Capacitive equipment electrified detection end screen sampling device

A capacitive device, live detection technology, applied in the direction of measuring device, measuring device casing, measuring current/voltage, etc., can solve the problems of low efficiency, inability to carry out the live detection work smoothly in the insulation state, and insufficient safety distance, etc., so as to prevent errors , Ensure safe and stable operation, and prevent equipment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

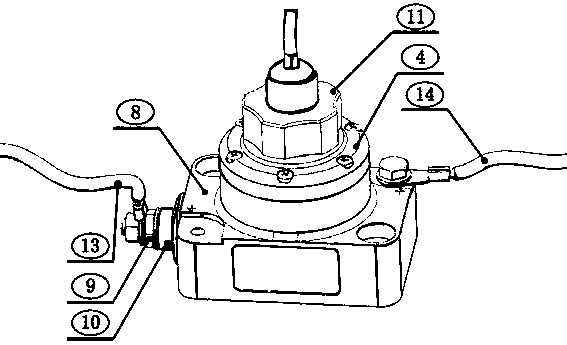

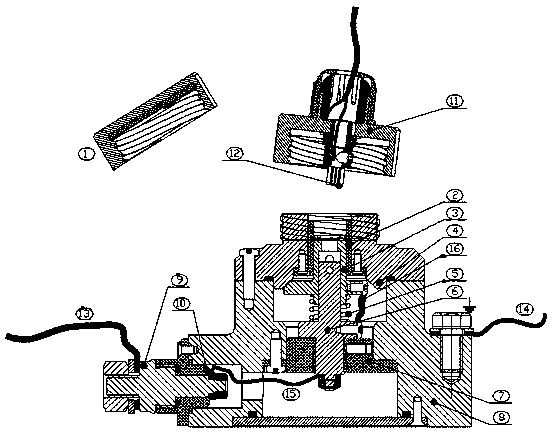

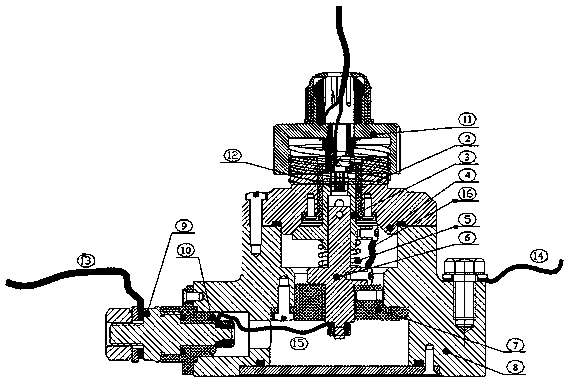

[0024] The present invention is a capacitive equipment live detection final screen sampling device, which includes an upper rotating mechanism, a middle rotating wiring mechanism and a bottom fixing mechanism. The rotating mechanism is connected to the rotating wiring mechanism, and the lower part of the rotating wiring mechanism is connected and fixed. mechanism.

[0025] The rotating mechanism includes: a sealing cover 1 , a detection joint 11 and a detection core 12 . Wherein the sealing cover 1 is used for sealing the equipment when not in detection. The sealing cover 1 can be covered on the detection joint 11, and the detection core 12 is connected to the detection joint 11. When performing detection, a detection joint 11 with a detection core 12 is used.

[0026] The rotary wiring mechanism includes: insulating guide sleeve 2 , sliding contact 3 , ground cover 4 , return spring 5 and flexible wire 16 . The sliding contact 3 is connected to the conductive column 6 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com