Separate high-speed multi-speed transmission

A multi-speed transmission, separate technology, applied in the direction of vehicle gearbox, wheel transmission, transportation and packaging, etc., can solve the problems of not satisfying consumers, not being able to increase the speed of the vehicle, and slow riding speed, etc., to achieve a simple structure , Easy to use, easy shifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

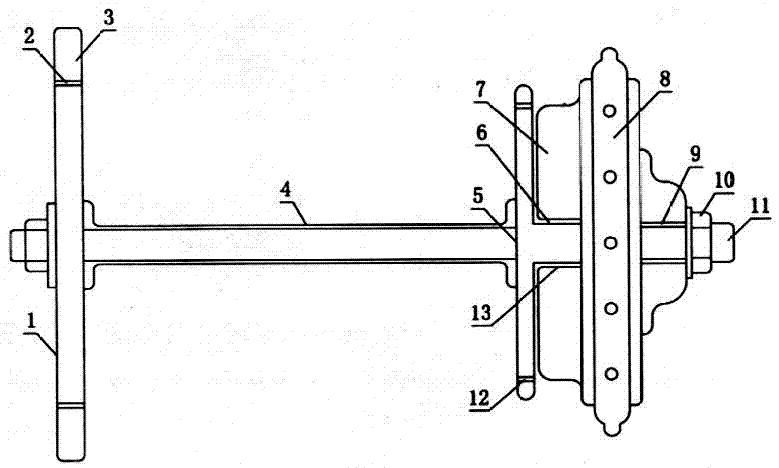

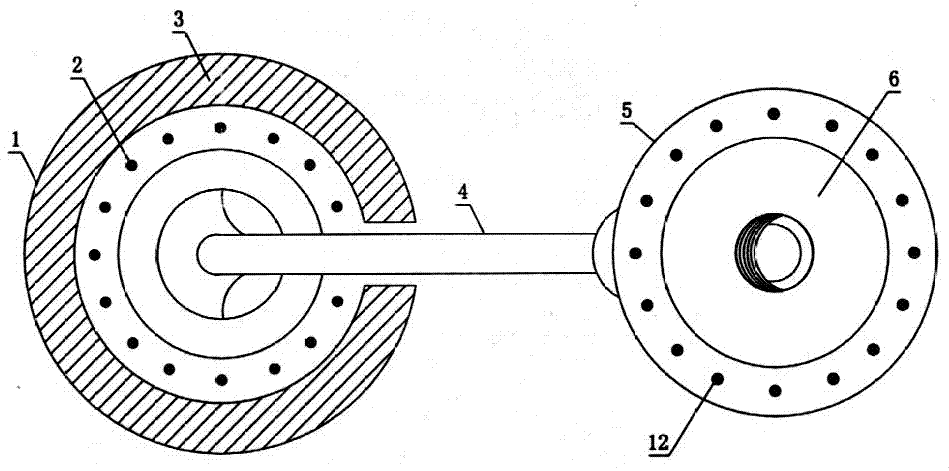

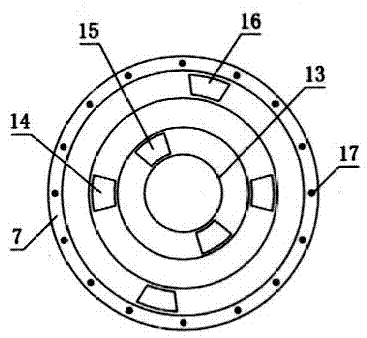

[0016] Figure 1-6 The right middle part of the right wheel hub 5 shown in is formed with a connecting sleeve 6, the connecting sleeve is provided with external thread, the right side of the right wheel hub is provided with a transmission disc 7, and the middle part of the transmission disc is provided with a screw hole 13, on the screw hole It is made with internal thread, and the transmission disc is fixed on the connecting sleeve of the right wheel hub by threaded connection. The right end face of the transmission disc is provided with a high-speed tooth groove 15, a medium-speed tooth groove 14, and a low-speed tooth groove 16 successively, and a ball groove 17 is provided on the circumference of the transmission disk. The right side of the drive disc is provided with a drive disc 8, and the left end face of the drive disc is successively provided with high-speed teeth 19 corresponding to the tooth grooves of the drive disc, medium-speed teeth 20, low-speed teeth 18, high,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com