A wire-electrode cutting discharging processing machine with a processing information management function

A discharge processing machine and management function technology, applied to metal processing equipment, electric processing equipment, circuits, etc., can solve problems such as confusion at the processing site, inability to manage processing information, troublesome product settings, etc., and achieve simple management and shorten processing time. The effect of preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

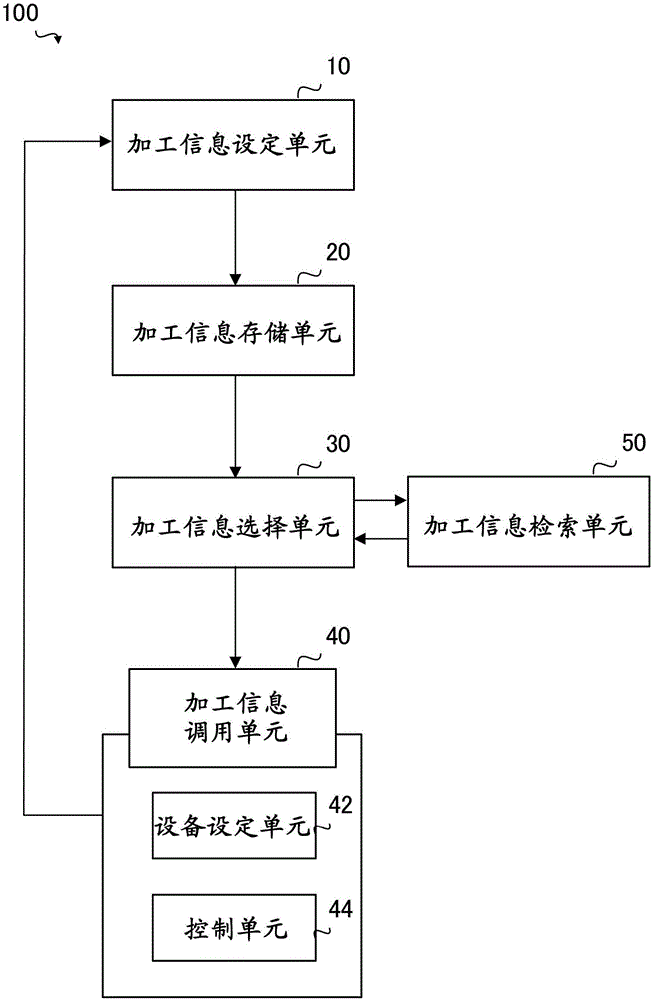

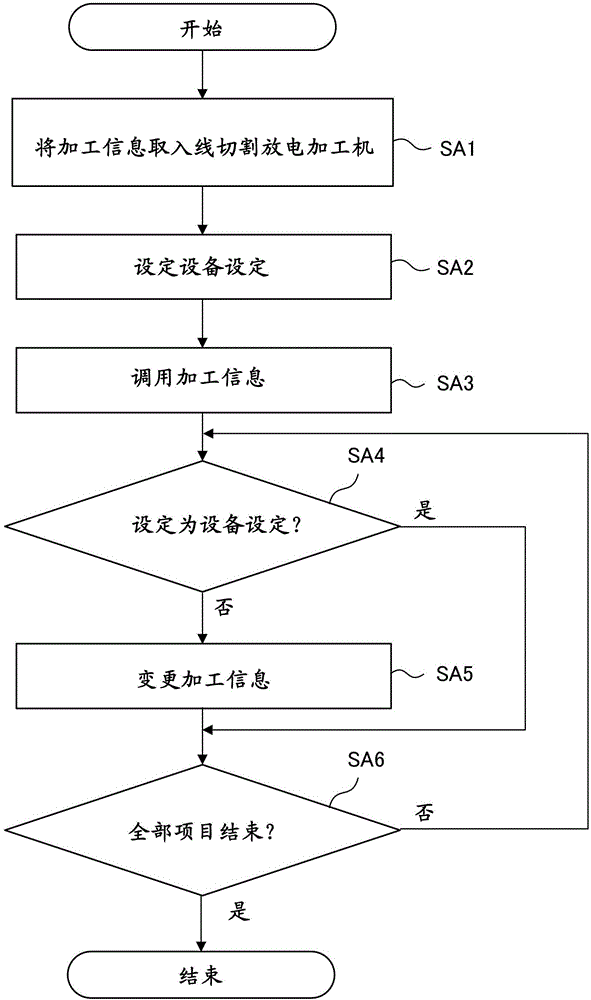

[0043] In this embodiment, a specific example of changing the processing information while maintaining the device settings will be described.

