Patents

Literature

45results about How to "Ready-to-eat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of convenient and instant sweet wine

InactiveCN103540468AImprove sensory qualityEasy to storeAlcoholic beverage preparationMicroorganism based processesLeesFreeze-drying

The invention discloses a processing method of a convenient and instant sweet wine by a freeze-drying technique, which comprises the following steps: cleaning glutinous rice, immersing, boiling, spreading, mixing with distillery yeast, fermenting, sterilizing, centrifugating to take vinasse, blending, and carrying out freeze-drying to obtain a dry sweet wine block; and producing a dry sweet wine block seasoning bag from the sweet wine which is subjected to vinasse removal by centrifugation. The convenient and instant sweet wine has the advantages of favorable rehydration property, pure and fragrant vinosity, complete nutrients and high product quality, and is convenient to carry.

Owner:汨罗市长乐甜酒产销专业合作社 +1

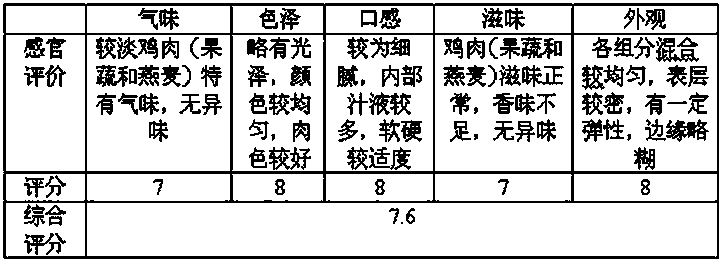

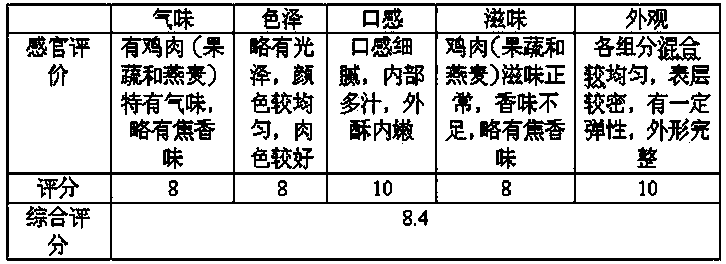

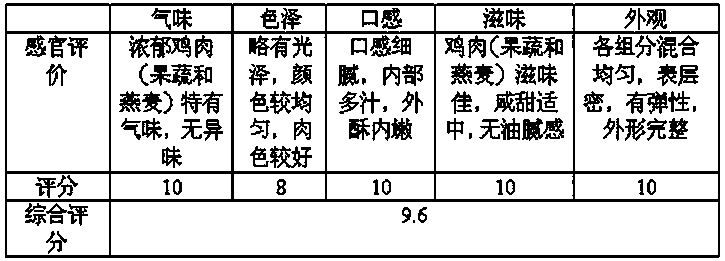

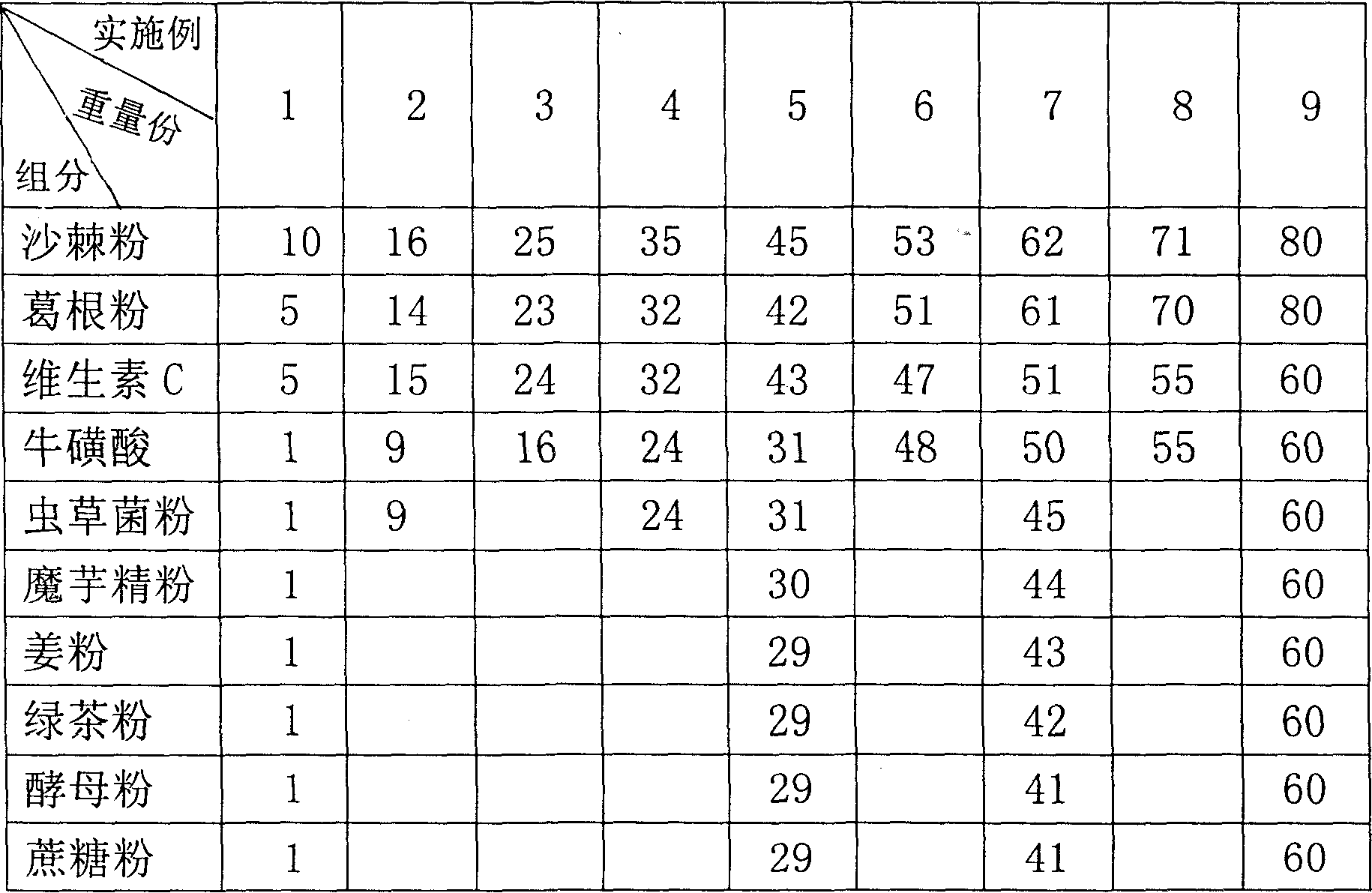

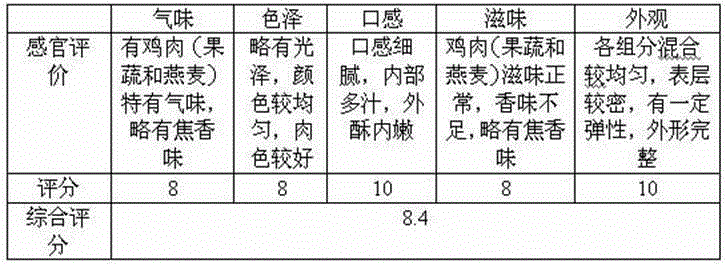

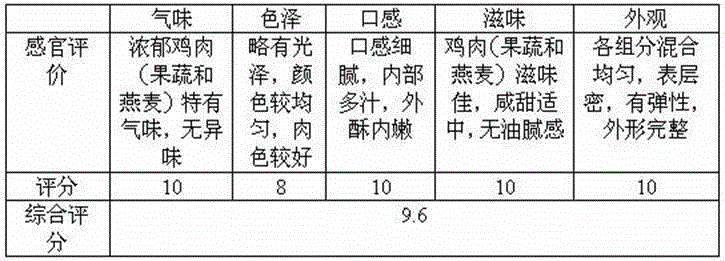

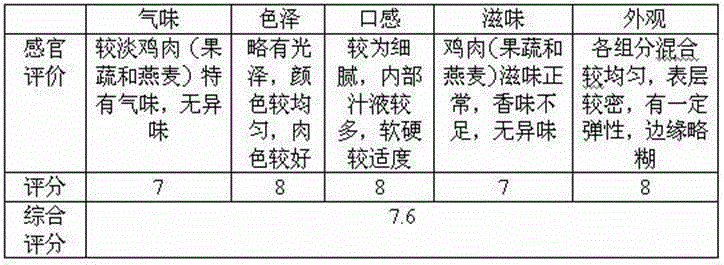

Chicken jerky and preparation method thereof

InactiveCN103462064ASoft textureChange the characteristics without dietary fiberFood preparationFruit juiceAdditive ingredient

The invention discloses chicken jerky and a preparation method thereof, belonging to the field of a food processing technology. By taking chicken, fruit and vegetable dregs and oats as main raw materials, the preparation method comprises the following steps of freezing and preserving the raw materials in a freezing chamber firstly, baking and roasting, and then spraying fruit juice on the surface of a semi-finished product to obtain the product. The preparation method is simple and convenient to operate, can fully keep the nutritional ingredients of chicken, effectively combine the nutritional ingredients of the fruits and vegetables and the oats, and can effectively prevent the nutritional ingredients and active ingredients from loss and destruction by adopting a special baking process; furthermore, the chicken jerky forms a special fruit, vegetable and chicken compound flavor, has good mouthfeel and smooth and seamless appearance, can be eaten instantly, and can be used as snack foods such as small snacks, or used as geriatric foods with low fat and low calorie.

