Anti-collision assembly type isolation strip device

An assembled, isolation belt technology, used in road safety devices, agricultural gas emission reduction, roads, etc., can solve the problems of limited anti-collision and buffering effects, easy spread of metal guardrails, high labor maintenance costs, and achieve good safety protection. effect, reduce labor maintenance costs, and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

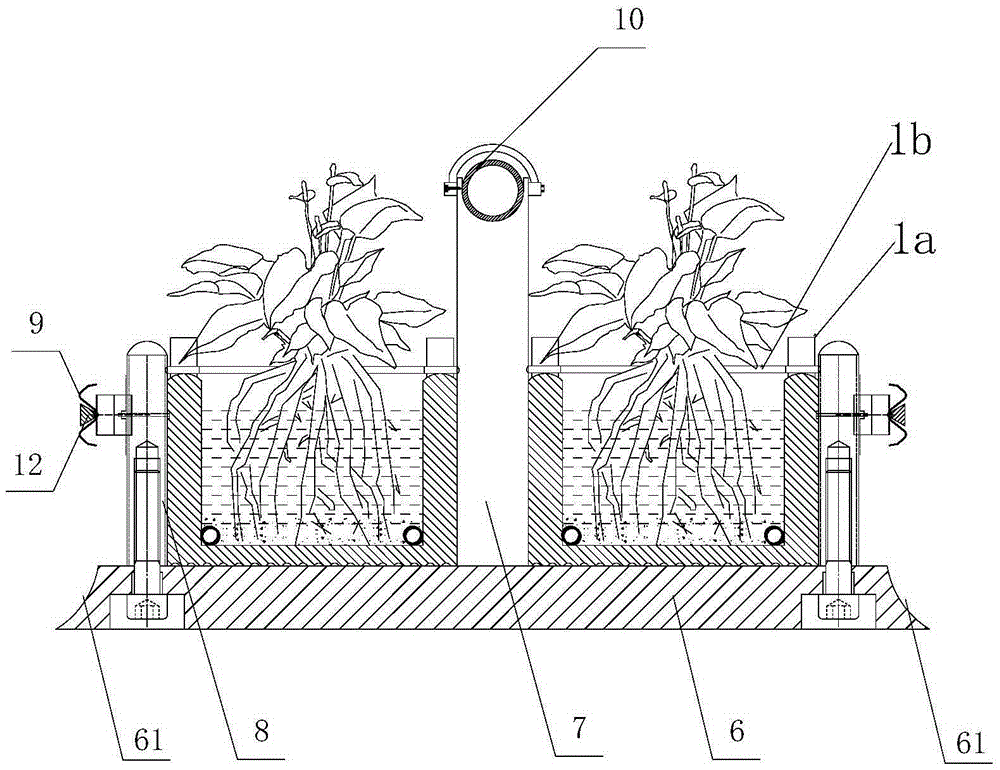

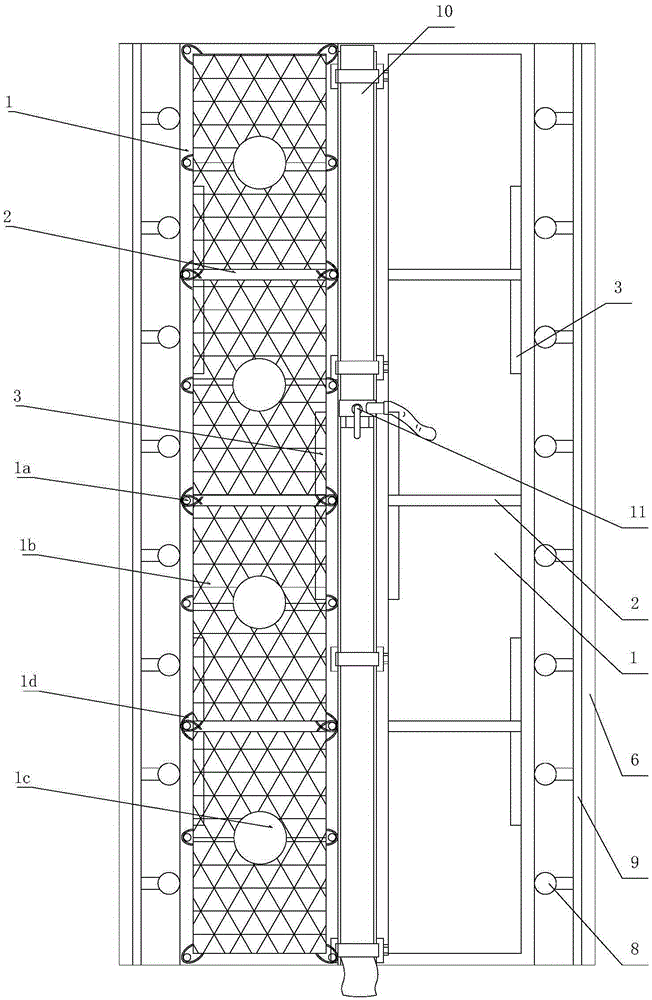

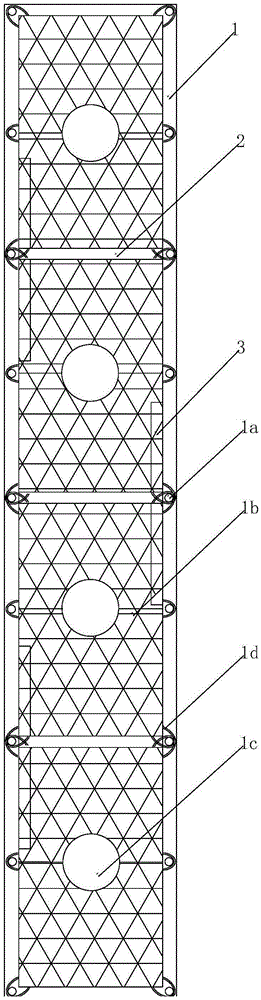

[0027] Such as Figure 1 to Figure 5 Shown: a kind of anti-collision assembled isolation belt device, its key lies in: including metal bottom plate 6, two outer guardrail combinations, neutral plate 7 arranged in parallel between the two outer guardrail combinations, the two sides of the metal bottom plate 6 It is an arc surface 61 concave inward, and the structure of the arc surface 61 passes through figure 1 It can be seen that the neutral plate 7 is welded in the middle of the metal base plate 6, and a bar-shaped water tank 1 is placed between the neutral plate 7 and the outer guardrail combination; the bar-shaped water tank 1 is equidistantly provided with partitions 2, and the partitions 2. Divide the bar-shaped water tank 1 into at least two water tanks, a water pipe 3 is connected between adjacent water tanks, the water pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com