Machining device for space deep inclined holes in large wind power box

A processing device and wind power technology, which is applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problems of large-scale pentahedron machining centers with complex structures, high requirements for operators, and high input-output ratio, and achieve The effect of simple structure, reduced completion time, and low input and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

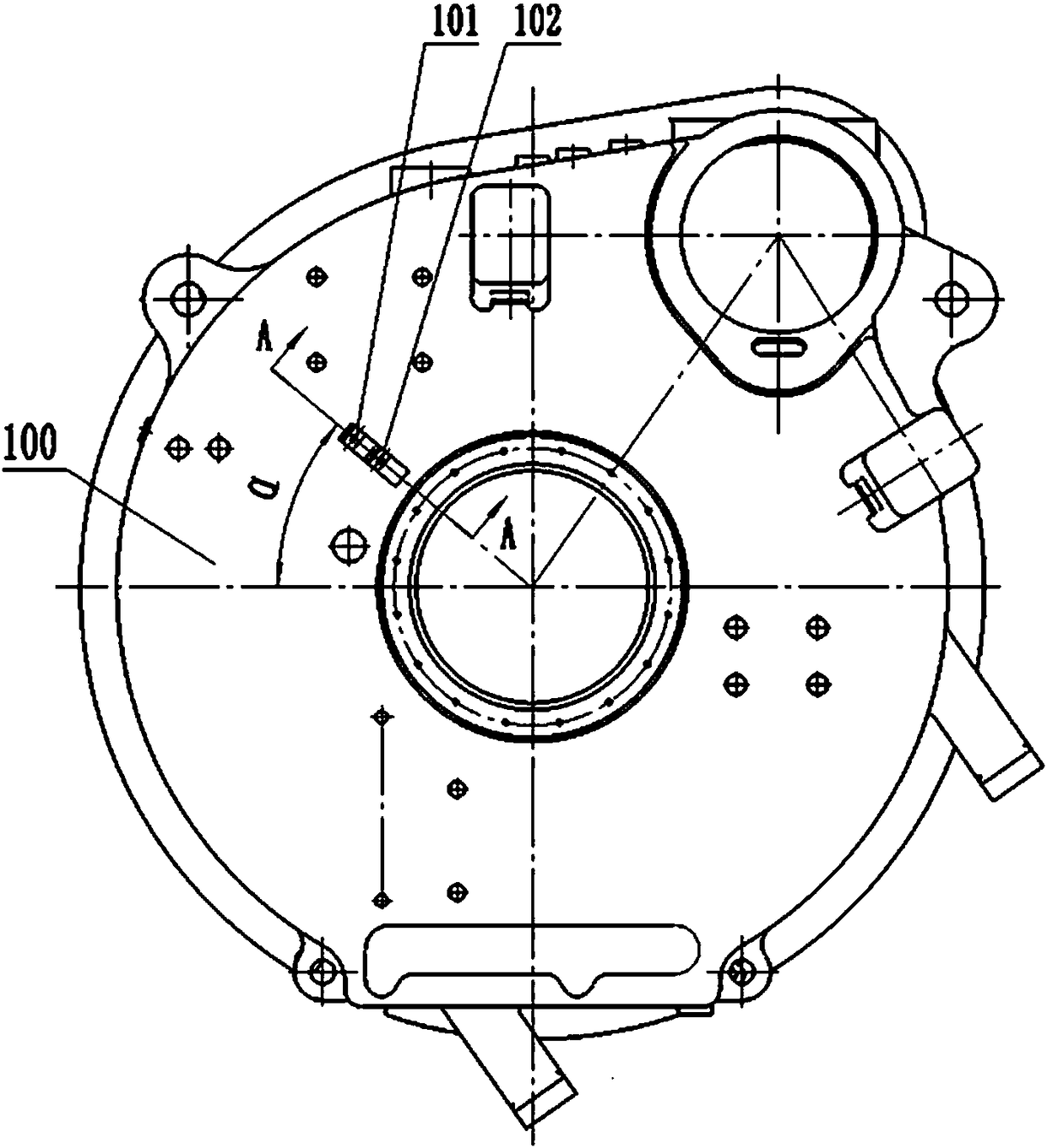

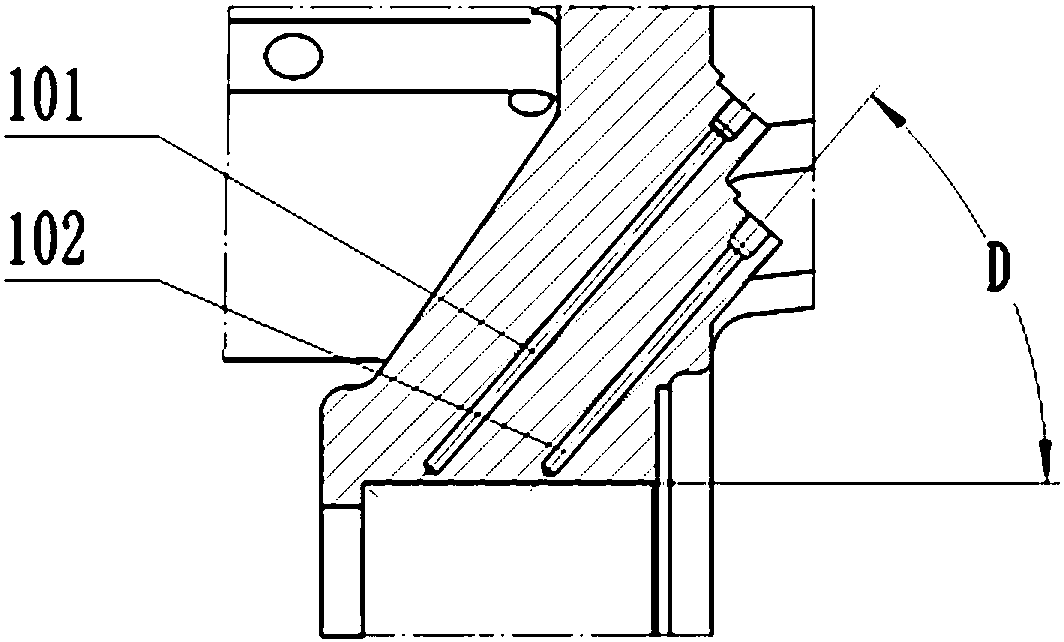

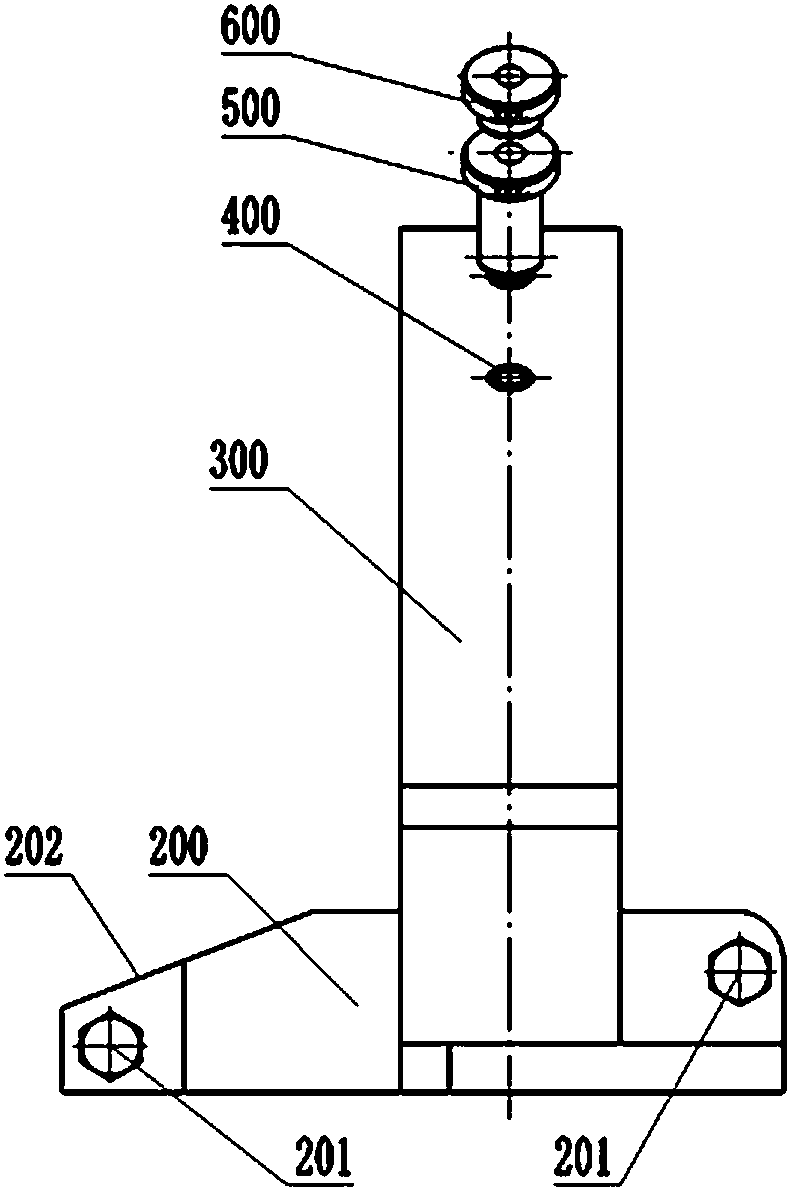

[0026] see Figure 3 to Figure 6 , the processing device for deep inclined holes in the upper space of a large wind power box of the present invention includes a connecting positioning plate 200, a guiding positioning plate 300, two bushings 400, a deep hole quick-change drill bushing 500 and a screw hole quick-change drill bushing 600; The connection positioning plate 200 is connected with the large-scale wind power box 100, and the inclined surface 202 at one corner corresponds to the inner arc E surface of the outer periphery of the installation surface A on the large-scale wind power box 100 (in this way, the inclined surface 202 can be When the present invention is in use, avoid interference between the straight face on the connection positioning plate 200 and the outer peripheral inner arc E surface of the mounting surface A on the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com