Milling rapid reloading fixture for servo valve shell parts

A technology for milling and servo valves, which is applied in the field of fast-changing fixtures for the milling of servo valve housing parts, can solve the problems of cumbersome process, long and complicated processing preparation time, and achieve the goal of improving operation efficiency and reducing processing preparation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

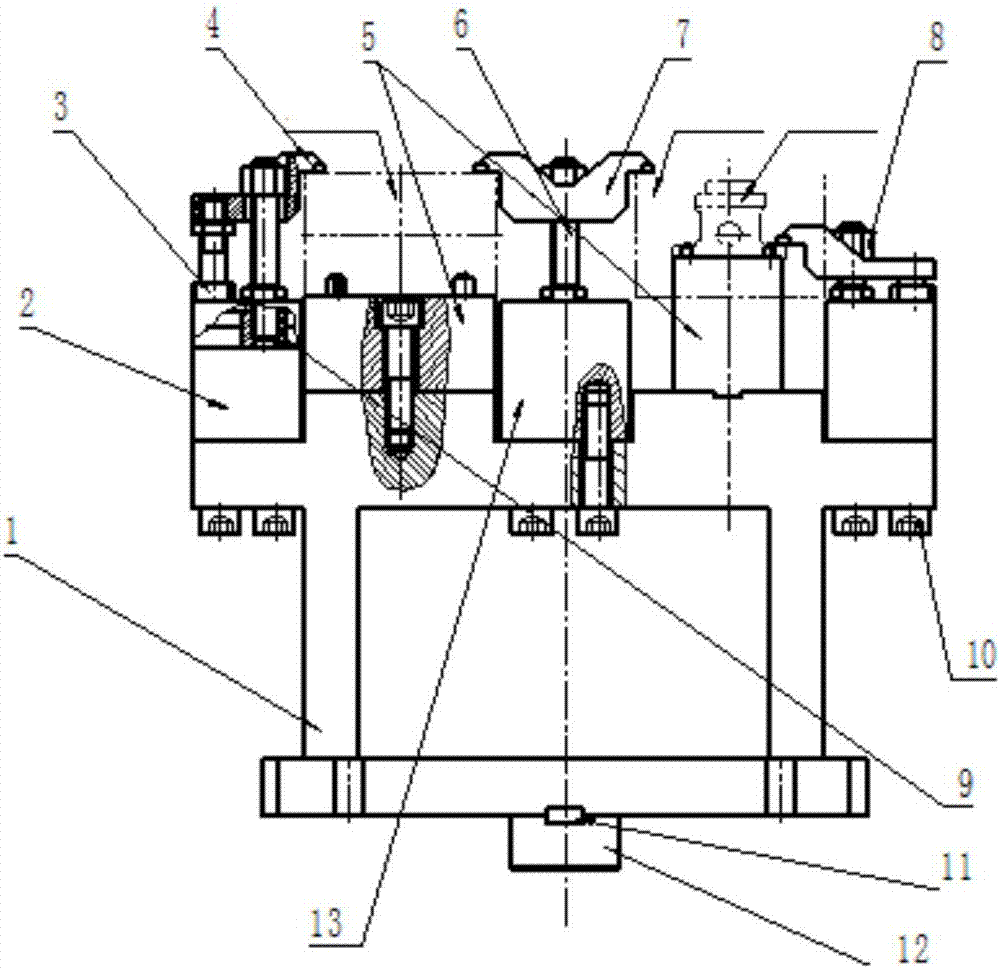

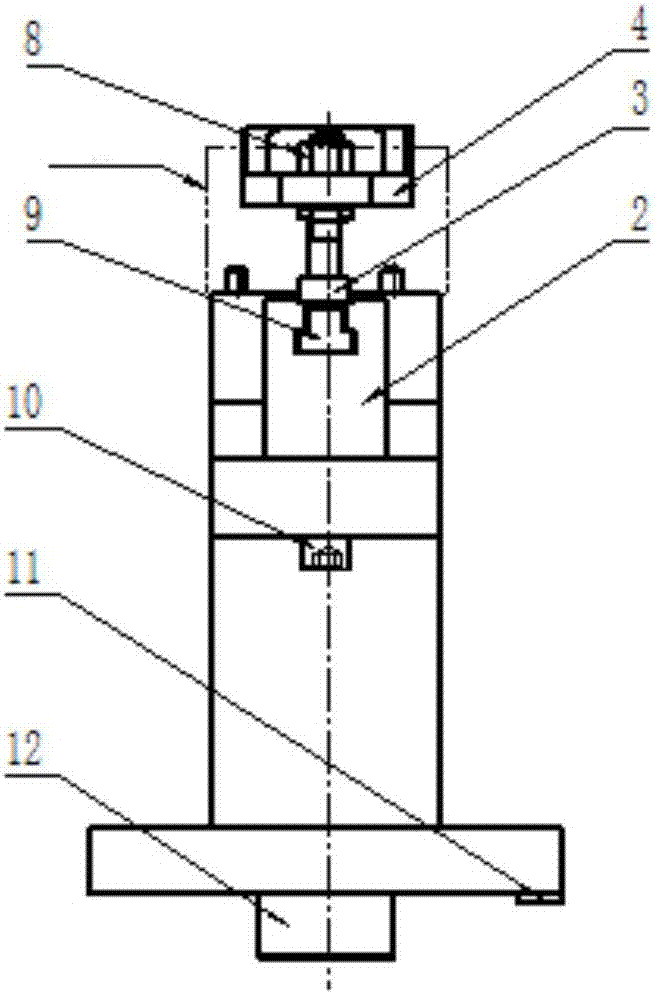

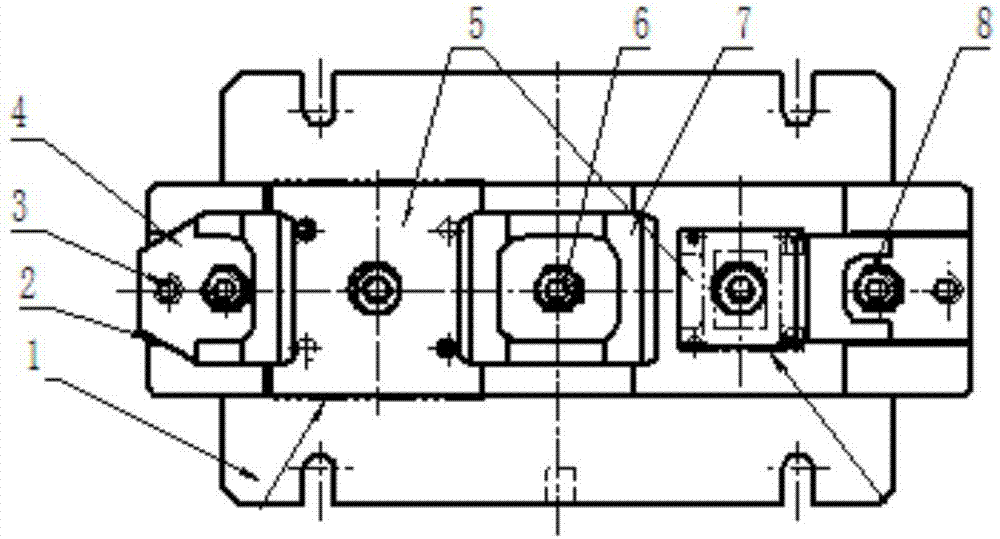

[0016] A quick change jig for milling of servo valve housing parts provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a quick change fixture for milling of servo valve housing parts, including a base frame 1, a connecting block 1, a series of support nails 3, a series of pressure plates 4, a series of positioning blocks 5, a series of screws 6, Series of double-head pressure plate 7, nut 8, T-nut 9, screw 10, positioning key 11, positioning shaft 12, connecting block 2 13;

[0018] The base frame 1 is fixedly connected with the machine tool table through the positioning key 11 and the positioning shaft 12. There are 4 open long slots at the four corners of the base frame 1, and fastening screws can be installed to fasten the fixture to the bed surface;

[0019] Connecting block 2 13 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com