Polyamide yarn and viscose staple yarn twisted composite yarns and preparation method thereof

The technology of fiber yarn and spun fiber yarn is applied in the field of composite yarn and its preparation, which can solve the problems of complex production steps, thick bead yarn and high production cost, and achieve excellent hygroscopicity, good resilience and good elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

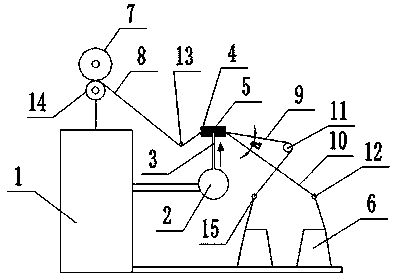

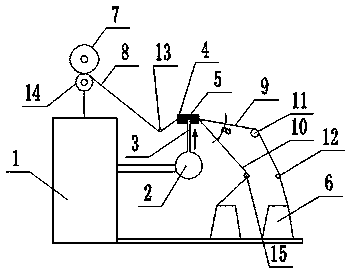

Method used

Image

Examples

Embodiment 1~ Embodiment 3

[0036] The composite yarn of nylon filaments twisted with viscose staple yarns in the present invention is made of viscose staple yarns and nylon filaments. The existing nylon filaments twisted with viscose staple yarns The composite yarn is made of viscose filament yarn. The components of the two are different, and in the preparation method at the same time, the composite yarn of the nylon filament twisted viscose spun yarn described in the present invention obtains better performance through a specific preparation method, and obtains excellent hygroscopicity, drapability, etc. Better, better resilience, better wearability, better elasticity composite yarn of nylon filaments twisted with viscose staple yarn.

[0037] Table 1 shows the composite yarns of nylon filaments twisted with viscose short fiber yarns according to the present invention and the composite yarns of existing nylon filaments twisted with viscose long fiber yarns (No. 4, 5 and 6), existing Comparison of perf...

Embodiment 4

[0043] A composite yarn of nylon filaments twisted with viscose spun yarns, the composition content of which is 60-70% of viscose staple yarns and 30-40% of nylon filaments; the nylon filaments twisted with viscose The hundred-meter weight of the composite yarn of spun yarn is 3.5~4g; The single yarn breaking strength of the composite yarn of the twisted viscose staple yarn of the nylon filament is 900~1000cN; The twist of the composite yarn combined with the viscose spun yarn is 580-630.

[0044] In the composite yarn of nylon filament twisted viscose staple fiber yarn of the present invention, its preparation method comprises the following steps:

[0045] A. The viscose staple yarn is mixed with nylon filaments by air-flow net joint strands to form segmental joints, which increases the yarn strength and has a certain degree of elasticity.

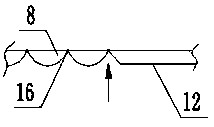

[0046] B. The two mixed yarns are twisted separately and then ply twisted to form a composite yarn in which bead-shaped hollow nylon fi...

Embodiment 5

[0051] The invention discloses a composite yarn of nylon sliver twisted with viscose spun yarn, and its component content is 60% of viscose spun yarn and 40% of nylon sliver.

[0052] The dry breaking strength of the viscose staple yarn of the present invention is greater than 3.2N / tex; the wet elongation of the viscose staple yarn is 18%; the wet breaking strength of the viscose staple yarn is greater than 1.6N / tex; the elongation at break of the viscose staple yarn is 12%; the cut length of the viscose staple yarn is 32 mm; the fineness of the viscose staple yarn is 0.7dtex .

[0053] The melting point of the nylon thread of the present invention is 210 DEG C; the melting index of the nylon thread is 60g / 10min; the denier of the nylon thread is 30D.

[0054] The linear density of the viscose spun yarn in the present invention is 10Tex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com