Linked color adjusting and flavor adjusting device and method for preparing plant protein meat

A vegetable protein meat and pigment technology, applied in chemical instruments and methods, mixers with rotating stirring devices, applications, etc., can solve the problems of cumbersome process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

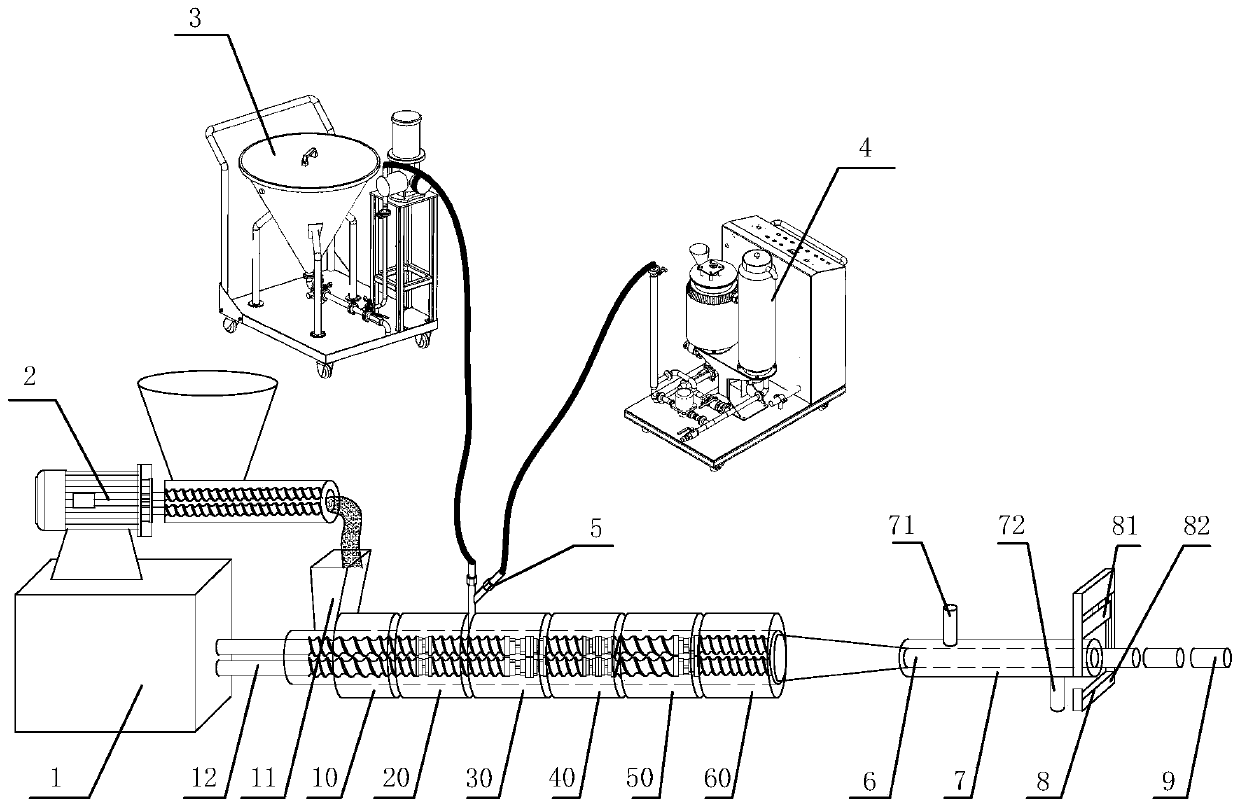

[0075] A method for linkage coloring and seasoning for preparing vegetable protein meat, comprising the following steps:

[0076] (1) Mixing of raw materials: Mix about 3 kg of vegetable protein raw materials, including peanut protein, soybean protein and wheat protein, and place them in the solid feeder 2 .

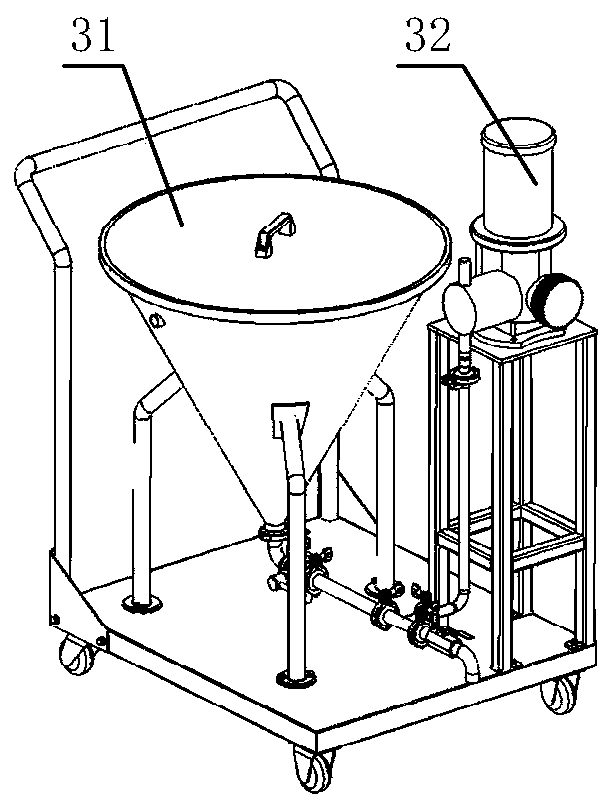

[0077] (2) Toning and seasoning liquid preparation: put water in the first liquid feeder 3;

