High-precision small digital controlled lathe

A CNC lathe, high-precision technology, applied in the direction of automatic lathes/semi-automatic lathes, turning equipment, turning equipment, etc., can solve problems such as large contact area between slide table and guide rail, small size of lathe, and reduce processing efficiency, so as to improve processing accuracy and service life, high guiding accuracy, and improved vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

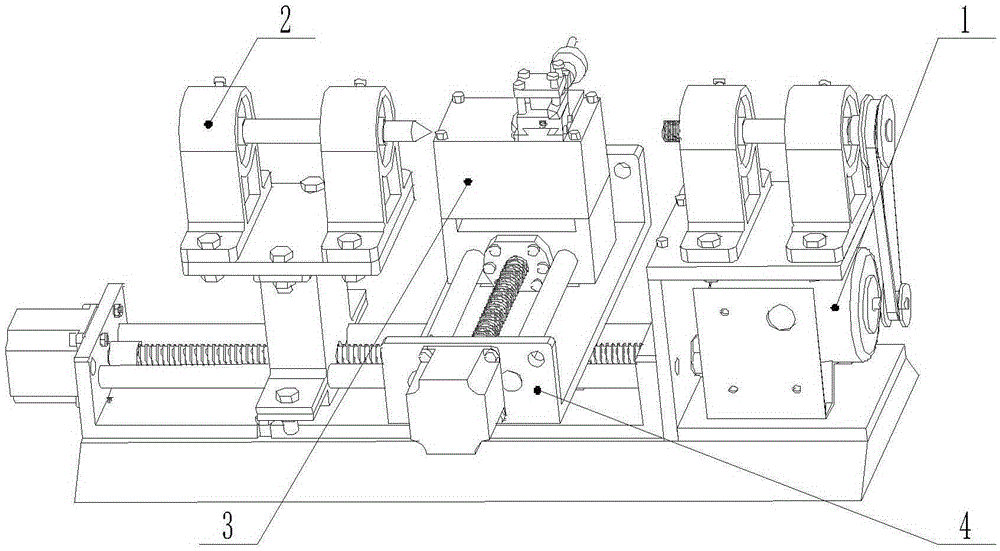

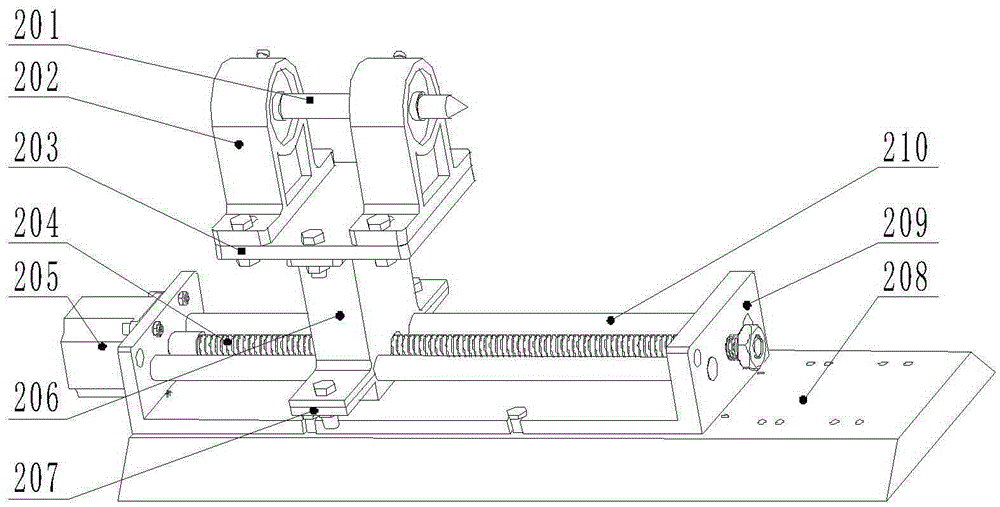

[0012] 1. See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the high-precision small CNC lathe provided by the present invention, the spindle motor base 104 in the spindle power mechanism 1 and the machine tool base 208 in the moving tailstock 2 are connected by bolts, and the lower ball screw 204 in the moving tailstock 2 is connected to the slide table 3 The lower lead screw nut 305 in the slide table 3 is connected by bolts, and the slide block 306 in the slide table 3 is connected with the knife rest cushion block 404 in the knife rest 4 by bolts.

