Method and apparatus for carbonating a liquid

A carbonation and liquid technology, applied in chemical instruments and methods, distribution devices, liquid distribution, etc., can solve the problems of limited and non-carbonated finished beverages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Carbonation is the process of dissolving carbon dioxide in an aqueous solution under pressure. It is commonly used in the production of soft drinks, tonic water and other carbonated beverages. Effervescence is the evolution of gas from an aqueous solution. In many consumer products, such as soft drinks (eg, Coca-Cola, 7-Up, and Pepsi), carbonation (more specifically, effervescence of evolved gas) enhances the flavor of the beverage. Carbonated drinks contain dissolved carbon dioxide. Carbon dioxide dissolved in water (CO 2 ) process is called carbonation. Carbonation can occur naturally from fermentation or mineral sources. However, most carbonated soft drinks utilize carbon dioxide artificially added to the drink for carbonation. Artificial carbonation is usually done by dissolving carbon dioxide in a liquid under pressure.

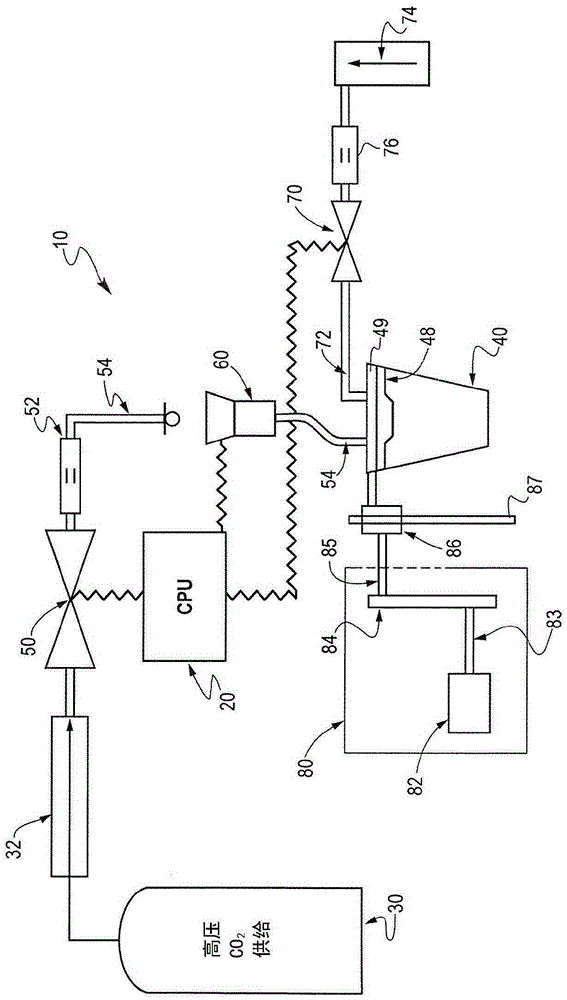

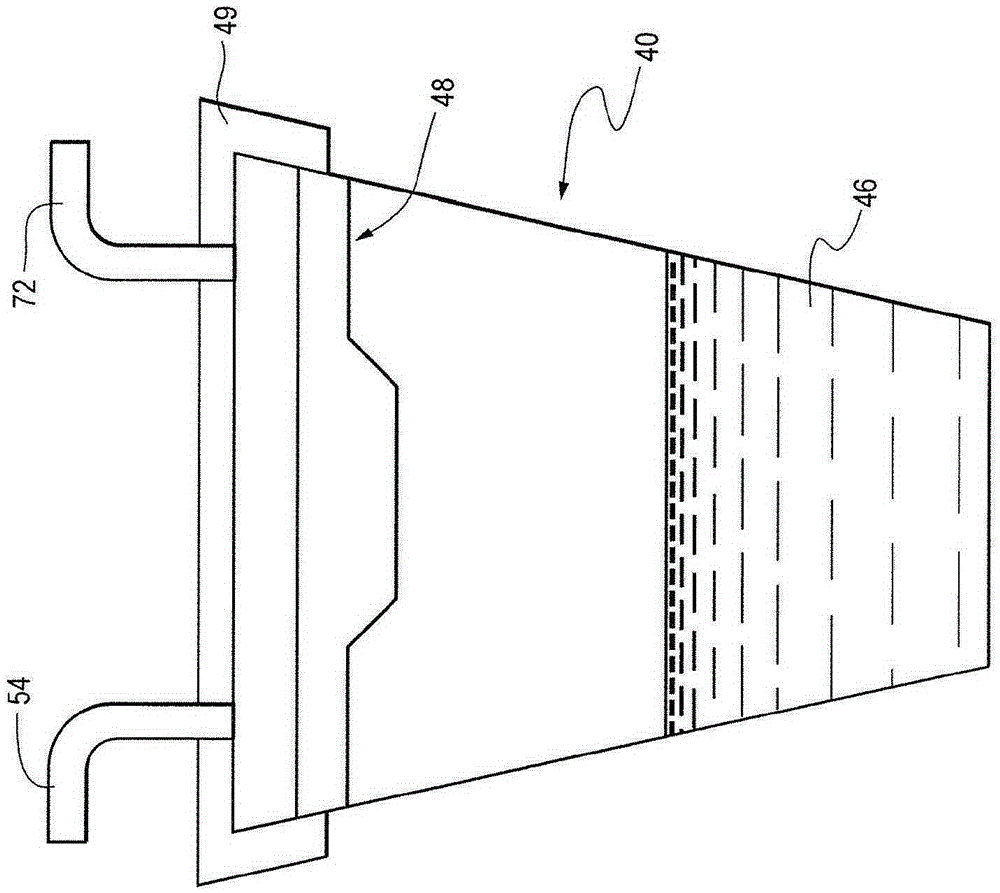

[0016] The invention can be used for carbonation of liquids in containers. The liquid was not carbonated when it was placed in the contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com