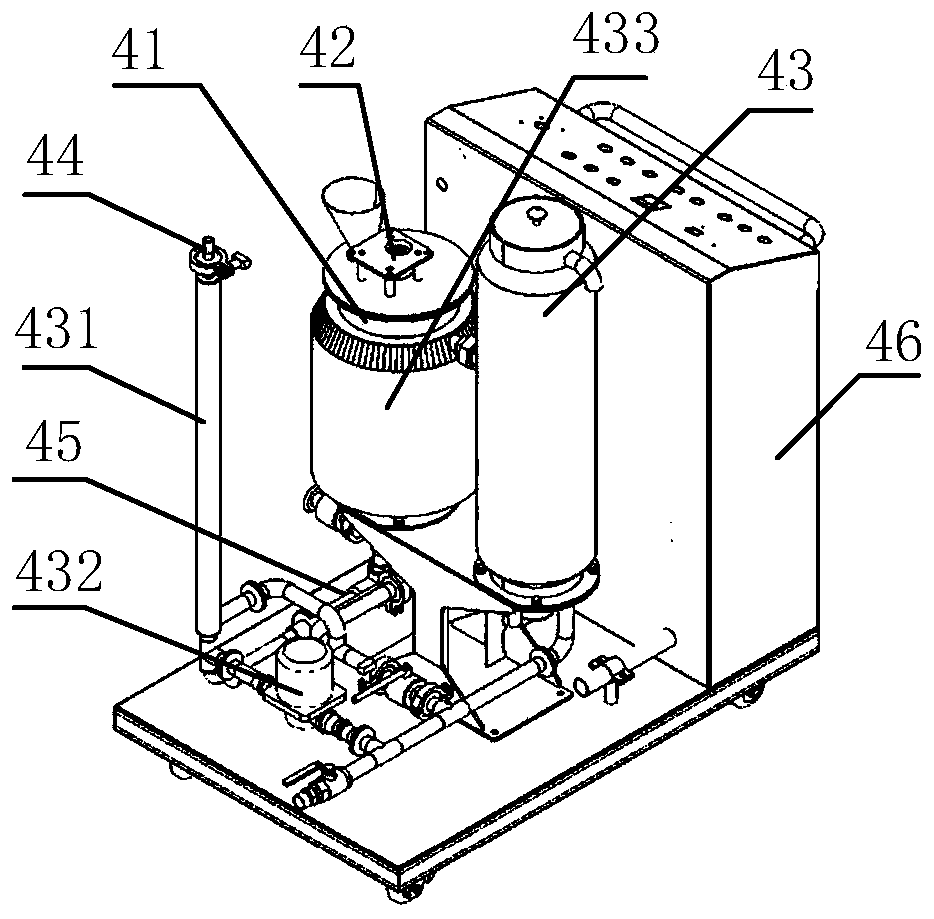

[0078] (3) Equipment assembly: put the assembled screw rod 12 into the barrel of the twin-screw extruder 1, and connect the molding die 6 with the barrel; connect the solid feeder 2, the first liquid feeder 3, The second liquid feeder 4 and the three-way joint 5 are connected with the barrel of the twin-screw extruder 1 through threads.

[0079] (4) Preheating: preheating the barrel of the twin-screw extruder 1 and the molding die 6 .

[0080] (5) Extrusion molding: Simultaneously open the twin-screw extruder 1, the solid feeder 2, the first liquid feeder 3 and the second liqu...

Embodiment 2

[0085] A linkage coloring and seasoning method for preparing vegetable protein meat, the specific operation steps are the same as in Example 1, the only difference is that the powder flow rate of the solid feeder 2 in step (5) is 12kg / h.

[0086] The vegetable protein meat organoleptic quality that the present embodiment makes is as follows:

[0087]

Embodiment 3

[0089] A kind of linkage coloring seasoning method for preparing vegetable protein meat, the specific operation steps are the same as embodiment 1, the only difference is: in step (5), the flow rate of the first liquid feeder 3 is the same as that of the solid feeder 2 The powder material flow rate ratio is 110%.

[0090] The vegetable protein meat organoleptic quality that the present embodiment makes is as follows:

[0091]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com