a nut

A nut and nut body technology, applied in nuts, bolts, threaded fasteners, etc., can solve the problems of inadvertent disassembly, high cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

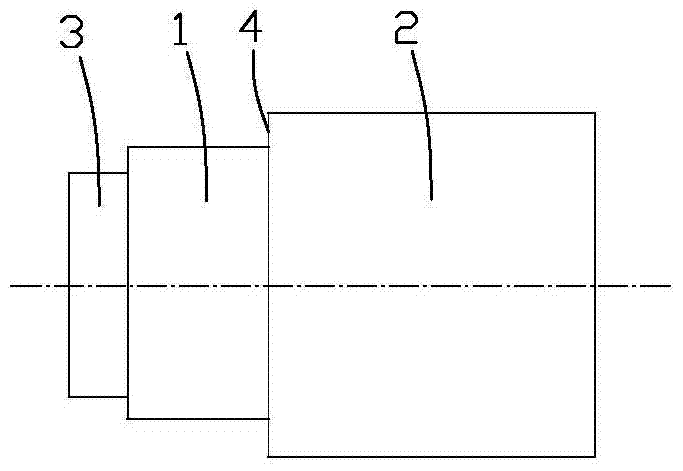

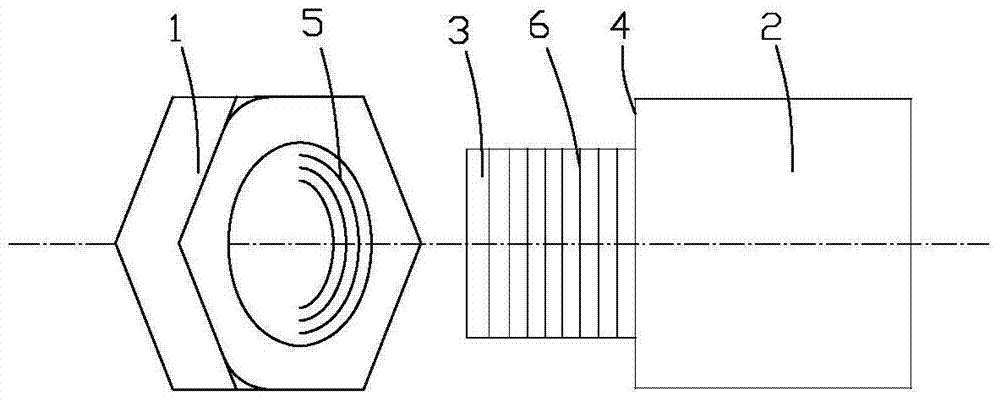

[0023] combine figure 1 and figure 2 As shown, a nut includes a nut body and a nut 1. The nut body is composed of front and rear sections, wherein, the nut body of the front section is represented by number 2, and the nut body of the rear section is represented by number 3.

[0024] Internal threads are provided on the front nut body 2 for connecting with bolts.

[0025] A limiting portion 4 is provided at the end of the front nut body 2 for blocking the nut 1 . The frontmost position of the nut 1 during movement can be limited by the limiting portion 4 . Specifically, the diameter of the limiting portion 4 is larger than the outer diameter of the rear nut body 3 .

[0026] An external thread 6 is provided on the rear nut body 3 . The external thread 6 matches the internal thread 5 provided on the nut 1, and the nut 1 and the rear nut body 3 are threadedly connected.

[0027] The nut 1 can adopt a hexagonal nut that is easy to cooperate with a wrench.

[0028] The nut ...

Embodiment 2

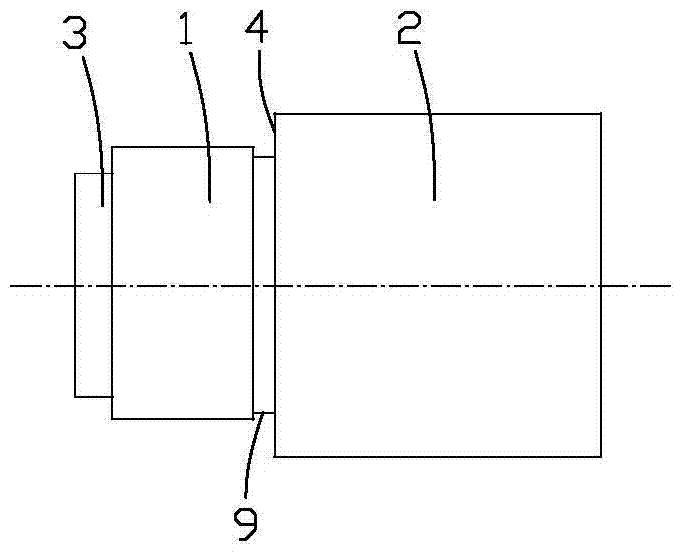

[0030] combine image 3 and Figure 4 As shown, except that the nut in the second embodiment is different from the first embodiment in the following technical features, other technical features can refer to the first embodiment above.

[0031] The rear nut body 3 includes a smooth section 7 and a threaded section 8 arranged in sequence from front to back. Wherein, the smooth section 7 is an unthreaded section, and the external thread 6 is arranged in the threaded section 8 .

[0032] The smooth section 7 acts as a force-relief area, and its function is to reduce the torque required for the separation between the nut 1 and the limiting part 4, thereby effectively preventing accidental disassembly between the bolt and the nut body.

[0033] Its general working principle is:

[0034] When the pipeline is connected, use a wrench to fasten the bolt and keep it in a static state, use another wrench to twist the nut 1 forward, and when the front end of the nut 1 is pressed against...

Embodiment 3

[0041] combine Figure 5 and Image 6 As shown, the nut in this embodiment 3 is different from that of embodiment 2 except for the following technical features, and other technical features can refer to the above embodiment 2.

[0042]The rear nut body 3 further includes a limiting segment 10 , and the limiting segment 10 is located on the rear side of the threaded segment 8 . Inside the limiting section 10, there is a nut anti-dropping part, which is used to prevent the nut 1 from slipping off due to wrong disassembly when the pipeline is installed vertically.

[0043] The anti-falling part of the nut includes a limit groove 11 and a limit ring 12 . The limiting slot 11 is provided on the limiting segment 10 , and the limiting slot 11 is arranged around the rear nut body 3 . The limiting ring 12 is adapted to the limiting groove 11 and installed in the limiting groove 11 .

[0044] The above-mentioned nut anti-dropping component has the advantages of simple structure, low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com