Owner:KUNMING UNIV OF SCI & TECH

Sobering-up composition

InactiveCN1895340AImprove the activity of anti-alcoholic enzymesAvoid damageNervous disorderPill deliveryVitaminFood science

Owner:易青

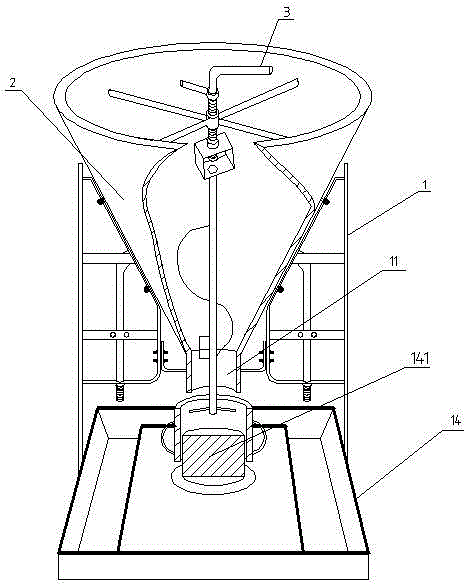

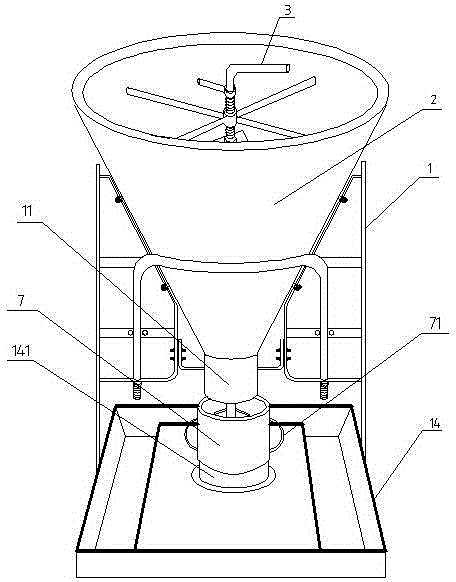

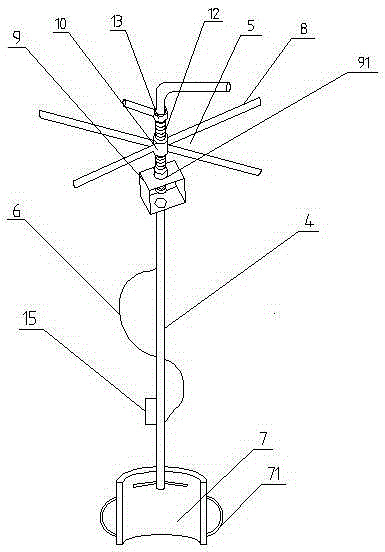

Automatic feeder

InactiveCN105379634AAvoid scraping cornersSimple device structureAnimal feeding devicesEngineeringHabit

The invention discloses an automatic feeder. The automatic feeder comprises a support, a storage vat, a transmission rod and a discharging device, wherein the inverse-cone-shaped storage vat is fixedly installed on the support, and a discharging pipe is arranged at the lower end of the storage vat; the discharging device comprises an installation frame, the transmission rod, a stirring part I and a stirring sleeve, the installation frame is fixed to the inner wall of the storage vat, the transmission rod is installed on the installation frame and can revolve on its axis, the lower end of the transmission rod penetrates through the discharging pipe and then is fixedly connected with the stirring sleeve, the stirring part I is arranged on the transmission rod, the inner diameter of the stirring sleeve is slightly larger than the outer diameter of the discharging pipe, and one or more lugs are arranged on the outer side wall of the stirring sleeve. The automatic feeder is especially suitable for pig farms. By means of the nosing habit of pigs, when pigs touch the stirring sleeve, the stirring sleeve drives the transmission rod to rotate to enable feed to fall down through the gap between the discharging pipe and the stirring sleeve. The discharging amount can be controlled by adjusting the gap between the discharging pipe and the stirring sleeve.

Owner:陈国武

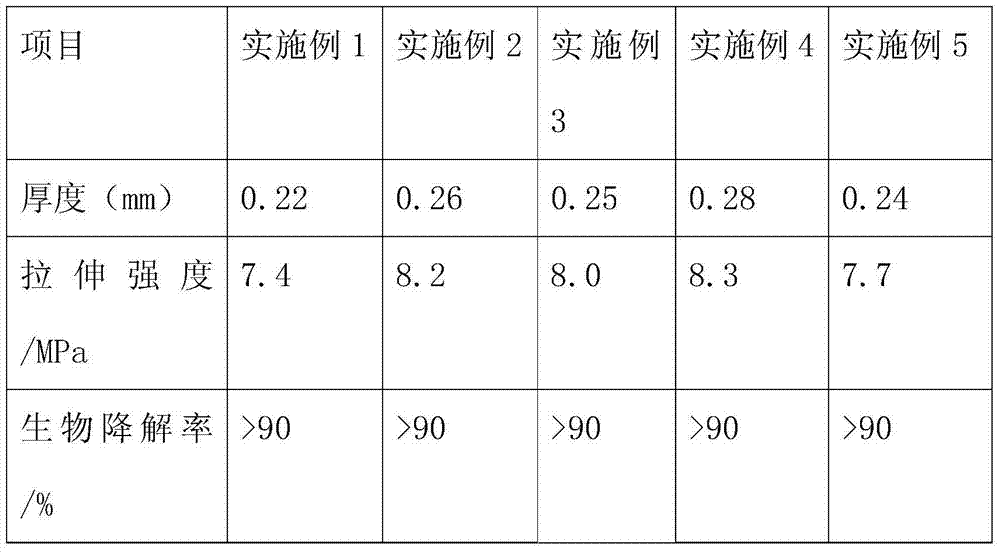

Edible composite film packing material with healthcare function

The invention discloses edible composite film packing material with a healthcare function. The edible composite film packing material comprises, by weight, 40-50 parts of starch, 2-3 parts of edible gum, 0.5-1 part of natural oxidation inhibitor, 3-5 parts of vegetables and 6-10 parts of water. The invention further discloses a preparation method of the edible composite film packing material. The method includes: natural oxidation inhibitor micro-emulsification, vegetable processing, main material processing and film manufacturing to obtain the required packing material. The prepared packing material is edible, degradable, non-toxic, free of pollution, good in overall performance, and simple in preparation process, and the packing material has functions of oxidation resisting and healthcare after being eaten.

Owner:苏州靖羽新材料有限公司

Conveniently seasoned lotus seed and preparation method thereof

The invention relates to a conveniently seasoned lotus seed and a preparation method thereof. The preparation method for the conveniently seasoned lotus seed comprises the following steps: pre-treating raw materials; preparing seasoning liquid; performing vacuum impregnation; cooking and baking; and cooling and packaging. The preparation method provided by the invention is simple in process, short in production period, low in equipment demand and high in operability. The nutrition of the lotus seed can be kept according to the preparation method provided by the invention. The product has the advantages of ready-to-eat, heavy flavor, crisp tasty property, and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for breaking plant cell wall

InactiveCN1785073APromote absorptionEfficient use ofPlant cellsFood treatmentNutritive valuesPlant nutrition

A method for breaking the wall of plant cell in order to increase the nutritive value of plant includes such steps as washing raw plant, baking until its water content is 15-40%, heating in pressure tank at 50-80 deg.C for 10-40 min, vacuumizing for 1-3 hr, and cooling.

Owner:郑铁钢 +1

Preparation method of Maca active extracts

InactiveCN102697039AAvoid enzymatic digestionAvoid lossFood preparationFreeze-dryingAdditive ingredient

The invention provides a preparation method of Maca active extracts. According to the method, firstly, fresh Maca roots or dry Maca roots are pre-treated, then, percolation is carried out for twice after the treatment by a pre-heated mixed solvent, freeze drying is carried out after additives are added into concentrated liquid, and the Maca active extracts are obtained. The method provided by the invention is simple, the operation is easy, the nutrition ingredients and active substances of the Maca are sufficiently and fully integrated, the active ingredient enzymolysis is prevented, and in addition, the loss and the damage of nutrition ingredients and active ingredients can be effectively prevented. The obtained product can realize the instant eating effect, can also be used as raw materials to be made into health care foods in tablets, capsules and the like, or can be added into various kinds of food as additives to realize the application.

