Original instant lanceleaf lily bulb crisp processing method

A processing method and technology of lily, which is applied in the processing field of original flavor instant lily chips, can solve problems such as unsuitable for consumption, loss of nutritional components of lily, high hardness of lily products, etc., to achieve increased added value and market competitiveness, good sensory quality, Add new types of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take the lily of Lanzhou geographical indication product, wash, remove stains and sediment; split the petals, and remove the lily petals with incomplete appearance, corruption and yellowing parts to obtain the raw lily; place the raw lily in an environment with a temperature of 95°C for 7 minutes, The raw material lily is matured to obtain cured lily; the matured lily is pre-frozen in an environment with a temperature of -20°C for 8 hours; it is dried in a cold trap with a temperature of -42°C and an air pressure of 13Pa for 15 hours to obtain the original flavor of instant lily chips. The moisture content of the lily chips is 8%.

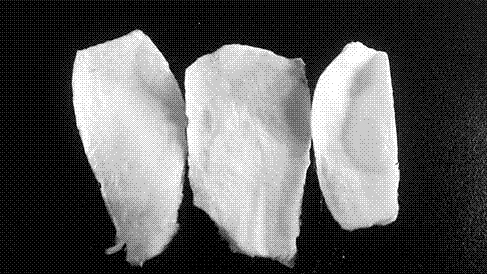

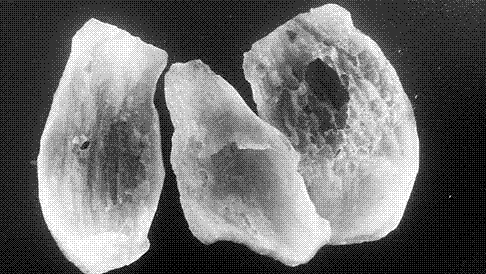

[0028] The physical figure of the lily crisp sheet that embodiment 1 makes, as figure 1 , It can be seen from the picture that the color of the lily is white and complete, the flesh is thick and free of impurities, basically maintaining the original color of the lily. After tasting, the taste is delicate and crisp, and the taste is better. ...

Embodiment 2

[0030] Take the lily that is a geographical indication product of Lanzhou, wash it, remove stains and sand, separate the petals, and remove the lily petals with incomplete appearance, corruption and yellowing parts to obtain the raw lily; The raw material lily is matured to obtain matured lily; the matured lily is pre-frozen in an environment with a temperature of -25°C for 5 hours, and then dried in a cold trap with a temperature of -44°C and an air pressure of 12Pa for 12 hours to obtain the original flavor instant lily crisp. The moisture content of the chips is 3%.

Embodiment 3

[0032] Take the lily lily which is a geographical indication product of Lanzhou, wash it, remove stains and sediment, split the petals, and remove the lily petals with incomplete appearance, corruption and yellowing parts to obtain the raw lily; place the raw lily in an environment with a temperature of 97°C for 6 minutes, and make The raw material lily is matured to obtain cured lily; the matured lily is pre-frozen in an environment with a temperature of -23°C for 7 hours, and then dried in a cold trap with a temperature of -43°C and an air pressure of 13Pa for 13.5 hours to obtain the original flavor of instant lily chips. The moisture content of the lily chips is 5.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com