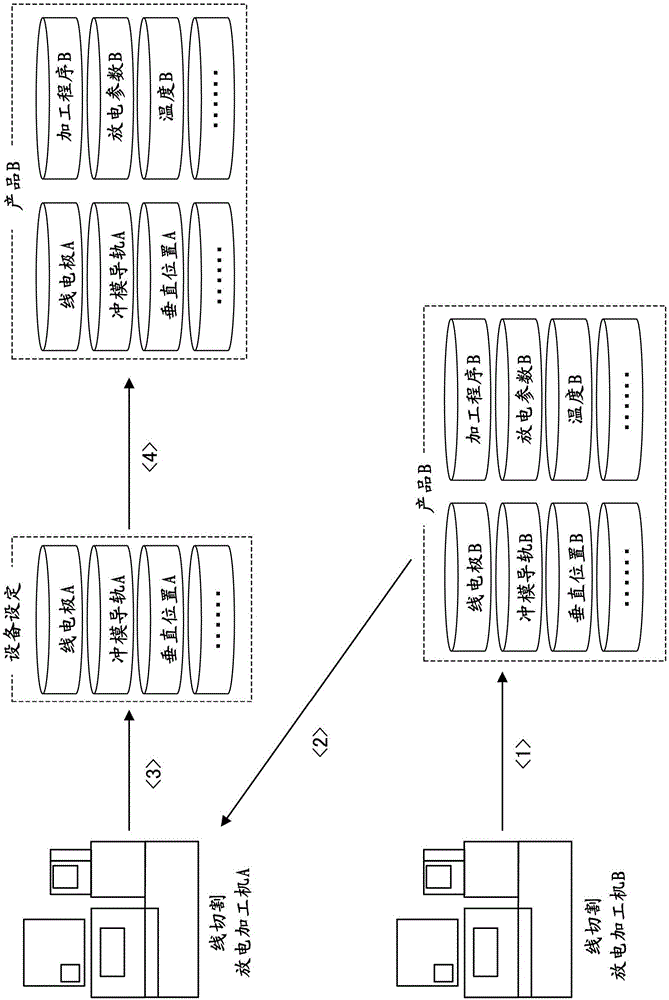

[0044] In this embodiment, as figure 1 As shown, first of all, Processing product B, storing processing information. Specifically, when the product B is processed by the wire-cut electrical discharge machine B, the processing information setting unit 10 sets the processing program B, the wire electrode B, the die guide B, the vertical position B and other processing information, and stores them in the machine In the processing information storage unit 20 composed of a storage area and an external memory.

[0045] then, In the case of processing the product B by the wire-cut electric discharge machine A, The processing information of the product B in the processing information storage unit 20 of the wire-cut electrical discharge machine B stored by the external memory and communication unit is referred to, and the processing information ...

no. 2 approach

[0057] In this embodiment, according to Figure 4 , 5 In the case of processing the same type of product, an example of selecting processing information items other than the equipment setting and changing as needed is described.

[0058] Such as Figure 4 As shown, in the case of processing a certain product A, the processing program A, wire electrode diameter A, workpiece material A, and rail type A are set by the processing information setting unit 10 and stored in the processing information storage unit 20.

[0059] Then, in the case of processing the stored product A, such as Figure 5 As shown, the processing information is retrieved by the processing information retrieval unit 50 based on the identification number such as the product name set when it was previously stored in the processing information storage unit 20, and the retrieved processing information is selected by the processing information selection unit 30 according to site needs as necessary Project, so the stored ...

no. 3 approach

[0071] In this embodiment, an example of restoring to the state before the processing information is changed will be described.

[0072] Such as Figure 7 As shown, in the case of processing product A with processing information stored, the processing information of product A is retrieved and called, and the processing information currently set in the online cutting electric discharge machine is stored in the temporary storage area of the processing information storage unit 20 in. Then, after the processing of the product A is completed, according to the operation of the operator, the existing processing information is called from the temporary storage area as necessary to set it, so that the state after the processing information is changed can be restored to the original state.

[0073] By configuring such a function, it is possible to easily return to the previous processing information setting state, and it can be effective for recovery in the case of a setting error, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com