Ultrasonic washing type sand removal head of casting mold

A casting mold and ultrasonic technology, applied in the field of casting mold cleaning, can solve the problems of increased production cost, damage to sanding holes, high labor intensity, etc., and achieve the effects of improving efficiency, avoiding damage, and safe sand falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

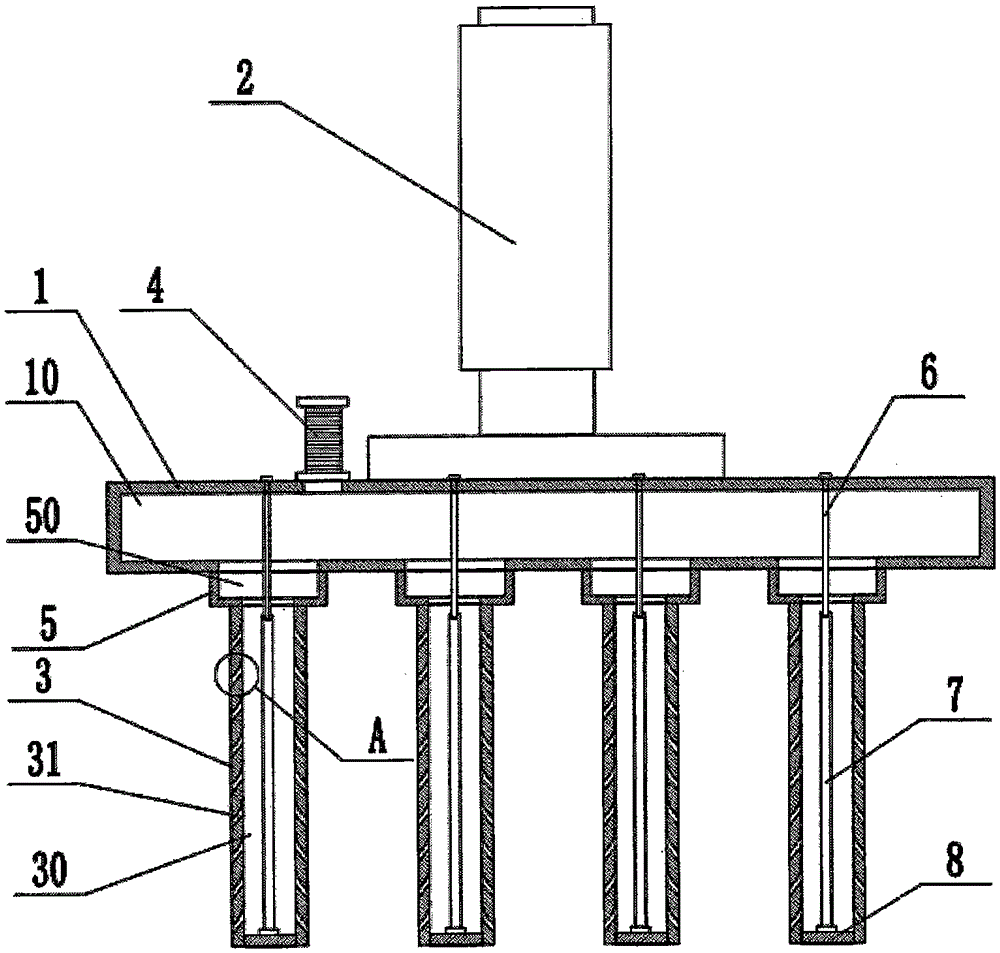

[0017] like figure 1 As shown, the ultrasonic water washing sand removal head of the casting mold of the present embodiment includes a fixed seat 1, a lifting cylinder 2 is installed on the upper surface of the fixed seat 1, and a plurality of top cores 3 are installed on its lower surface, and the position of the top core 3 Corresponding to the position of the sand shooting hole, the fixed seat 1 is a hollow structure with an inner cavity 10, and its upper surface is installed with a water inlet pipe 4 communicating with the inner cavity 10; the top core 3 is a hollow tube with a water guide channel 30 structure, its side wall has a plurality of jet holes 31 connected to the water guide channel 30 and arranged up and down, the jet holes 31 are arranged obliquely downward relative to the central axis of the top core 3, and an ultrasonic generating tube is installed in the water guide channel 30. The generating tube includes a launch end 6 and an introduction end 7. The launch ...

Embodiment 2

[0020] like figure 1 As shown, the ultrasonic water washing type desanding head of the casting mold of this embodiment, compared with the improvement of the first embodiment, the top core 3 is fixedly connected with the fixing seat 1 through the installation head 5, and the installation head 5 has a communication inner cavity 10 and The water passage cavity 50 of the water guide channel 30 has an inner diameter larger than that of the water guide channel 30 . The water passage 50 transitions to the water guide channel 30 , forming a constricted structure as a whole, which increases the water pressure of the water guide channel 30 , thereby increasing the injection pressure of the jet hole 31 .

Embodiment 3

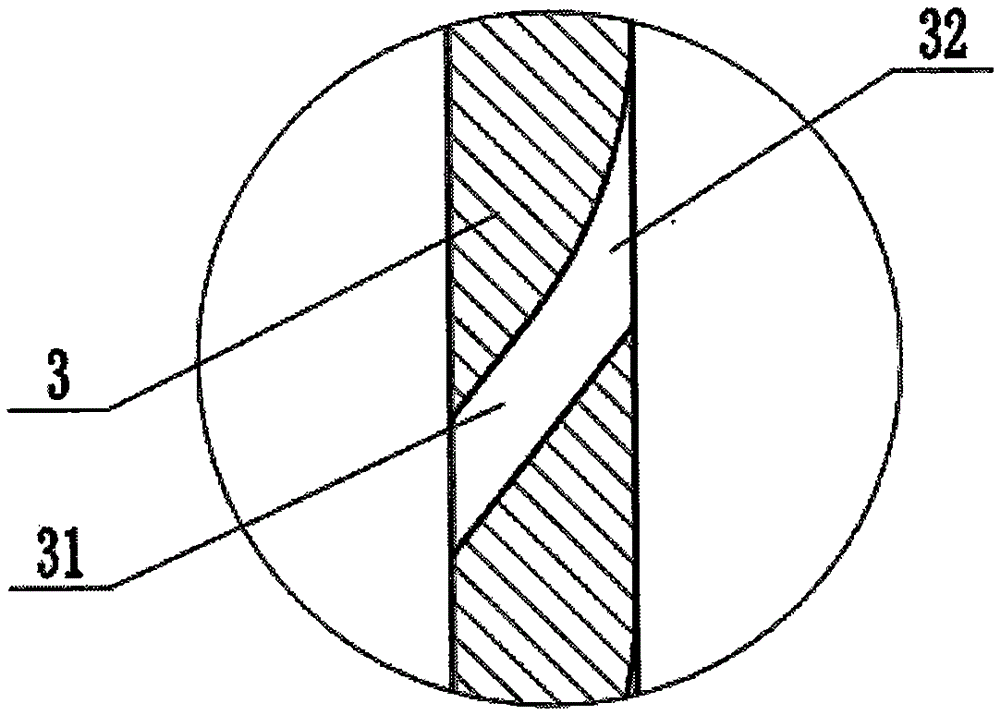

[0022] like figure 1 , figure 2 As shown, the ultrasonic water washing sand removal head of the casting mold in this embodiment is improved compared with the first embodiment in that the inner end of the jet hole 31 has a flared mouth 32 in the shape of a trumpet. The trumpet shape of the flaring mouth 32 facilitates the flow of water into the jet hole 31 and reduces the injection resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com