Owner:KUNMING UNIV OF SCI & TECH

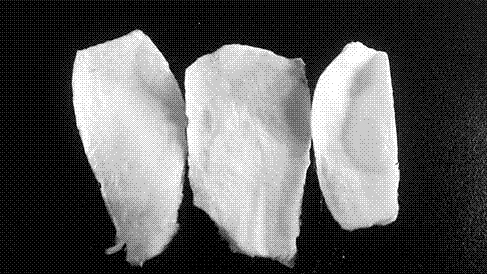

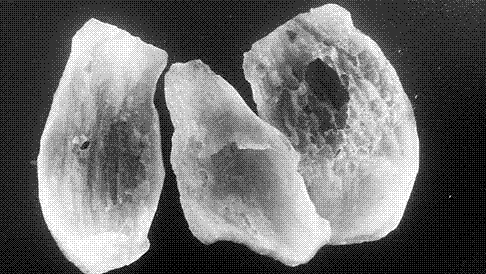

Original instant lanceleaf lily bulb crisp processing method

The invention discloses an original instant lanceleaf lily bulb crisp processing method which includes the steps: cleaning and sectioning lanceleaf lily bulbs and removing lanceleaf lily bulb petals with incomplete appearance and rotten yellowing portions to obtain raw lanceleaf lily bulbs; curing the raw lanceleaf lily bulbs to obtain cured lanceleaf lily bulbs; pre-freezing the cured lanceleaf lily bulbs; placing the cured lanceleaf lily bulbs into a cold trap at the temperature ranging from -42 DEG C to 44 DEG C under the air pressure of 12-14Pa, and drying the cured lanceleaf lily bulbs for 12-15 hours to obtain original instant lanceleaf lily bulb crisp. According to the processing method, advanced vacuum freeze drying technology is applied to processing fresh lanceleaf lily bulbs, and the instant lanceleaf lily bulb crisp capable of retaining nutritional components and original flavor of the fresh lanceleaf lily bulbs is produced and has the advantages of instant edibility, high nutritional components, good sensory quality and the like. The processing method provides technical support for novel lanceleaf lily bulb products, new varieties of the lanceleaf lily bulb products are increased, and the additional value and the market competitiveness of the lanceleaf lily bulb products are improved.

Owner:兰州十百农业生物科技有限公司

Vegetable cell wall breaking technology

InactiveCN105368770AEasy to absorb and utilizeGood for human body to absorbPlant cellsWater contentLivestock

The invention discloses a vegetable cell wall breaking technology capable of being widely applied to the industries including health products, non-staple food, food, medicines, beverages, cosmetics, livestock and the like. According to the technology, the specific operation comprises the following steps: (1) cleaning plant raw materials, drying the plant raw materials, and picking the plant raw materials, so that the water content of the plant raw materials is 15-40%; (2) slowly heating the plant raw materials with the water content being 15-40% in a pressure tank, so that the temperature inside the pressure tank is increased to 60-80 DEG C within 10-40 min, opening a deflation valve of the pressure tank, exhausting air to a vacuum tank with the vacuum degree being -0.02 to 0.1 MPA, so that the inside of the pressure tank forms the vacuum immediately; and (3) keeping the temperature inside the pressure tank to be 50-80 DEG C, so that the water content of the plant raw materials are smaller than or equal to 5% within 1-3 h, closing the deflation valve of the pressure tank, and carrying out artificial cooling in a closed state for reducing the temperature, so as to obtain the product. According to the vegetable cell wall breaking technology, the sufficient absorption and utilization for the plant nutrition ingredients by the human body are facilitated, the mouthfeel is good, and the storage is easy.

Owner:王晓辉

Zongzi leaf rice stickiness reducing nutritional preserved meat flavored zongzi and preparation method thereof

InactiveCN106538956AReady to eatUnique fragranceFood ingredient as taste affecting agentBiotechnologyFood flavor

The present invention relates to zongzi leaf rice stickiness reducing nutritional preserved meat flavored zongzi. The nutritional preserved meat flavored zongzi is prepared from the following raw materials in parts by weight: 95-120 parts of fragrant glutinous rice, 35-55 parts of broomcorn millet, 35-55 parts of polished round-grained rice, 30-45 parts of red kidney beans, 30-45 parts of black beans, 30-45 parts of mung beans, 35-40 parts of preserved meat, 25-35 parts of peanuts, 25-35 parts of red dates, 25-35 parts of Chinese wolfberry fruits, 25-35 parts of haws, 25-35 parts of Chinese chestnuts, 15-30 parts of dried shii-take, 5-10 parts of rice wine, 5-10 parts of chicken essence, 1-5 parts of soy sauce and 5-10 parts of edible salt. The present invention also discloses a preparation method. During the steaming process, the oil juice of the preserved meat permeates into the other raw materials, so that the nutritional preserved meat flavored zongzi has the flavor of the preserved meat and is unique in flavor, sweet but not greasy in taste, and rich in nutritious substances. The raw materials are reasonable in ratios, so that the zongzi is glutinous but not sticky in mouthfeel, and easy to eat, also has a certain health-care function, and is suitable for people at all ages to eat.

