Automatic feeder

An automatic feeding and transmission rod technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of unreasonable scraping device design, mildew and deterioration of feed, unfavorable pig health, etc., so as to reduce labor and avoid scraping. The effect of material dead angle and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

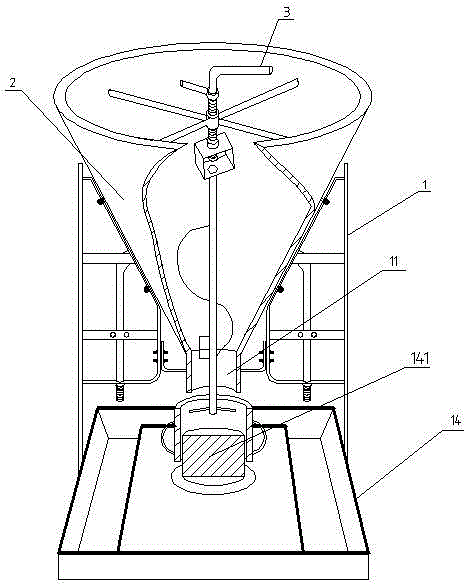

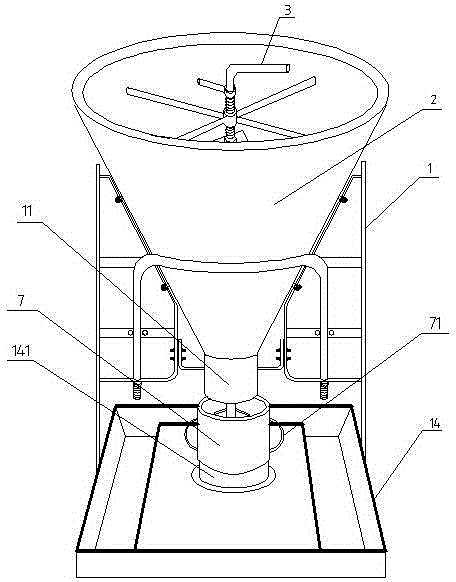

[0026] as attached Figure 1-4 As shown, the automatic feeder of the present invention includes a support 1 , a storage tank 2 , a discharge device 3 , and a transmission rod 4 . A material storage tank 2 is fixedly installed on the bracket 1; the material storage tank 2 is in an inverted conical shape, and a discharge pipe 11 is provided at the lower end.

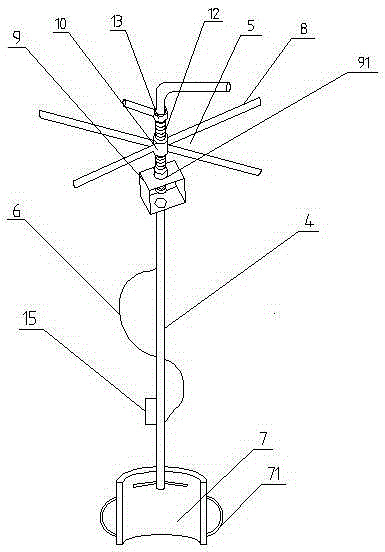

[0027] Discharging device 3 comprises transmission rod 4, mounting frame 5, material shifting part 16, material shifting sleeve 7; mounting frame 5 is fixedly arranged on the inwall of material storage tank 2; transmission rod 4 is installed on the mounting frame 5, and transmission rod 4. It can rotate along its axial direction. The lower end of the transmission rod 4 passes through the discharge pipe 11 and then is fixedly connected to the dial sleeve 7. The transmission rod 4 is provided with a dial member I6, and the dial member I6 is large on the top and small on the bottom. S type, the lower part extends into the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com