High voltage cable laying support used for tunnel construction

A technology for high-voltage cables and low-voltage cables is applied in the field of high-voltage cable laying brackets for tunnel construction, which can solve the problems of large lighting and power requirements, changes in construction sites, and high construction costs, so as to improve smoothness, use safety, and reduce electric energy. Loss and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

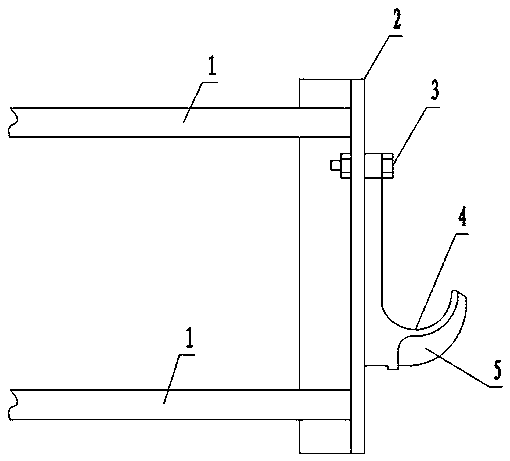

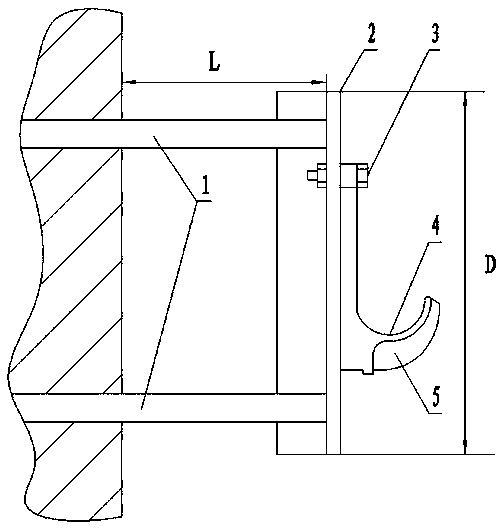

[0014] Example. A high-voltage cable laying support for tunnel construction, consisting of figure 1 , 2 As shown, it includes two supporting steel bars 1 arranged horizontally, and an equilateral angle steel 2 is connected between the two supporting steel bars 1; one side of the equilateral angle steel 2 is fixedly connected with the ends of the two supporting steel bars 1, and the A cable hook 4 is connected with a bolt 3 on one side.

[0015] The bottom of the cable hook 4 is provided with a reinforcing rib 5, the radius of the cable hook 4 is 25 mm to 35 mm, the cable hook 4 is located between two supporting steel bars 3, and the suspended length of the supporting steel bar 1 is equal to or less than The length of the equilateral angle 2.

[0016] During use, one side of the equilat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com