Two-channel air door structure used for fluid bed drying

A fluidized bed dryer, double-channel technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of not being able to connect or block at the same time, small application range of materials, unfavorable air flow control, etc., and achieve structural The effect of simplicity, shortened response time, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

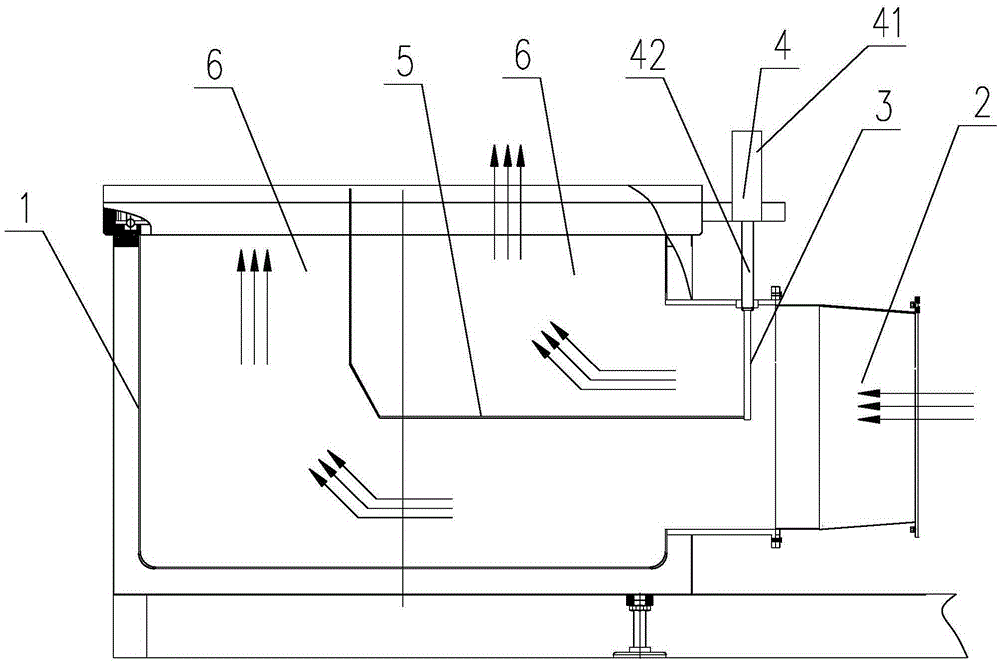

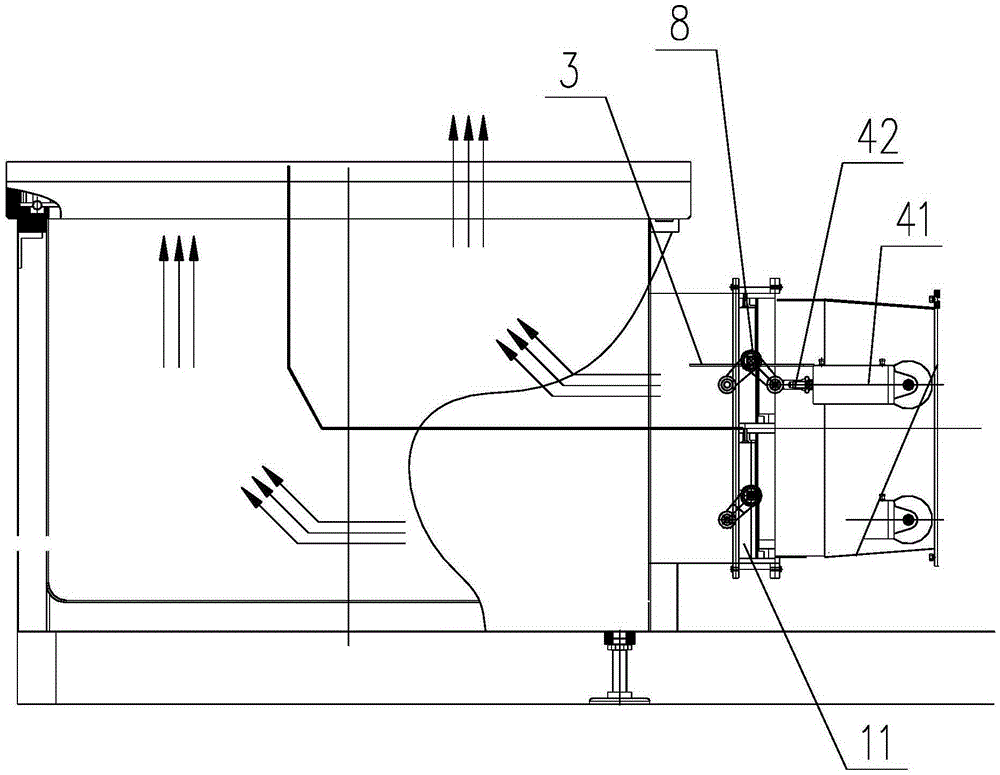

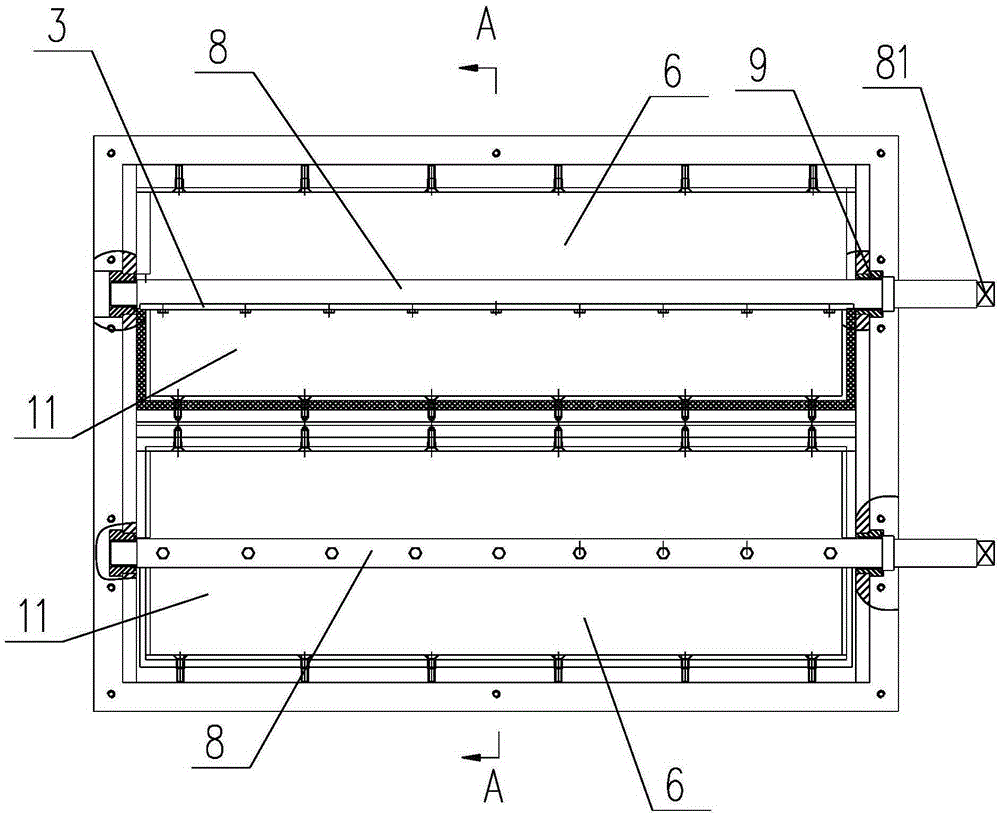

[0022] A double-channel damper structure for a fluidized bed dryer according to the present invention includes two damper door bodies 3 respectively arranged in two air inlet spaces 6, and a rotatable rotating shaft arranged on the cylinder body 1 of the machine base. 8. The driving mechanism 4 for driving the damper body 3 to rotate intermittently along the rotating shaft 8, each damper is provided with the rotating shaft 8 and the driving mechanism 4, and the base cylinder is provided with a shaft for installing the damper body 3, two hollow rectangular passages 11, the damper door body 3 is symmetrically arranged on the rotating shaft 8, the damper door body 3 is in a rectangular shape matched with the hollow rectangular passage 11, the damper and the hollow described The driving mechanism 4 is arranged outside the base cylinder, and a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com