Novel welding operation platform

An operating platform and a new type of technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of welding quality inspection of items that cannot be welded, increasing the trouble of item transportation, and operation and movement of welding items. Achieve the effect of ensuring the use effect and use efficiency, improving the welding work efficiency, and improving the use function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

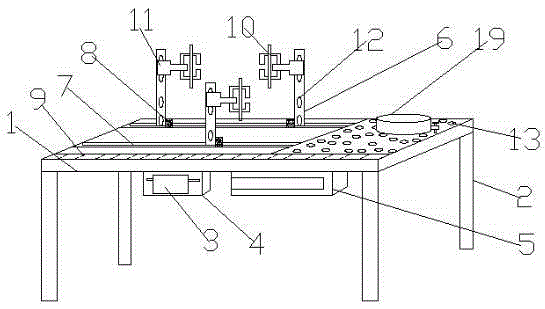

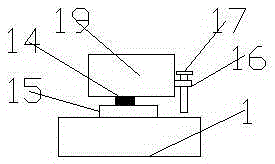

[0017] Example: see Figure 1-3 , The present invention is a new type of welding operation platform, including a workbench 1, the bottom of the workbench 1 is fixed with a support frame 2, the top of the workbench 1 is provided with a sliding frame 6 and a work fixture 10, the work fixture 10 One end is fixedly provided with a mounting frame 11, the surface of the sliding frame 6 is provided with mounting holes 12, the working clamp 10 and the sliding frame 6 are connected by bolts through the mounting frame 11 and the mounting holes 12, and the surface of the workbench 1 is provided with a placing slide The slot 7 and the working through hole 13, the sliding frame 6 is slidably connected with the placing chute 7, the bottom of the workbench 1 is fixedly connected with a placing box 4 and a welding tool placing box 5, and the placing box 4 is equipped with ultrasonic testing In instrument 3, a working turntable 19 is provided between the working through holes 13, a rotating sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap