Cutting tool

A cutting tool and cutting resistance technology, which is applied in the direction of manufacturing tools, metal processing equipment, milling machine equipment, etc., can solve the problems of cumbersome tool adjustment and achieve the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0024] The cutting tool of this embodiment will be described. First, the basic form of the cutting tool according to the present embodiment will be described. The cutting tool of this embodiment can be used, for example, when a hole is formed in a workpiece.

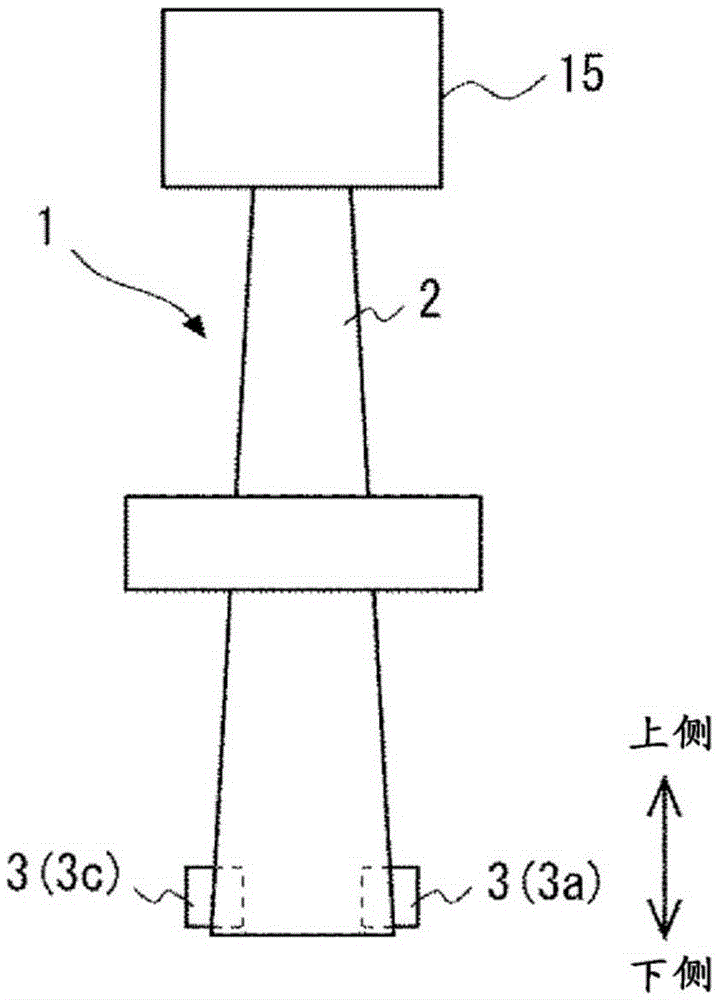

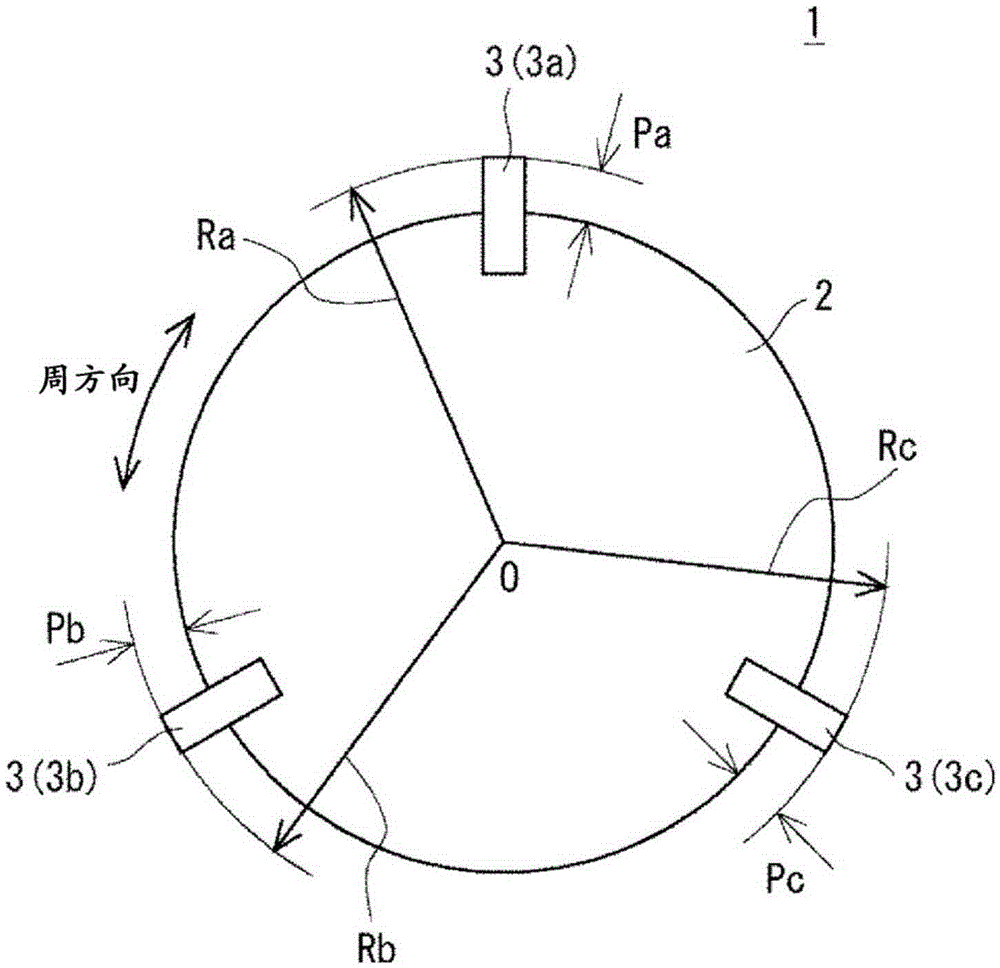

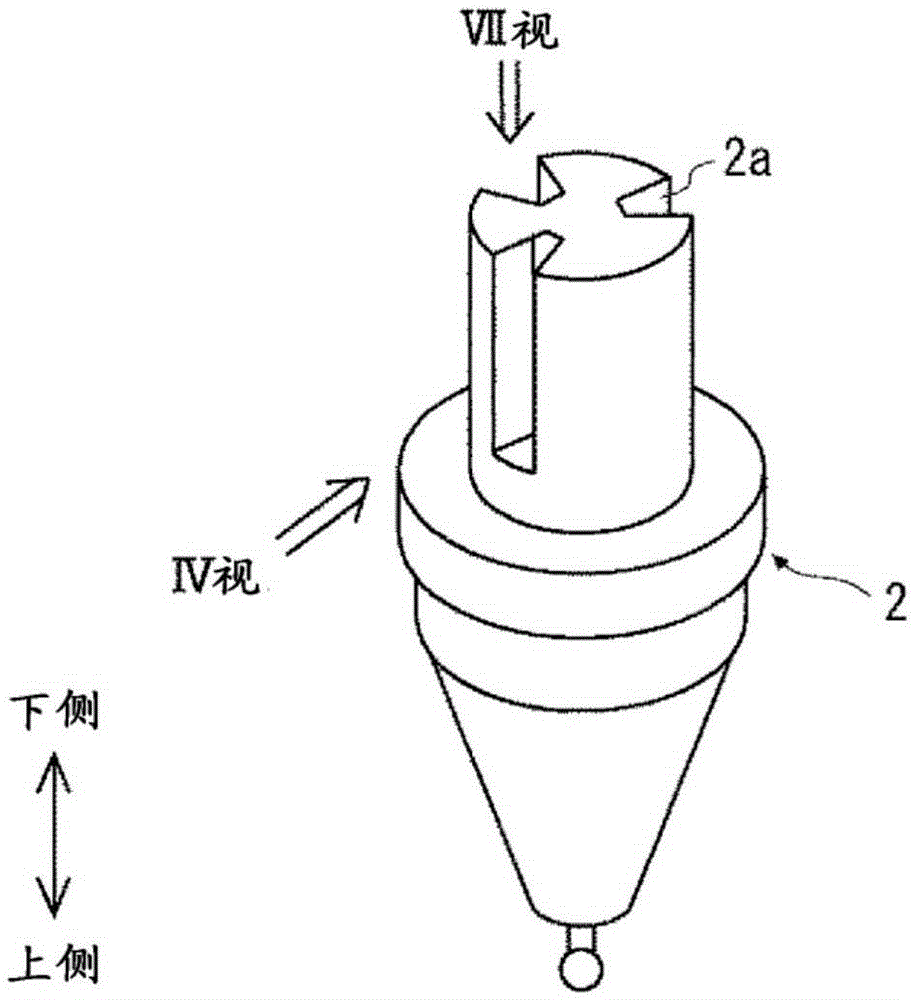

[0025] figure 1 It is a front view schematically showing a state in which the cutting tool 1 according to the present embodiment is connected to the rotary drive mechanism of the cutting device. figure 2 It is a bottom view schematically showing the cutting tool 1 of this embodiment. like figure 1 as well as figure 2 As shown, the cutting tool 1 includes a tool holder 2 and a tool 3 .

[0026] like figure 1 as well as figure 2 As shown, the tool holder 2 has a substantially conical shape as its basic form, and for example, its upper end is connected to the rotation shaft of the rotary drive mechanism 15 of the cutting device. A cutter 3 is attached to the lower end portion of the cutter holder 2 along the circ...

Embodiment approach 2

[0060] The cutting tool 20 of the present embodiment is composed of the cutting tools 21a, 21b, and 21c made of the same material. Figure 8 It is a bottom view schematically showing the cutting tool 20 of this embodiment. In addition, since the cutting tool 20 of the present embodiment has substantially the same configuration as the cutting tool 1 of the first embodiment, overlapping descriptions are omitted, and the same reference numerals are assigned to the same elements.

