Sheet material curved surface forming stamping die

A surface forming and stamping die technology, applied in the field of sheet surface forming stamping die, can solve the problems of complex processing, low efficiency of production methods and high production cost, and achieve the effects of reducing production cost, simplifying processing complexity and simplifying processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

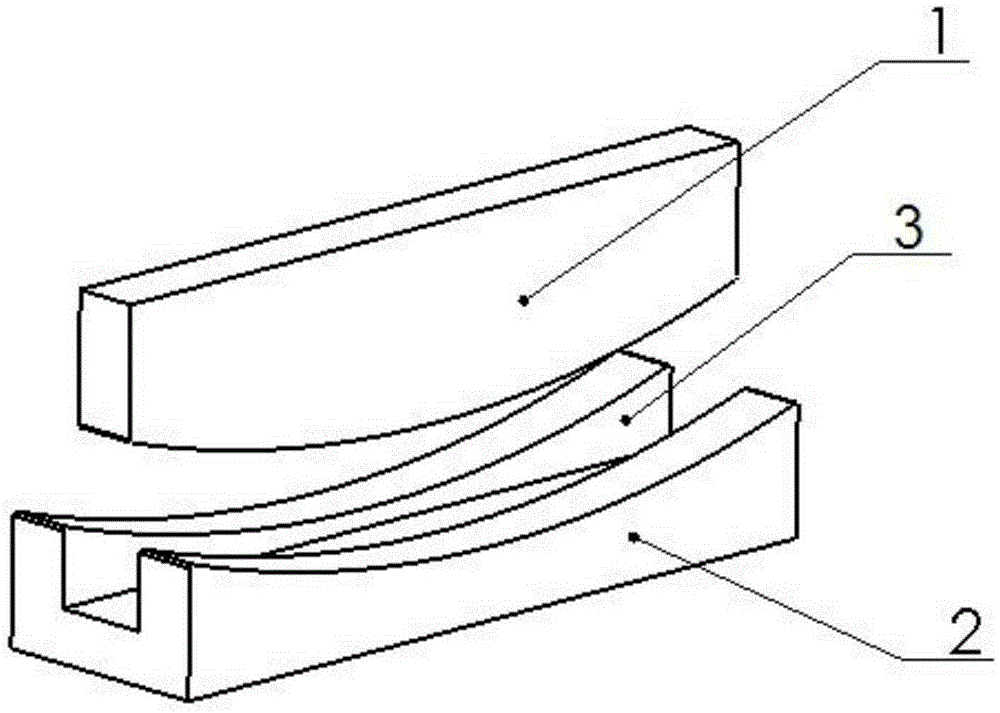

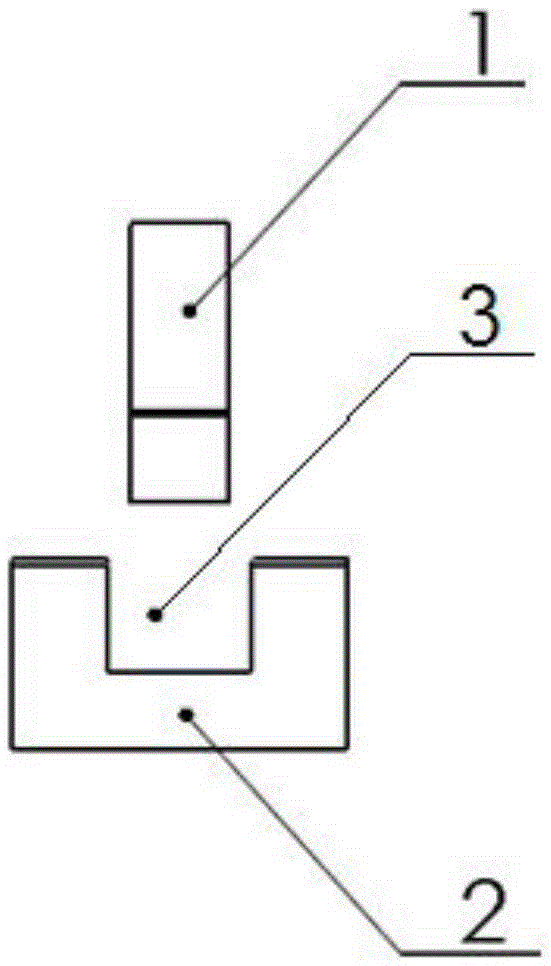

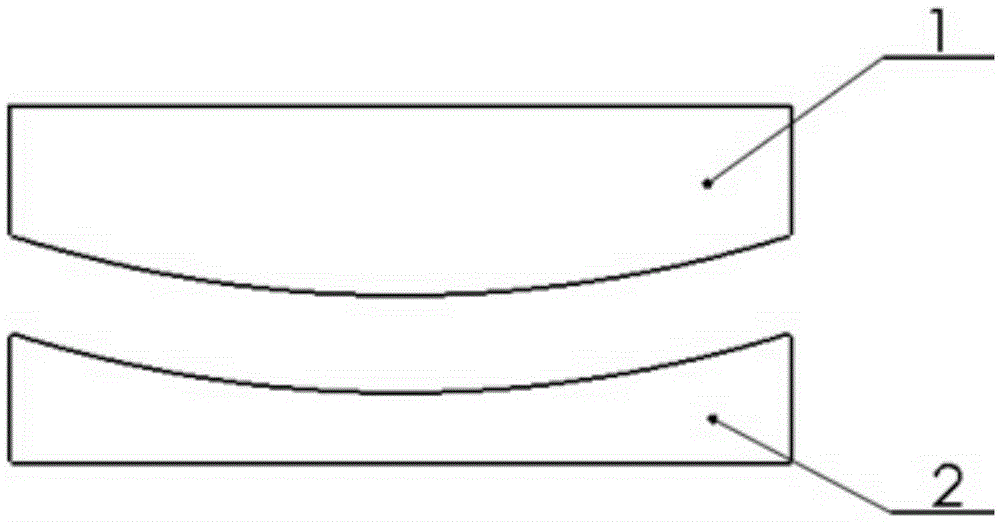

[0018] as attached figure 1 to attach image 3 As shown, the present invention provides a sheet metal curved surface forming stamping die, including a punch 1 and a die 2, the punch 1 is located above the die 2, and the punching surfaces of the punch 1 and the die 2 are curved On the surface, the stamping surfaces of the punch 1 and the die 2 mesh with each other, the die 2 is provided with a groove 3 along the transverse direction, the thickness of the punch 1 is smaller than the groove width of the groove 3, and the width of the punch 1 and the die 2 is the same , the die 2 is fixed, and the punch 1 moves longitudinally.

[0019] The stamping method of the sheet material curved surface forming stamping die includes the following steps: fixing the die 2 on the operating platform, placing the sheet material workpiece between the punch 1 and the die 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com