Owner:GUANGXI UNIV

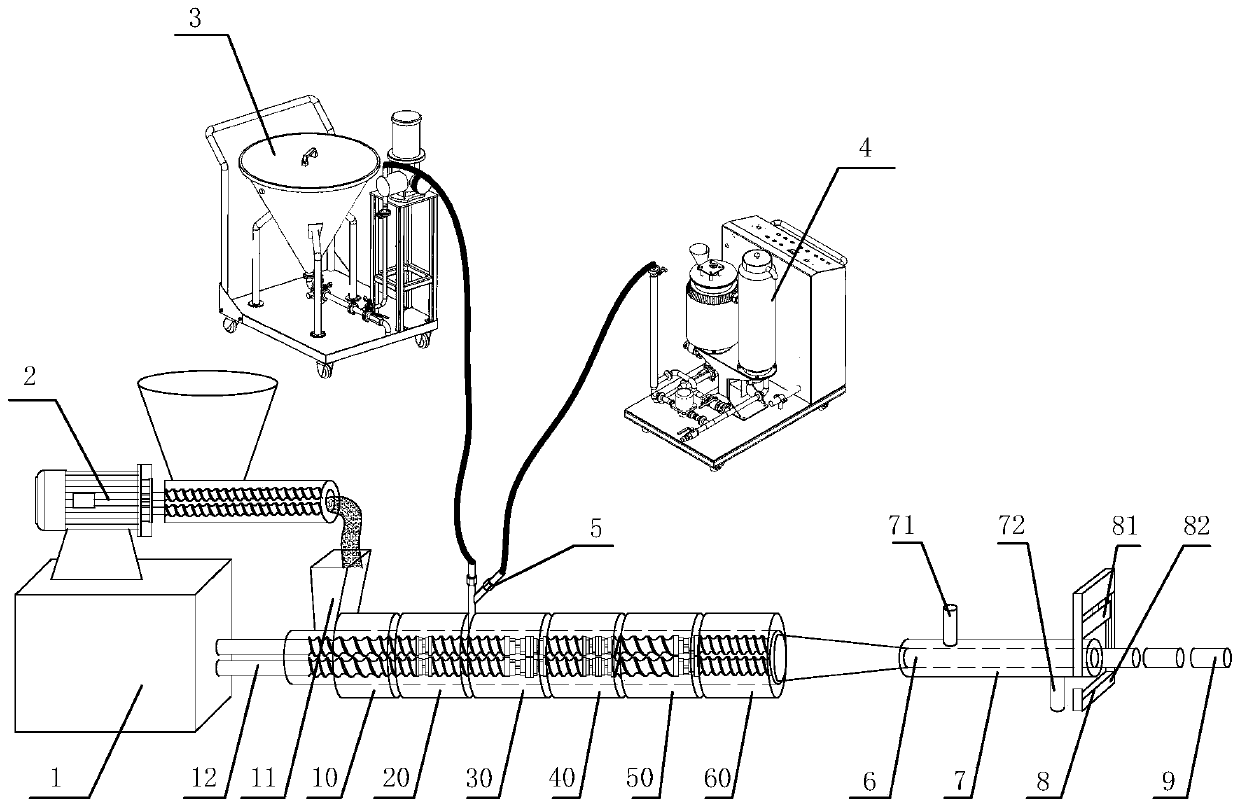

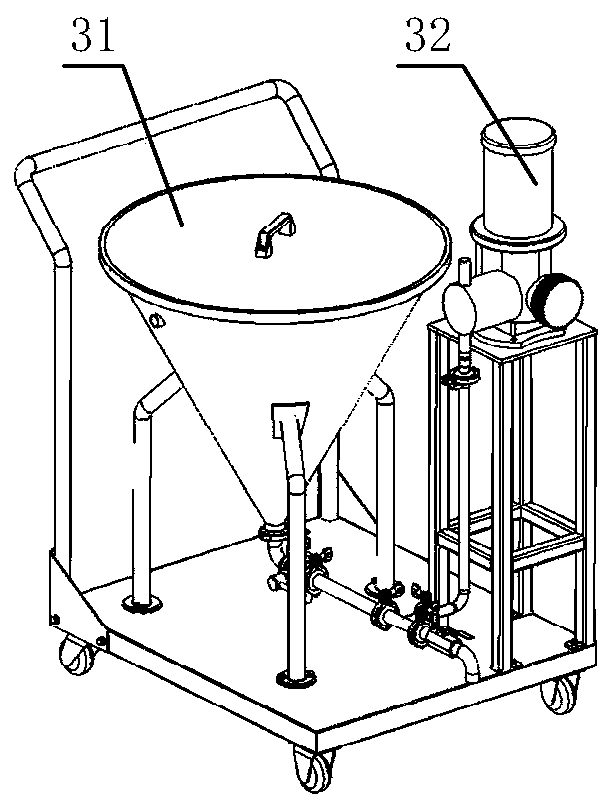

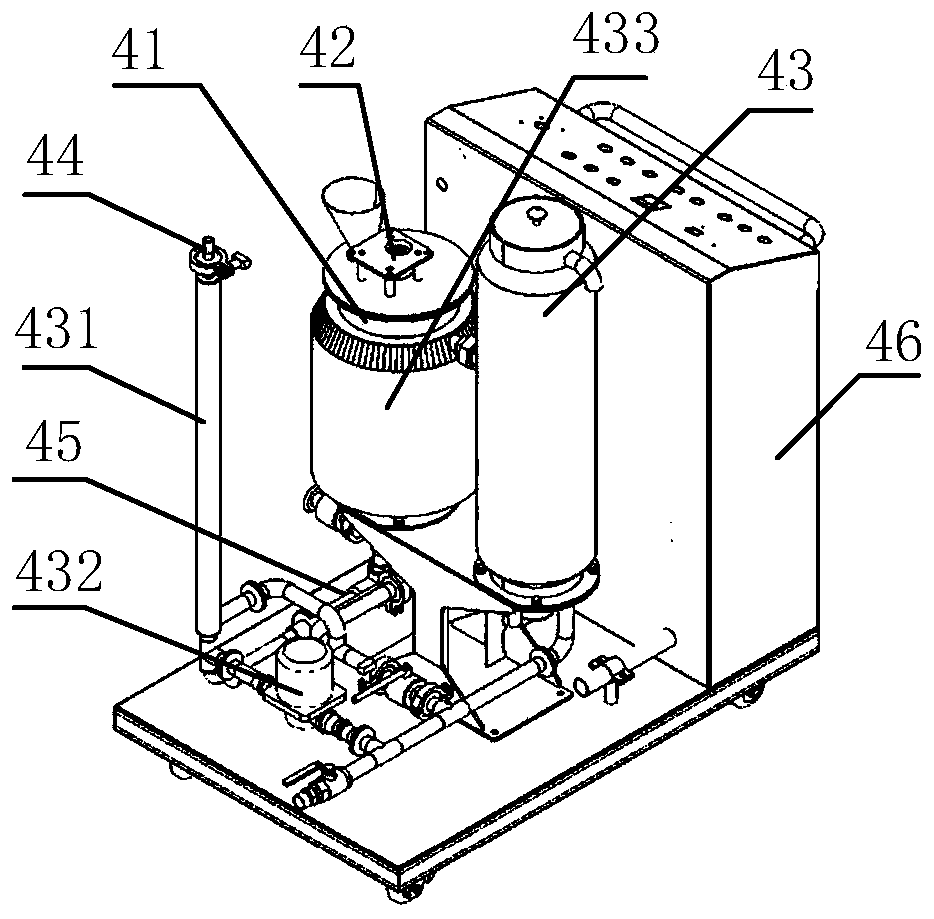

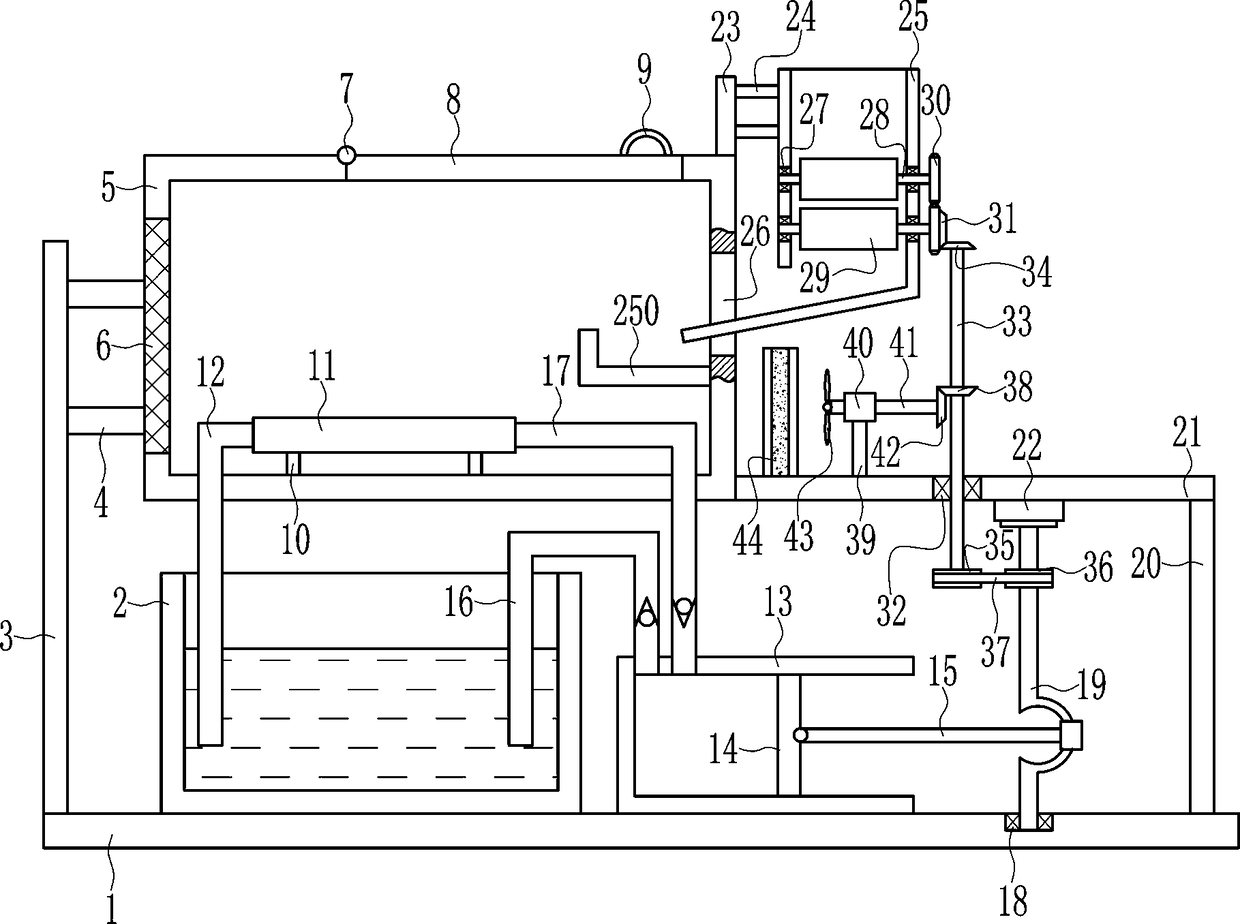

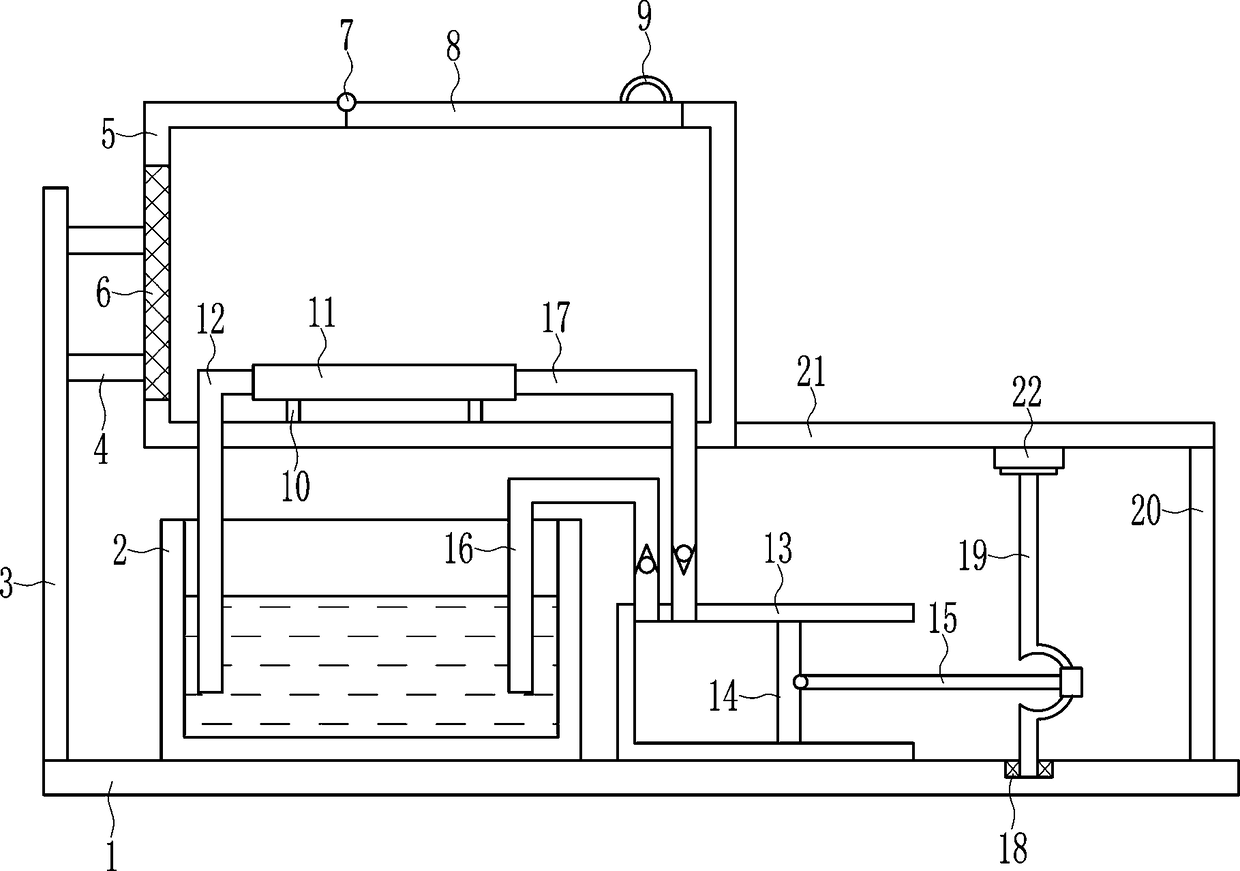

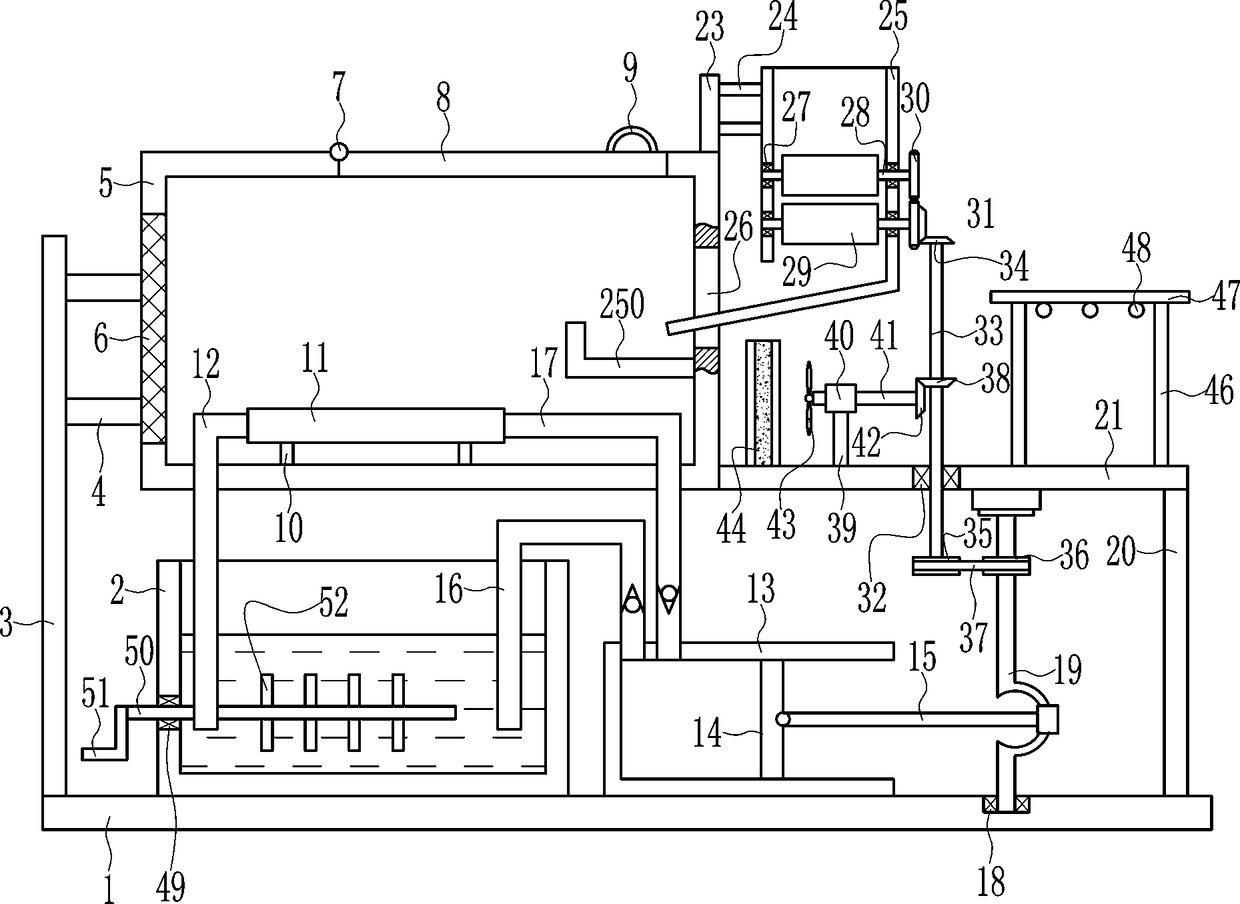

Linked color adjusting and flavor adjusting device and method for preparing plant protein meat

PendingCN110839858ANo emissionsIncrease productivityTransportation and packagingRotary stirring mixersBiotechnologyEngineering

The invention relates to the technical field of plant protein meat production equipment and discloses a linked color adjusting and flavor adjusting device and method for preparing plant protein meat.The device comprises a double-screw extruder, a solid feeder, a first liquid feeder, a second liquid feeder and a three-way joint, and a discharging port of the solid feeder faces a feeding port of the double-screw extruder to provide a powdery material; the first liquid feeder is connected to a first inlet of the three-way joint to provide water, the second liquid feeder is connected to a secondinlet of the three-way joint to provide pigment and essence solution, and an outlet of the three-way joint is communicated to a barrel of the double-screw extruder. By the device, product defects of difficulty in flavor penetration, unattractive meat color, bad meat taste and weak meat sense of the plant protein meat prepared by a high-moisture squeezing method are improved, streamline operation is realized, and technical process is simplified.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI +1

Raw material bag applied to food processing machine

PendingCN109259068AThick and smooth tasteProne to delaminationFood ingredient functionsPsyllium HuskFood processing

The invention relates to a raw material bag applied to a food processing machine. The food processing machine is used for mixing the raw material bag and water and crushing into slurry at a crushing rotating speed of 5000 to 30000r / min; the raw material bag is prepared from 40 to 50 percent of oat, 10 to 25 percent of soybeans, 1 to 20 percent of quinoa and 0.5 to 5 percent of psyllium husk, wherein the soybeans are baked whole beans; the quinoa is in a puffed popcorn form. The food processing machine is used for crushing the raw materials; a manufactured beverage cannot be delaminated; the instant eating is realized; various nutrition elements beneficial to the health are provided; meanwhile, loss and nutrition risk caused by the raw material crushing in advance can be reduced.