[0061] As described above, if the protruding amount Pa of the tool 21a from the tool post 2 in the radial direction of the tool post 2 is greater than the protruding amounts Pb, Pc of the knives 21b, 21c from the tool post 2 in the radial direction of the tool post 2 Larger, the materials of the cutters 21a, 21b, 21c are approximately equal, and the installation angles of the cutters 21a, 21b, 21c are approximately equal, the cutting resistance of the cutter 21a will be greater than that of the cutters ...

Embodiment approach 3

[0066] The cutting tool 30 of the present embodiment is composed of the cutters 31a, 31b, and 31c made of the same material. Figure 9 It is a front view schematically showing the cutting tool 30 of this embodiment. Figure 10 It is a bottom view schematically showing the cutting tool 30 of this embodiment. In addition, since the cutting tool 30 of the present embodiment has substantially the same configuration as the cutting tool 1 of the first embodiment, overlapping descriptions are omitted, and the same reference numerals are assigned to the same elements.

[0067] As described above, if the protruding amount Pa of the tool 31a from the tool post 2 in the radial direction of the tool post 2 is greater than the protruding amounts Pb, Pc of the knives 31b, 31c from the tool post 2 in the radial direction of the tool post 2 Larger, the materials of the cutters 31a, 31b, 31c are approximately equal, and the installation angles of the cutters 31a, 31b, 31c are approximately eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com