Energy-applied dust removal treatment system for removing pollutants in high-temperature polluted gas and its inertial conflict energy recovery and dust removal device

A technology for polluting gases and pollutants, which is applied in the field of inertial conflict energy recovery and dust elimination devices, can solve the problems of reduced processing efficiency, reduced processing efficiency, and is not easy to detach, so as to minimize the dust collection load, ensure the residence time, The effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, the energy utilization type dust removal treatment system for removing pollutants in high temperature polluted gas and the inertial conflict type energy recovery and dust removal device according to the present invention will be described in detail with reference to the accompanying drawings. The suffixes "device", "unit", "component" and "part" for the constituent elements used in the following description are given and mixed in consideration of the convenience of preparing the description, and do not have mutually distinguishing meanings or functions.

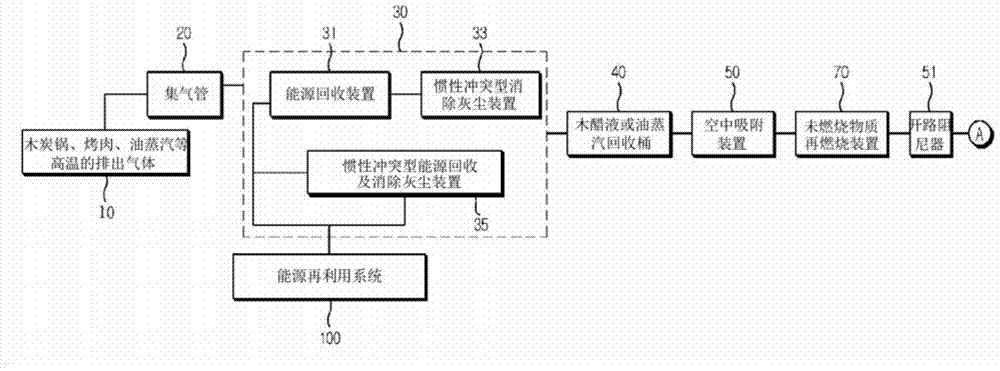

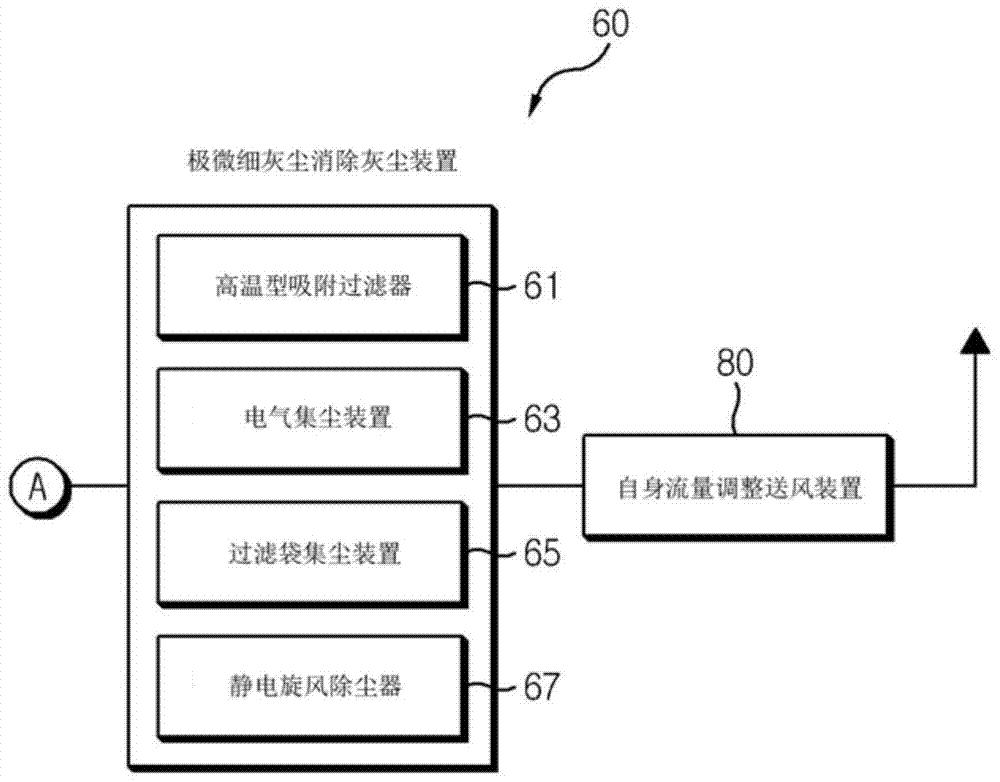

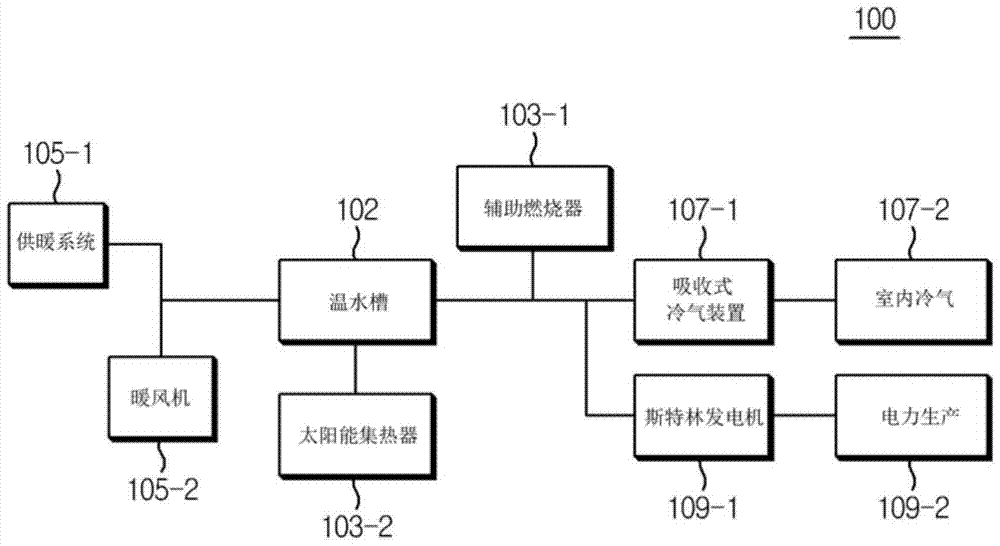

[0047] figure 1 and figure 2 It is a structural block diagram showing the structure of an energy-applied dust removal treatment system that removes pollutants in high-temperature polluted gas, which is an embodiment of the present invention. As shown in the figure, an embodiment of the present invention, that is, the structure of an energy-applied dust removal treatment system that eliminates pollutants ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com