Crucible lifting and rotating serial weighing device for Eschka sulfur detector

A technology of Iris sulfur measuring instrument and weighing device, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high labor intensity for operators and inaccurate measurement results, and improve weighing efficiency and motion stability Good, reduce the effect of weighing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

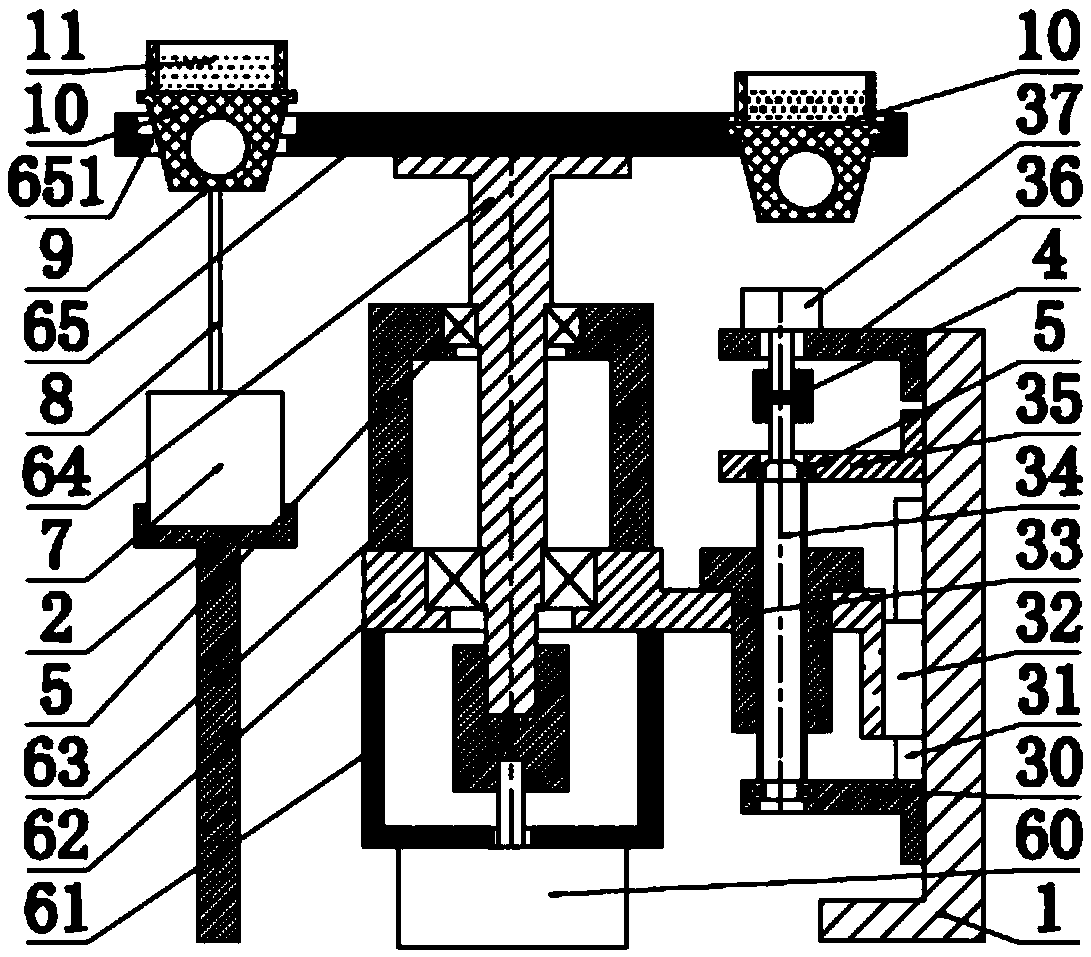

[0014] see figure 1 As shown, a crucible lifting and rotating serial weighing device for an Izod sulfur meter of the present invention includes an L-shaped frame 1, a crucible lifting module and a crucible rotating module installed on the L-shaped frame 1, and the The balance 7 on the balance frame 2, the weighing rod 8 and the weighing pan 9.

[0015] see figure 1 As shown, the crucible lifting module includes a first motor frame 36, an upper bracket 35, a guide rail 31 and a lower bracket 30 installed on the L-shaped frame 1 from top to bottom, and a nut 33 installed on the lead screw 34. The slider 32 on the guide rail 31; the first motor frame 36 is equipped with a first motor 37, and the output shaft of the first motor 37 is connected to the upper end of the leading screw 34 through a coupling 4; the two ends of the leading scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com