Owner:JOYOUNG CO LTD

Method for processing convenient sweet wine capable of being brewed and drunk instantly

InactiveCN106190705AEasy to carryOvercome the defects of the production process and have instantAlcoholic beverage preparationFlavorAdditive ingredient

The invention discloses a method for processing convenient sweet wine capable of being brewed and drunk instantly. The method comprises the steps of washing glutinous rice and performing soaking, steaming, water pouring, distiller's yeast stirring and fermentation, sterilization, separation and taking of distillers' grains, mixing and drying to produce dried sweet wine blocks; and separating sweet wine juice where the distillers' grains are removed to produce dried sweet wine block seasoning bags. The convenient sweet wine capable of being brewed and drunk instantly, which is made according to the method, is good in rehydration capability, has original taste and flavor of wine and is pure, fragrant, sweet, long in guarantee period and convenient to carry, nutritional ingredients are kept completely, and the product quality is high.

Owner:汨罗市长乐甜酒产销专业合作社

Cellaring and flavoring production technology for seasoned pork rib product

The invention relates to the field of food processing and especially rates to cellaring and flavoring production technology for seasoned pork rib product. The production technology comprises the following steps: selecting materials, chopping sauce, mixing materials, containing in a jar, cellaring, aging, sub-packaging and so on. The invention aims to provide the cellaring and flavoring production technology for seasoned pork rib product by which the common and traditional cooking method is changed, so that the bones on pork ribs are softened; thus, the bones can be eaten together with the meat. Accordingly, the pork ribs are processed into seasoning with unique flavor as well as chewy appetizing and digestion-promoting food products. The food products are easy to carry and capable of saving the labor burden in waste cleaning.

Owner:TONGDAO YOUJIAOTOU FOOD CO LTD

Glutinous rice healthy food and preparation method thereof

The invention discloses a glutinous rice healthyfood and a preparation method thereof. The preparation method of the glutinous rice healthyfood comprises the following steps: I, soaking; II, ozone treatment; III, steaming; and IV, molding. The prepared glutinous rice healthy food is soft and glutinous in taste, convenient to store, free of preservatives and other additives, green and healthy.

