Sausage made of meat from spareribs and its making process

A production method and technology for ribs, which are applied in the field of food and meat processing, can solve the problem of no ribs and sausages, and achieve the effects of prolonging storage time, simple and reasonable method, and improving product flavor and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

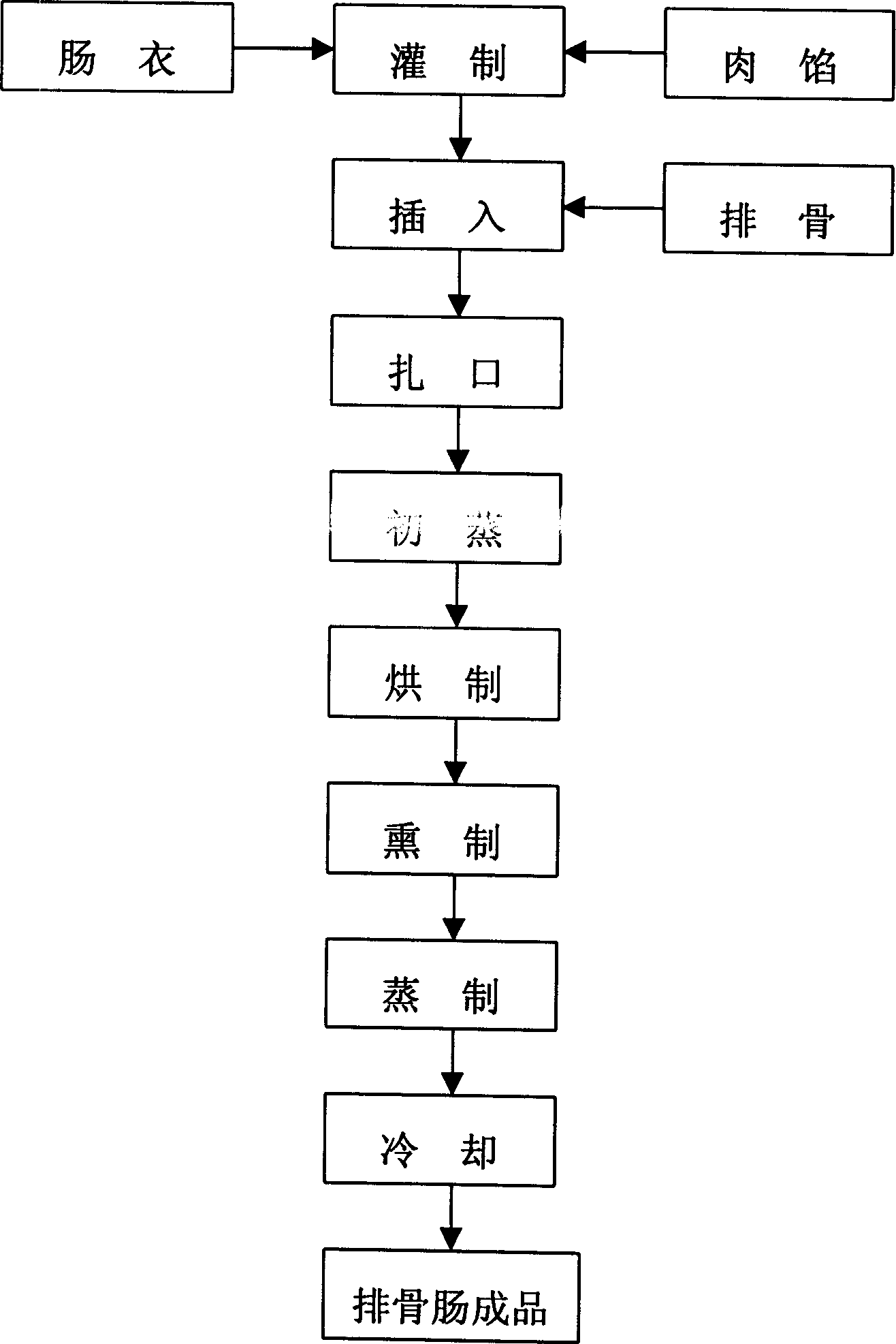

[0018] As shown in the attached picture of the manual, make the minced meat, pour the minced meat into the casing, and the filling amount is 50% of the capacity of the casing; arrange the raw pork ribs, add seasonings, stir, marinate, and then insert the ribs into the casing Inside the casing with 50% meat stuffing, the casing is tied, steamed, baked, smoked, steamed, and cooled to make ribs sausage. According to the above, the lamb ribs, beef ribs, rabbit ribs, and chicken leg bones were used to make them respectively, and all received expected good results. According to the above, the production of collagen casings and natural casings also received expected good results. According to the above, it is made with plastic casings without baking or smoking, and the expected good results are all received.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com