Steel rolling roller way deduster

A dust collector and roller table technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of large investment, dirty and chaotic environment around the production site, and many equipment required, and achieve high efficiency, Easy and flexible assembly, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

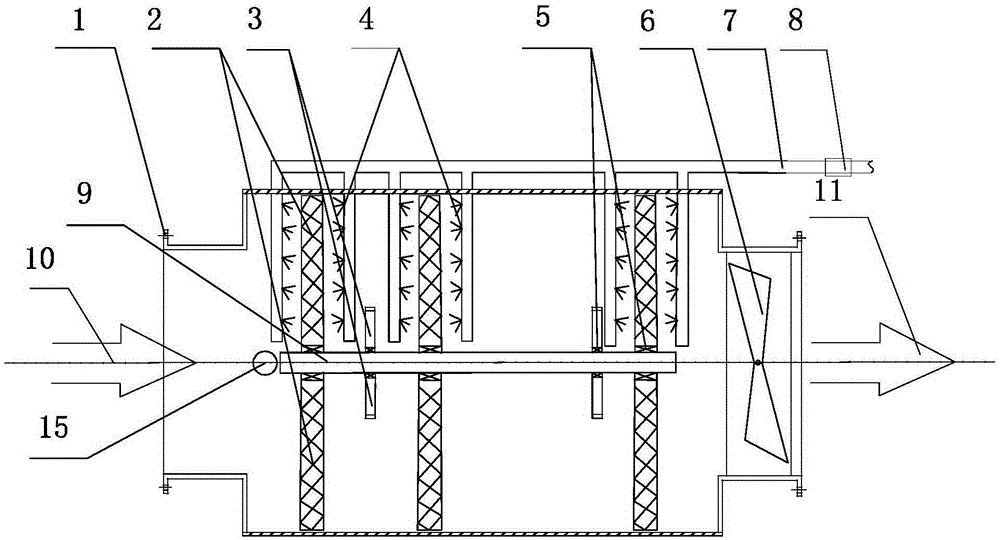

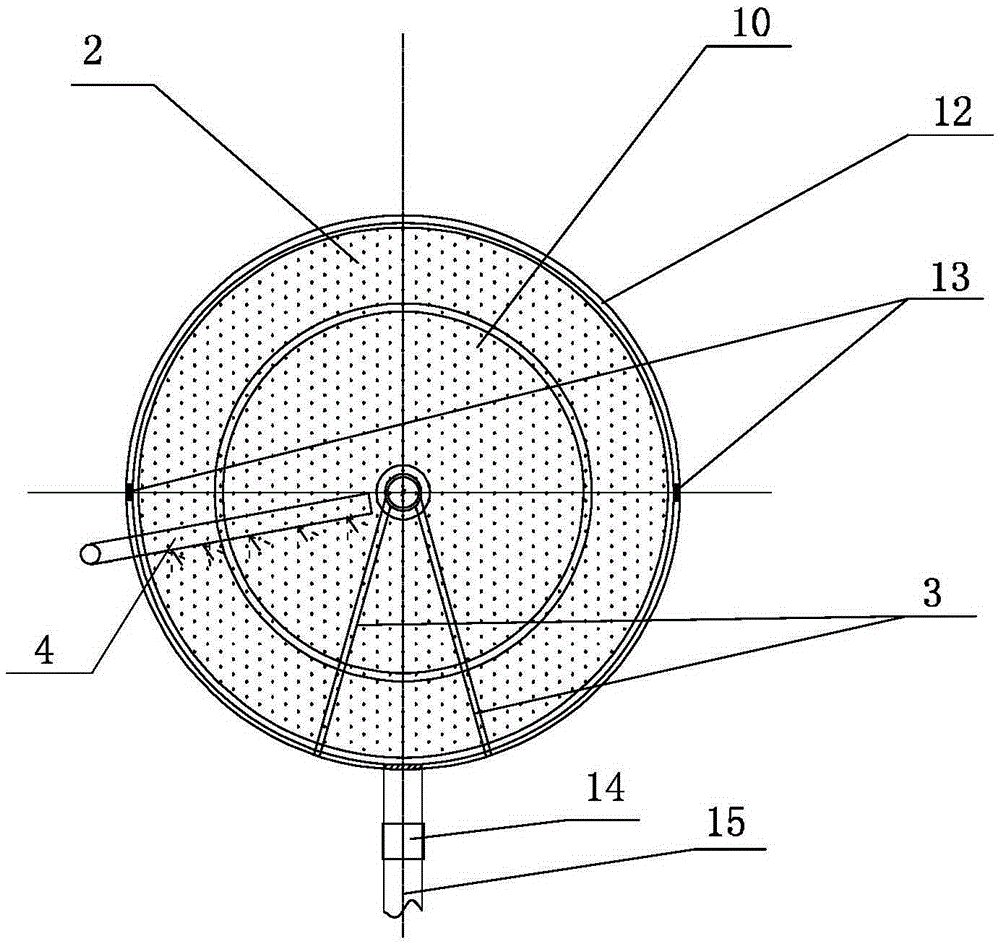

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] The specific structure is as figure 1 , figure 2 As shown, a steel rolling roller table dust collector, its shell is a horizontal cylinder 12 as a whole, one end of the cylinder 12 is a smoke inlet 10, and the other end of the cylinder 12 is a fresh air outlet 11. The housing has a smoke inlet section, a smoke filter section and an air output section connected in sequence. In order to facilitate the connection of the casing with the dust collector and the exhaust pipe and improve the dust removal efficiency, the inner diameters of the dust inlet section and the air output section are smaller than the inner diameters of the dust filter section. exist figure 1 Among them, the left end of the smoke and dust entry section is the smoke and dust inlet 10, and the right end of the air output section is the fresh air outlet 11. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com