Paper roll carrying trolley

A technology for handling trolleys and paper rolls, which is applied in trolleys, motor vehicles, multi-axle trolleys, etc. It can solve the problem that ordinary handling trolleys cannot meet the handling of paper rolls of different diameters, the material is easily deformed by edges, and the paper roll handling is not suitable. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

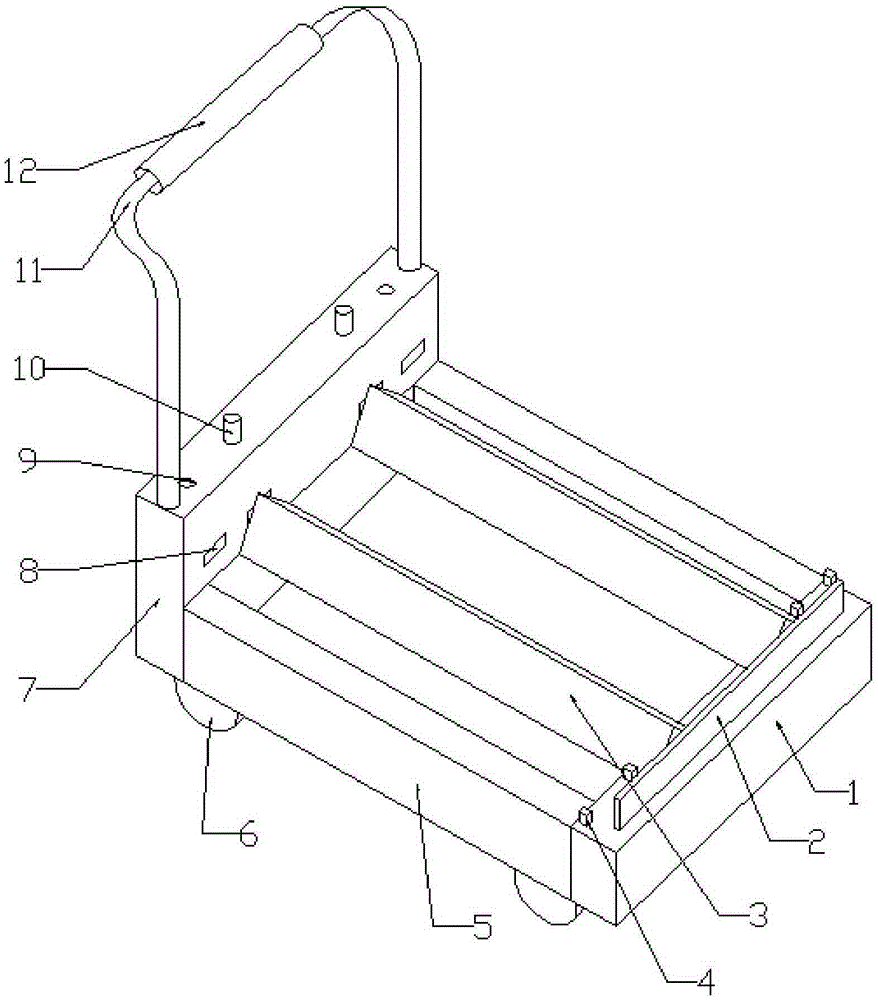

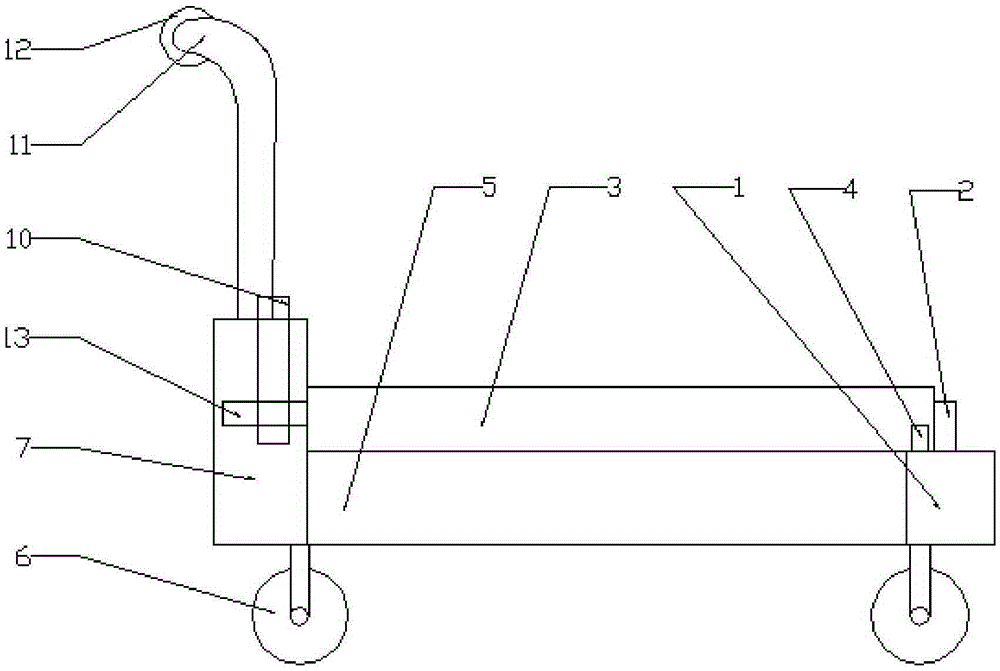

[0015] Such as figure 1 As shown, the present embodiment is a paper roll handling trolley, comprising a rectangular frame frame supporting the trolley, two sets of rollers below the chassis and a pair of triangular-shaped baffles 3 above the chassis; The frame includes a front horizontal frame one 1, a rear horizontal frame two 7 and left and right vertical frames 5; the top of the horizontal frame two 7 is provided with a handle 11; the handle 11 is covered with a rubber sleeve 12 for easy grip; The height of the second horizontal frame 7 is higher than that of the first horizontal frame 1; the side walls of the second horizontal frame 7 are provided with at least two pairs of mounting holes 8; The rear end is provided with a mounting plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com