Owner:宁波北仑戌鸿农业科技有限公司

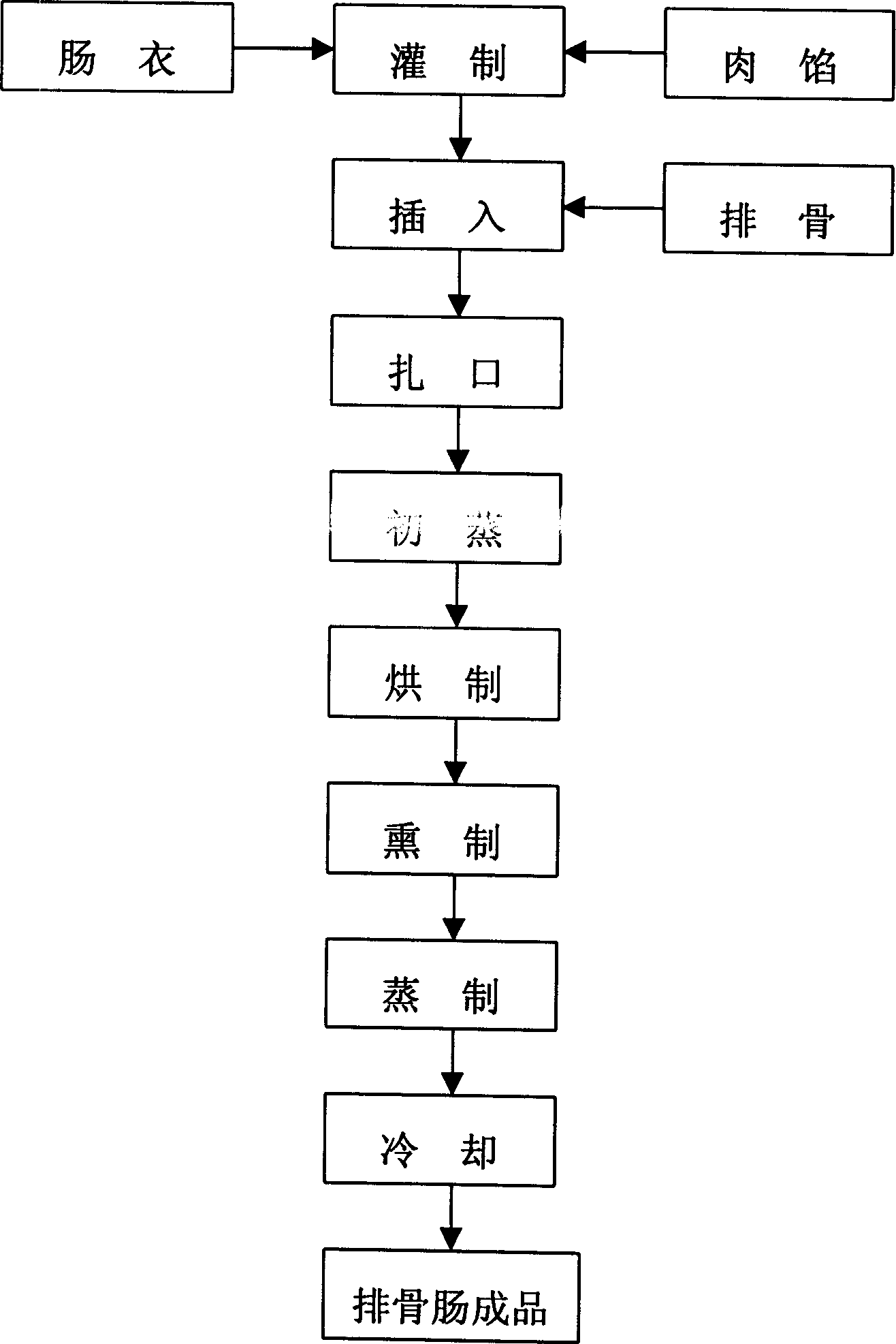

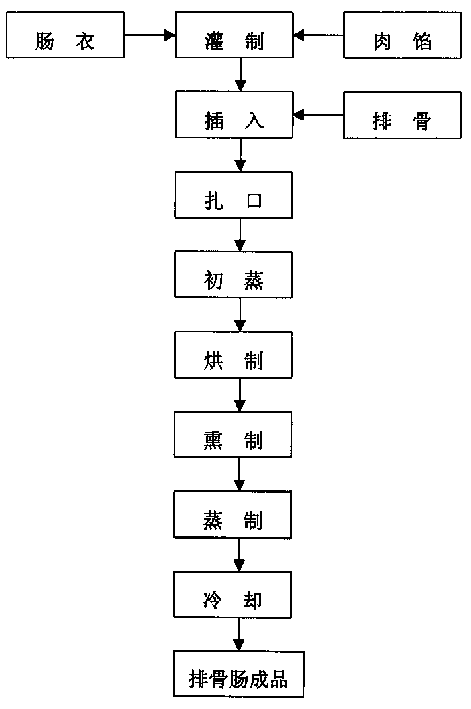

Sausage made of meat from spareribs and its making process

The present invention relates to a spareribs sausage and its production method. Its production method includes the following steps: filling 50% of minced meat into the casing, then inserting the pickled spareribs stirred with flavouring material into the casing filled with the mineral meat, sealing, steaming, baking, fuming and cooling so as to obtain the inveneted product with unique flavour.

Owner:刘鸿兰

Production method of dryness and wetness separation feed for conservation pigs based on semi-liquid state feeding technology

The present invention relates to a production method of a dryness and wetness separation feed for conservation pigs based on a semi-liquid state feeding technology. The production method specificallycomprises the following steps: the feed is manufactured by a dry base feed and a liquid nutritional package feed. The dry base feed is a basic granule compound feed free of enzyme preparations, vitamins and probiotics and the liquid nutritional package feed is a solution containing an organic functional additive after dilution; and when the dry base feed is fed, the dry base feed is combined withthe liquid nutritional package feed to form a semi-liquid feed for feeding by suckling pigs. According to physiological characteristics of the conservation pigs, the semi-liquid state feeding technology is used. After full verifications, the feed effectively solves weaning material-changing stress of the conservation pigs, is suitable for transitional use during weaning, and has obvious effects ofpromoting growth, helping digestion and preventing diarrhea of the conservation pigs. The production method is also not high in equipment requirements, simple to operate, low in costs, and suitable for large-scale promotion and use in pig farms.

Owner:WUHAN JIAJIALE FEED

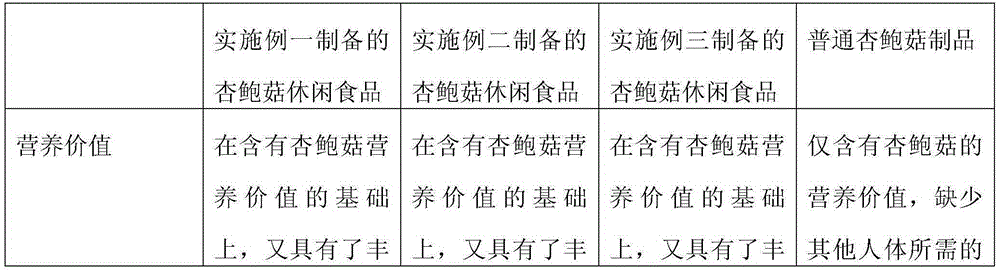

Formula and making technology of pleurotus eryngii leisure foods

InactiveCN105231377AFull of nutritionRich tasteFood ingredient functionsAdditive ingredientManganese

The invention relates to a formula and making technology of pleurotus eryngii leisure foods. According to the pleurotus eryngii leisure foods, pleurotus eryngii is used as a main raw material, black fungus cooking liquid, nori soup, garlic juice, galangal powder and purple potato powder are used as auxiliary materials, the pleurotus eryngii leisure foods are obtained through the steps of cooking, packaging, disinfecting and inspecting. The formula and the making technology disclosed by the invention have the beneficial effects that the pleurotus eryngii leisure foods contain rich nutrient substances, maintain fresh, tender, crisp, smooth, refreshing and tasty leisure flavors, and contain rich element ingredients necessary for human bodies, including iodine, calcium, iron, manganese, magnesium, phosphorus, sodium and zinc, so that the pleurotus eryngii leisure foods guarantee balanced and comprehensive nutrition and palatable flavor, can be instant to eat, are leisure and convenient, are good in eating effect and are beneficial to popularization.

Owner:ZHEJIANG BAIXING FOOD

Kiwi fruit sesame paste

The invention discloses kiwi fruit sesame paste. Kiwi fruits are sliced into thick slices, the thick slices are dried and cut into grains, the dried kiwi grains are rolled into sheets and are evenly mixed with sesame powder and rice flour, and a kiwi fruit sesame paste product which is strong in kiwi fruit flavor, rich in nutrient, easy, convenient and safe to produce, low in energy consumption and more convenient to eat is obtained.

Owner:LUSHAN YINGAN AGRI CO LTD

Royal lotus root egg beancurd and making method thereof

InactiveCN104705695ADark colorReduce colorNatural extract food ingredientsFood ingredient functionsYolkSodium Glutamate

The invention discloses royal lotus root egg beancurd and a making method thereof. The royal lotus root egg beancurd is made of the following raw materials in parts by weight: 70-90 parts of farm eggs, 18-20 parts of royal lotus powder, 0.1-0.3 part of sugar, 0.05-0.15 part of salt, 0.05-0.15 part of sodium glutamate and 0.05-0.15 part of soybean sauce. The making method comprises the following steps: (1) washing, sterilizing, inspecting and breaking to remove shells of the fresh farm eggs, and uniformly stirring egg white and yolk so as to obtain an egg liquid; (2) washing royal lotus roots, removing the rhizoma nelumbinis, smashing to obtain lotus paste, removing lotus dregs, and drying to obtain royal lotus powder; (3) adding water into the royal lotus powder to obtain paste, mixing with the farm egg liquid, adding sugar, salt, sodium glutamate and soybean sauce, uniformly stirring, steaming, and stewing; and (4) drying, packaging, sterilizing, cooling, inspecting, and packaging, thereby obtaining a finished product. As the fresh farm eggs and the royal lotus roots are cooperatively blended to make the royal lotus root egg beancurd, the royal lotus root egg beancurd is rich in nutrition, can nourish weakness of organs, has the effects of tonifying spleen and prompting appetite and smoothening urea and relaxing the bowel, meets the health idea of complementary nutrition and comprehensive balance of modern people, is fine and smooth in taste, and has the advantages of instant taking, convenience in taking, long preservation time and the like.

