Vibration diaphragm and loudspeaker provided with same

A technology of coating layer and skeleton, applied in the field of loudspeakers, can solve the problems of difficulty in balancing the rigidity and compliance of the diaphragm, poor comprehensive performance of the diaphragm, easy deformation and damage, etc., to achieve good acoustic performance and meet the requirements of high sound quality , the effect of great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

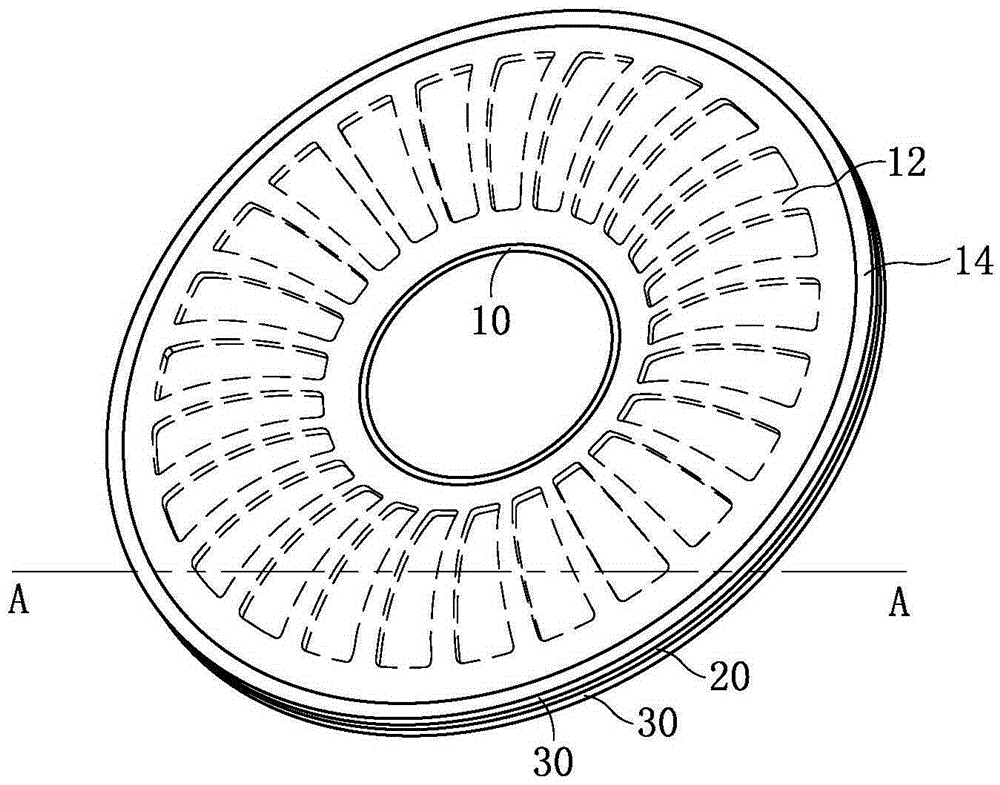

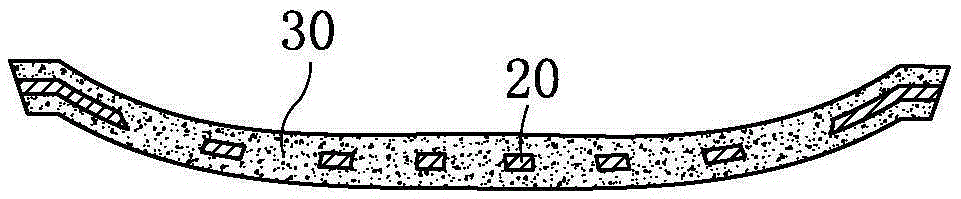

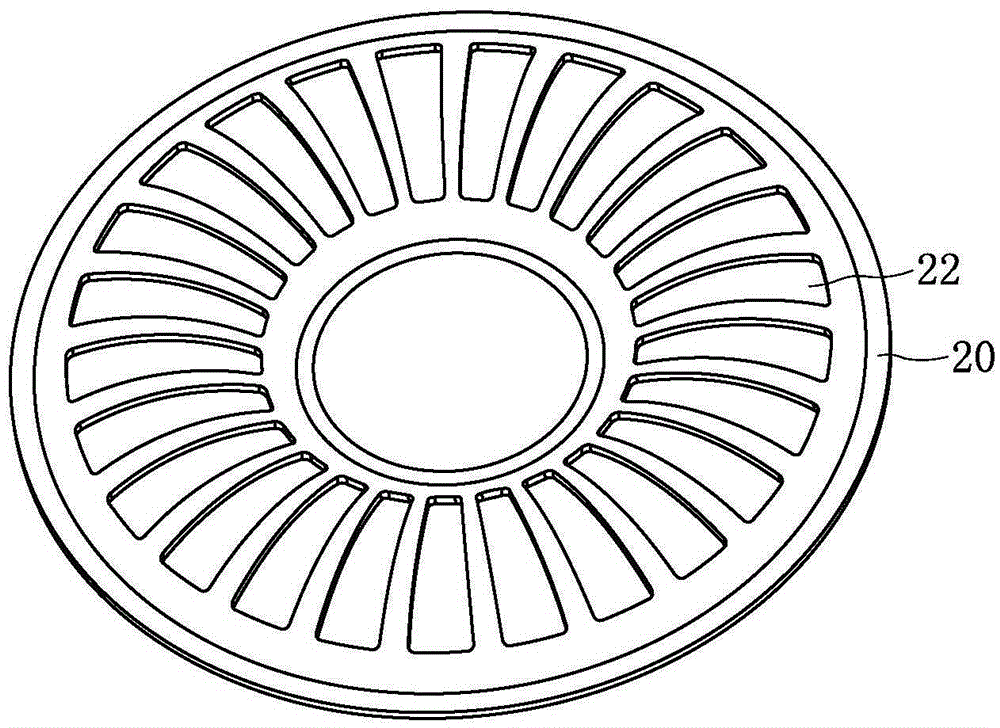

[0027] Such as figure 1 , figure 2 and image 3 Commonly shown, a vibrating membrane has a circular structure, and is sequentially provided with an edge part 14 , a ring part 12 and a central part 10 connected as one from the outside to the inside. The diaphragm includes a skeleton 20, the structure of which is the same as that of the whole diaphragm, and is also sequentially connected with an edge portion, a ring portion and a central portion from outside to inside. A plurality of openings 22 are distributed on the ring portion of the framework 20, and both sides of the framework 20 are covered with a film layer 30, and the material of the film layer 30 fills each opening 22, that is, the covering layers on both sides of the framework 20 The film layer 30 is connected as a whole at the opening 22 . In practical applications, the film layer 30 may only be covered on one side of the frame 20 according to the performance requirements of the diaphragm.

[0028] Such as ima...

Embodiment 2

[0034] A loudspeaker includes a vibrating system and a magnetic circuit system. The vibrating system includes a vibrating membrane and a voice coil combined together. The vibrating membrane is the vibrating membrane described in Embodiment 1.

[0035] Since the loudspeaker of the present invention adopts the diaphragm described in Embodiment 1, it has better acoustic performance, can meet people's requirements for high sound quality of electronic equipment, has higher stability and reliability, and has a longer service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com