Catapult

A catapult and tractor technology, which is applied in the direction of launch/drag transmission, can solve the problems of huge long-term investment in catapults, inability to launch drones, and high technical risks, so as to save structure and space resources, simple structure, and technical mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

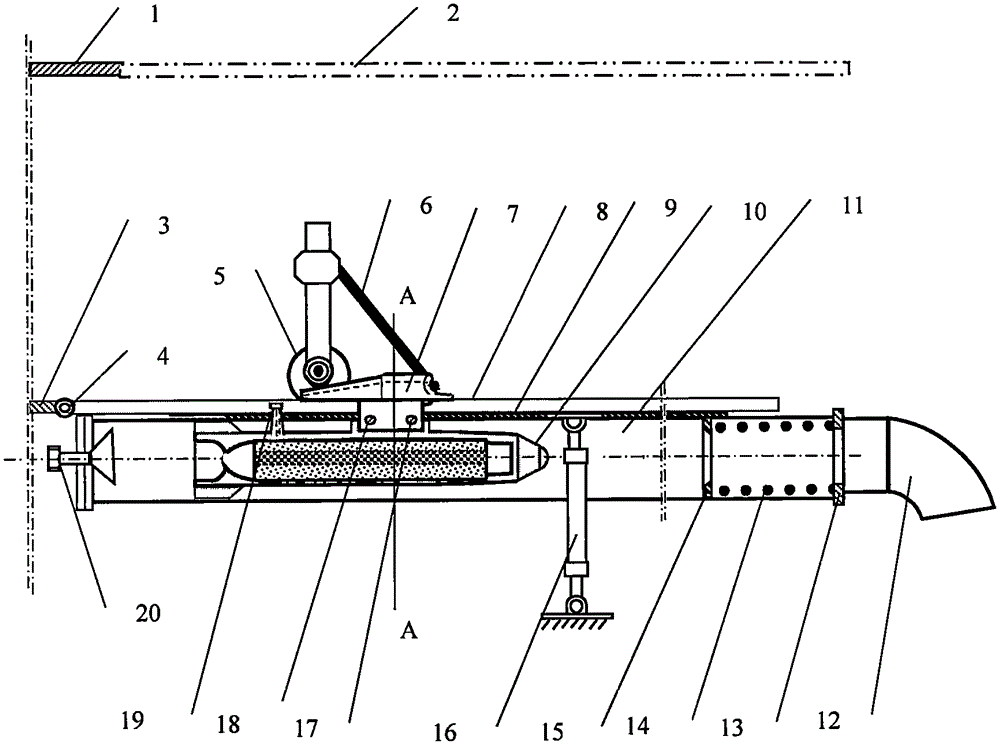

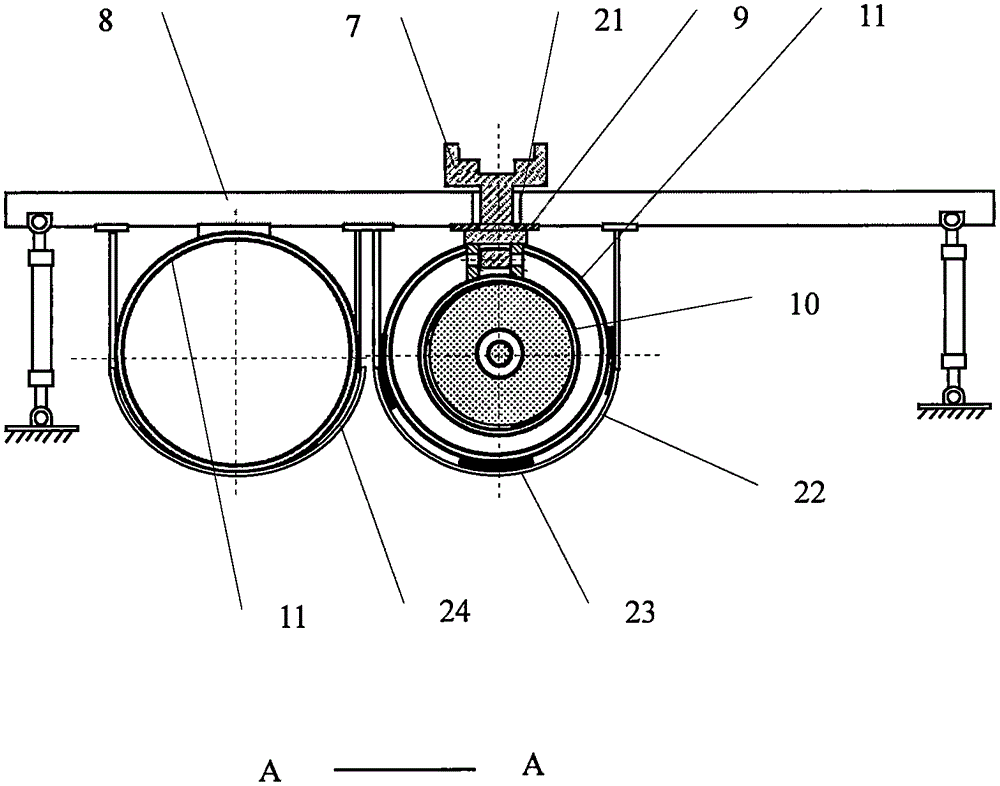

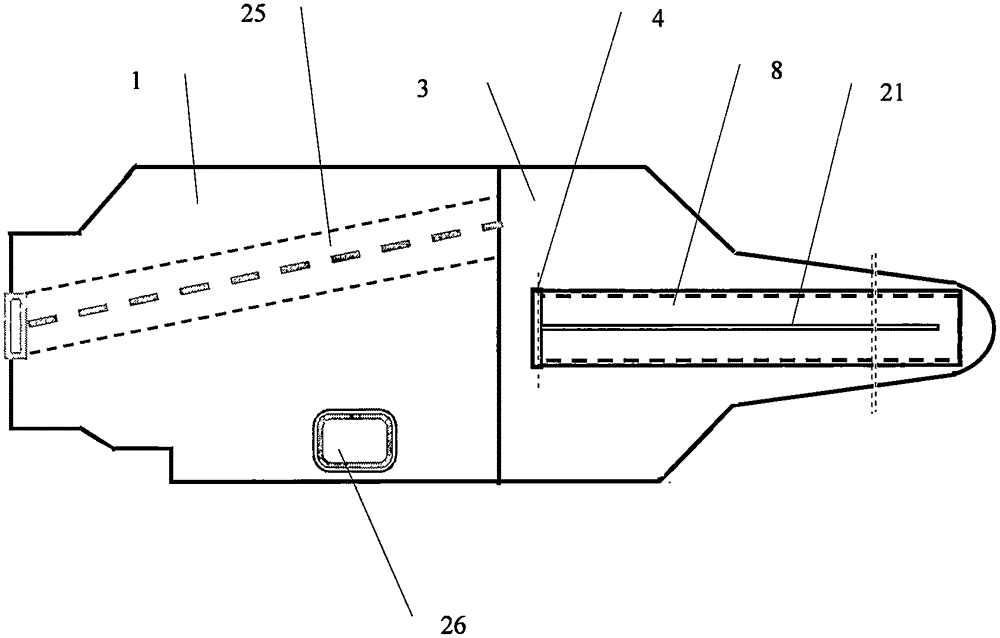

[0017] The catapult consists of an ejection track (8), a booster rocket (10), and a launching tube (11). The ejection track (8) is located at the carrier aircraft hangar front desk, in the same plane with the hangar floor (3), and the rear is connected with the hangar floor by a pin (4), and an ejection track groove (21) is arranged in the middle. Below is the rocket launcher (11), and the upper opening of the launcher is close to the track groove (21) and matches each other, and there is a sealing strip (9) therebetween. A slide block tractor (7) is arranged in the groove, and the part that the bottom stretches into the launching tube (11) has an arrow hanging device (17,18). When the aircraft is ejected, the tow bar (6) is hung before the slider tractor (7), and the booster rocket (10) injected with liquid propellant is ignited and launched, and the thrust is terminated after the aircraft takes off. The slide block tractor (7) and the launch tube (11) return to their origin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com