Owner:ANHUI GUANGLIN EGG PROD

Coarse grain health-preservation breakfast and preparation method thereof

The invention discloses a health-preserving breakfast made of whole grains and a preparation method thereof. 2-3 parts of rice, 1-2 parts of red barley, 0.3-0.5 parts of lotus seeds, 1-2 parts of millet, 0.2-0.4 parts of buckwheat, 0.5-0.6 parts of Gorgon. The health-care breakfast made of whole grains is a finished product through the steps of processing raw materials, baking, mixing, grinding, and packaging. It improves people’s absorption of nutrients. In addition, the final product is powder by adopting baking, milling and other processing methods. It solves the problem that people don't have time to make breakfast due to busy work or other problems.

Owner:池州市知识产权服务中心有限公司

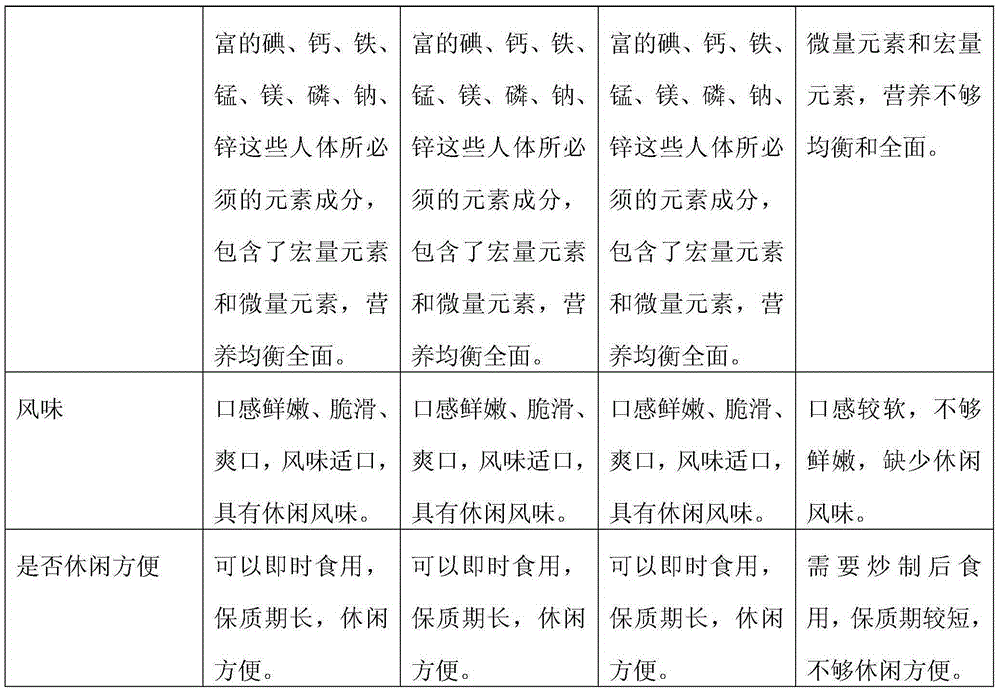

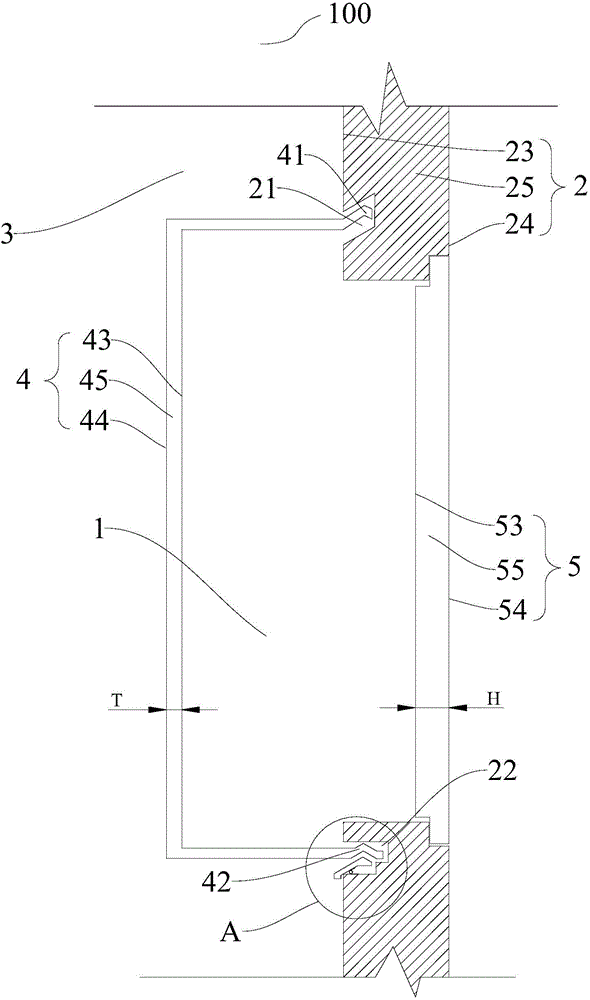

Refrigerator

InactiveCN104654709AEasy to useUse humanizationLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

Owner:HEFEI HUALING CO LTD

Plant pure dew/flower dew swallow nests and preparation method thereof

The invention discloses plant pure dew / flower dew swallow nests and a preparation method thereof. The plant pure dew / flower dew swallow nests are prepared from the following components in parts by weight: 70-80 parts of pure water, 2-5 parts of swallow nests, 0.8-2 parts of pure dew or flower dew and 2-6 parts of white rock candies. The plant pure dew / flower dew swallow nests can be eaten instantly and can be preserved for 24 months if the plant pure dew / flower dew swallow nests are filled by using a dual high-temperature sterile disinfection+dual ultrasonic bottle body sterilization technology; and the plant pure dew / flower dew swallow nests are suitable for people with sick and weak bodies, pregnant women, weak infants, old people, sub-health people with light weight, children and common people.

