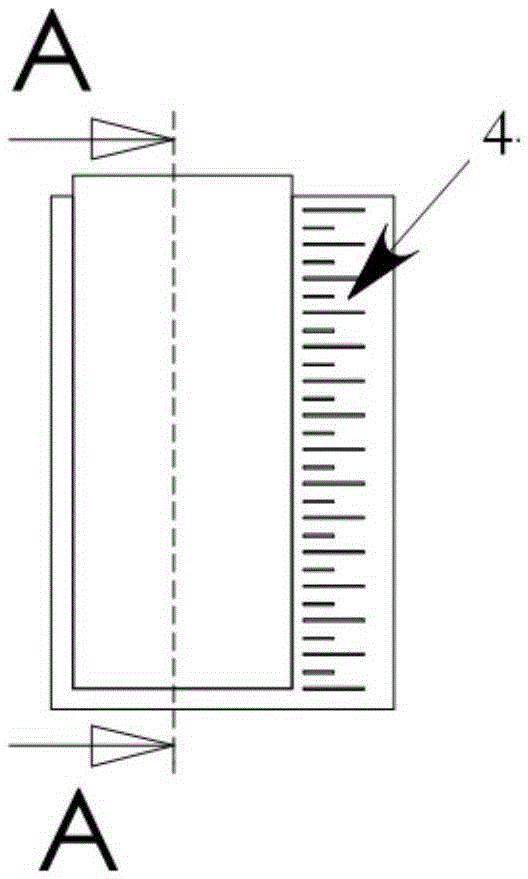

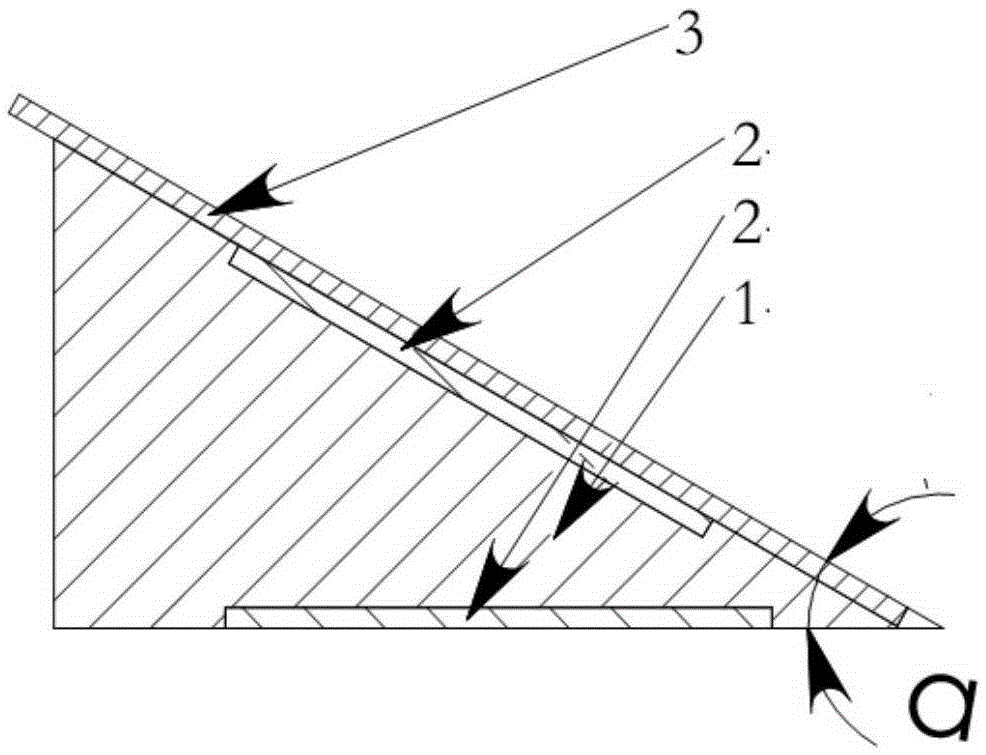

[0017] see Figure 1-3 As shown, a laser focus test and laser energy evaluation device includes a substrate 1, the substrate has an inclined surface 10 with a preset angle and a reference bottom surface for contact with the welding plane, and the inclined surface is provided with a A test plate 3 for laser energy evaluation by laser dotting, the inclined surface is provided with a scale 4 for measuring the distance of different laser dots and calculating the moving distance of the laser focus; the scale is aligned parallel to the test plate and arranged on the inclined face.

[0018] Preferably, the reference bottom surface is in contact with the lower end of the inclined surface 10 and forms a preset angle.

[0019] Further, the whole of the base body is in the shape of a rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com