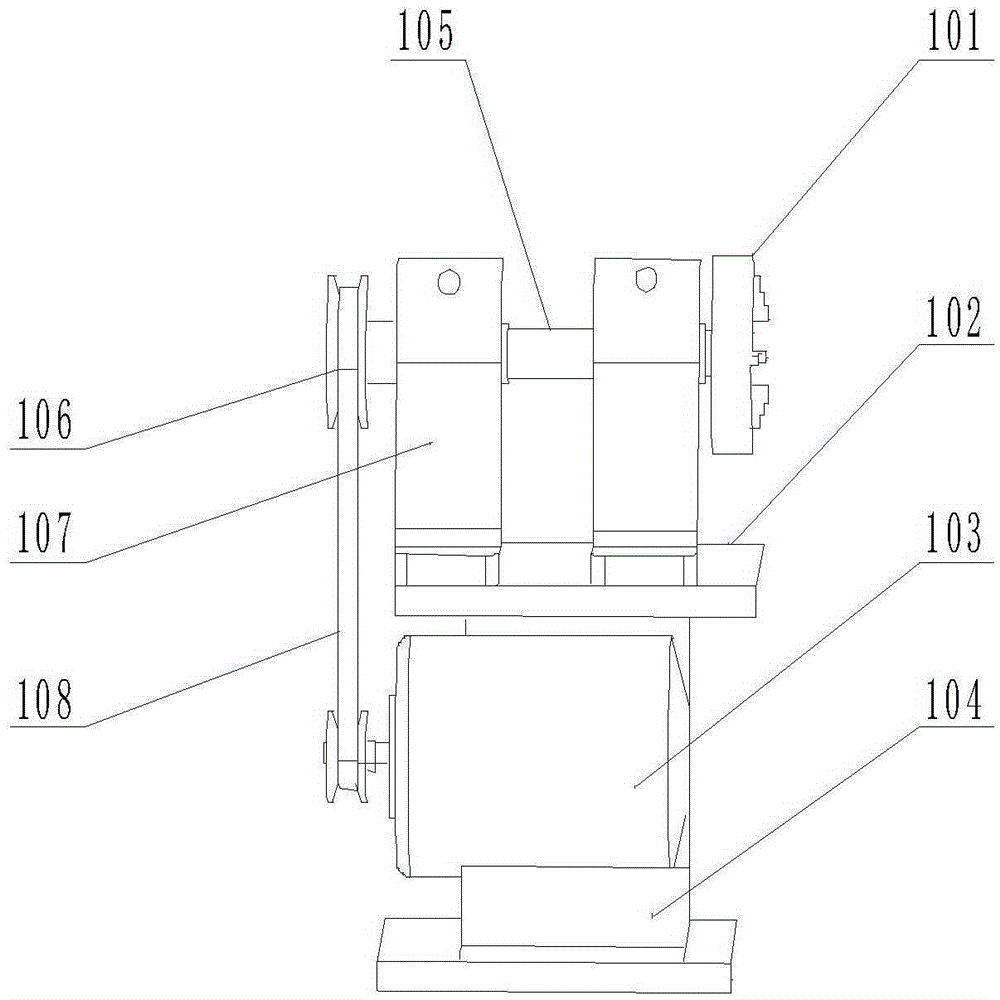

[0013] 2. If figure 2 As shown, the chuck 101 is connected to the main shaft 105 by bolts, the main shaft support pad 102 is connected to the main shaft motor base 104 by bolts, the main shaft motor 103 is connected to the main shaft motor base 104 by bolts, and the main shaft 105 is connected to the pulley 106 by bolts. The wheel 106 is connected to the main shaft motor 103 through a belt 108, the main shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com