Owner:王丽芬

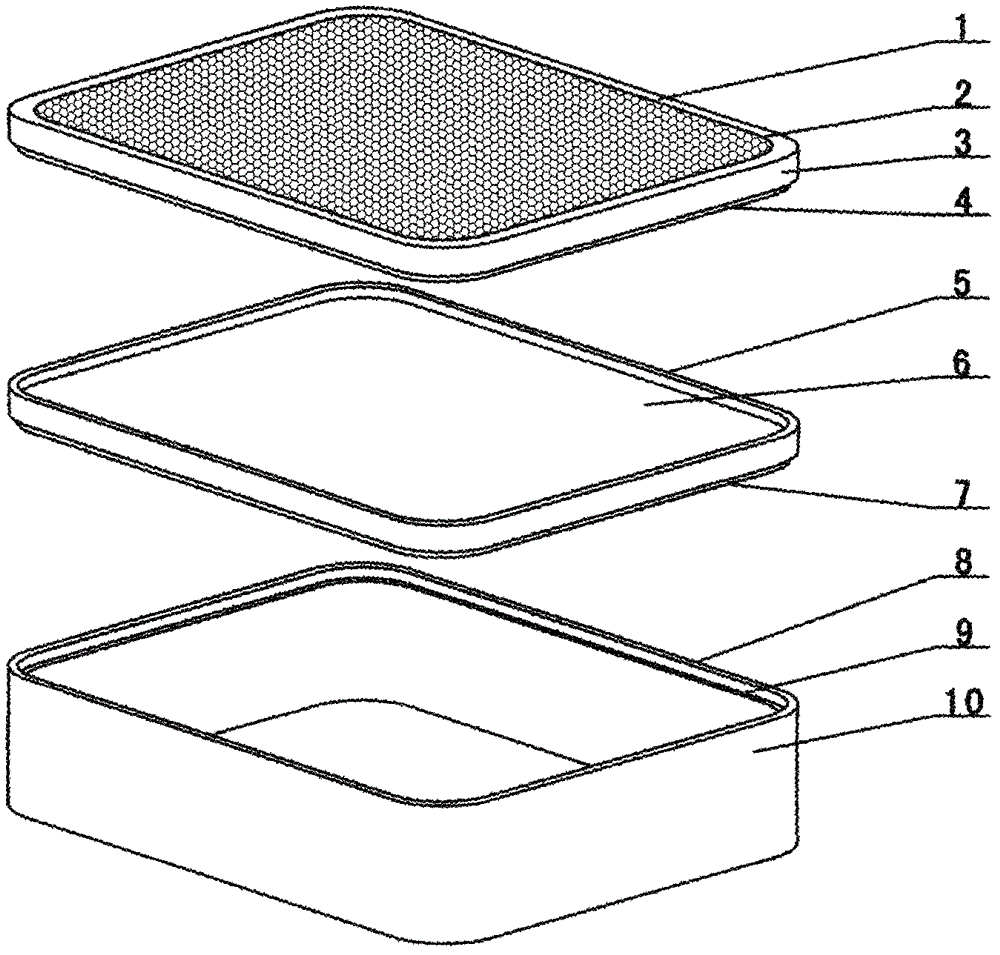

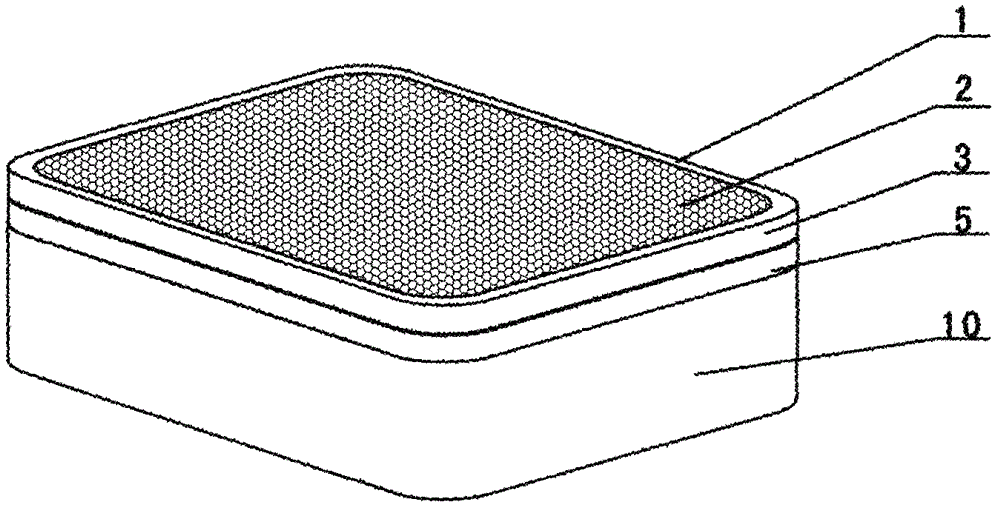

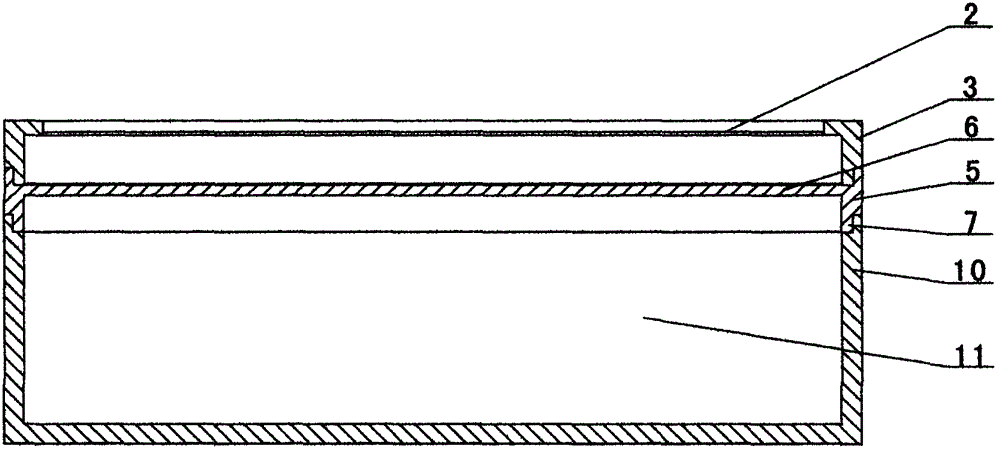

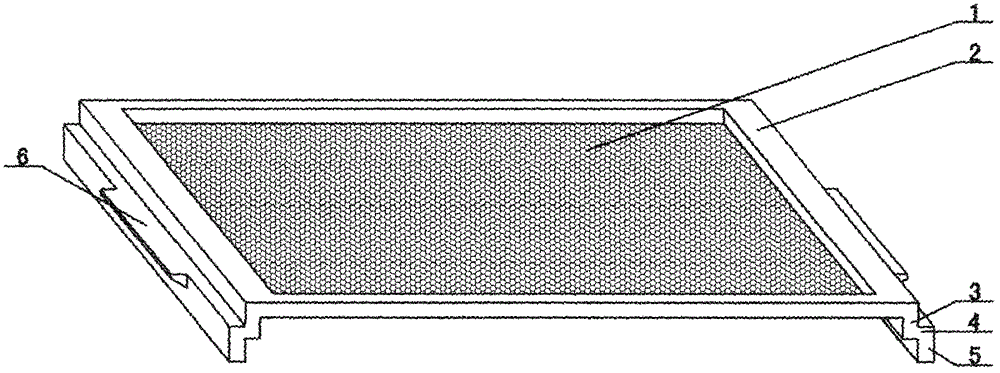

Handmade noodle quick-freezing shelf of refrigerator with storage box

InactiveCN102721254ACool evenlyAchieve storageLighting and heating apparatusSupportQuick FreezeEngineering

The invention discloses a handmade noodle quick-freezing shelf of a refrigerator with a storage box, and relates to a food quick-freezing box for the refrigerator. A supporting disc (3) is of a barrel-shaped structure; the outer edge of a supporting net (2) is fixedly connected with the inner side of an upper part surface (1) on the supporting disc (3); the upper part of a box cover (5) is connected with the lower part of the supporting disc (3) in an inserted way; and the box cover (5) is connected with the upper part of a box body (10) in an inserted way. According to the quick-frozen handmade noodle shelf, the handmade noodles are uniformly cooled through the supporting net, so that the purpose of storing the handmade noodles for long time is achieved; and the handmade noodles are frozen and stored through a special tool provided by the invention, so that the purpose of availability of the handmade noodles at anytime is achieved.

Owner:刘妍君

Liquid food used as meal replacement

InactiveCN105433287AHas the function of meal replacement for hungerIncrease health functionFood ingredient functionsProtein food ingredientsYolkReady to eat

The present invention discloses a liquid food used as meal replacement, and belongs to the field of food and beverage. The liquid food is characterized in that the liquid food is prepared from egg white powder, egg yolk powder, raw materials containing Omega-3 composition, sesame oil, salad oil, antioxidants, stabilizers, fillers, seasonings and water. The liquid food not only meets different needs of the intake of egg yolks, egg white and other nutrient substances for different populations, but also to meets people's need of Omega-3 intake. Lecithin of the egg yolks also emulsifies the raw materials containing Omega-3 composition and other oils, which is conducive to digestion and absorption of nutrient substances including Omega-3. The liquid food not only has hunger-allaying and meal-replacing functions, but also has a variety of excellent health-care functions, achieving a dual-use effect of edible property and disease prevention. The liquid food has ready-to-eat property, and meets needs of the fast-paced life way.

Owner:刘福敏

Handmade noodle quick-freezing plate for refrigerator

InactiveCN102721253ASimple structureAchieve storageLighting and heating apparatusSupportEngineeringRefrigerated temperature

Owner:慈溪市附海镇界诺电器厂

Chicken jerky and preparation method thereof

InactiveCN103462064BSoft textureChange the characteristics without dietary fiberFood preparationCooking & bakingFruit juice

The invention discloses a chicken breast and a preparation method thereof, which belongs to the technical field of food processing. The chicken breast uses chicken, fruit and vegetable residues and oats as main raw materials. It is first put into a freezer for freezing and marinating, and then baked and grilled. The juice is sprayed on the surface of the semi-finished product to obtain the finished product. The method of the invention is simple and easy to operate, fully preserves the nutritional components of the chicken, and effectively combines the nutritional components of fruits, vegetables and oats, and uses a special baking process to effectively prevent the nutritional components and activity of the chicken. The ingredients are lost and destroyed, and a unique composite flavor of fruit, vegetable and chicken is formed, with good taste and smooth and seamless appearance. The obtained product can be eaten immediately and can be used as snacks and other snacks, or as low-fat, low-calorie food for the elderly.

Owner:KUNMING UNIV OF SCI & TECH

Pet cage for veterinarian caring

ActiveCN108635077ANormal physiological activityReady to eatAnimal watering devicesAnimal feeding devicesEngineeringDigestion

The invention relates to a pet cage, and in particular to a pet cage for veterinarian caring. The invention aims at providing the pet cage for veterinarian caring, which is capable of conducting grinding treatment on large pet food grains and is capable of effectively masking odor from pets. According to the technical scheme, the pet cage for veterinarian caring comprises a first mounting plate, awater frame, a second mounting plate, first supporting rods, a box, a meshed plate, a hinge, a cover plate, a pull handle and the like, wherein the water frame is arranged at the left side of the topof the first mounting plate; the second mounting plate is arranged at the top of the first mounting plate at the left side of the water frame; and the first supporting rods are arranged on upper partof the right side of the second mounting plate in a longitudinal symmetry mode. According to the pet cage provided by the invention, large pet food grains can be ground, so that rapid digestion of the grains which are eaten by pets is promoted, and energy extracting efficiency is indirectly improved; and along with rotation of blades, circulation of surrounding air can be accelerated, so that intense dispersion of fragrance can be promoted to effectively mask odor from the pets.

Owner:库俊红 +2

Preparation method of instant dendrobium officinale

InactiveCN107198229AReady to eatImprove the level of science and technologyFood sciencePreservativeEconomic benefits

The invention discloses a preparation method of instant dendrobium officinale. The method comprises the following steps of cleaning, draining, drying, boiling, draining, packaging, sterilization and cooling. The preparation method of the instant dendrobium officinale provided by the invention has the advantages that the instant eating of the dendrobium officinale product is realized; under the condition of not adding additives such as preservatives, the storage time is long; safety and reliability are realized; the eating is convenient; the scientific and technical level of the Chinese dendrobium officinale deep processing industry is improved; the economic benefits of enterprises are greatly improved; a novel application mode is provided for the large scale production and sales of the dendrobium officinale.

Owner:JIANGSU FENGGU BIOLOGICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com