A multi-unit intelligent manufacturing system with robots based on smart-rfid tags

An intelligent manufacturing, multi-unit technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of lack of intelligence, lack of flexibility, dispersion, etc., to reduce system response time and improve flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing.

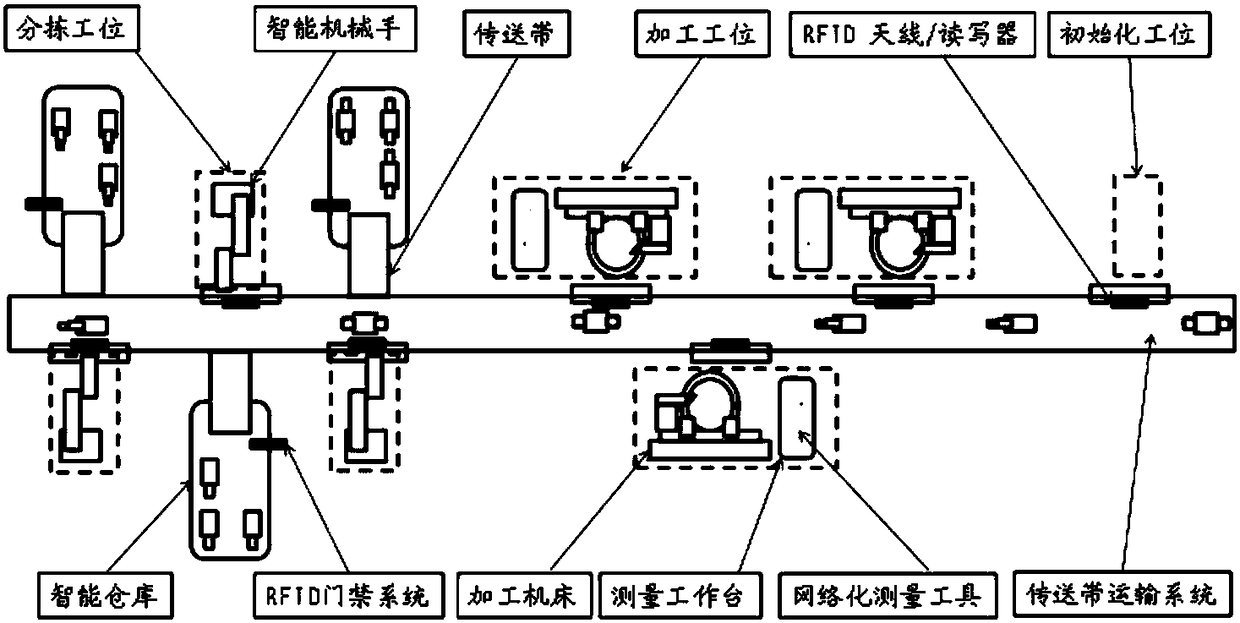

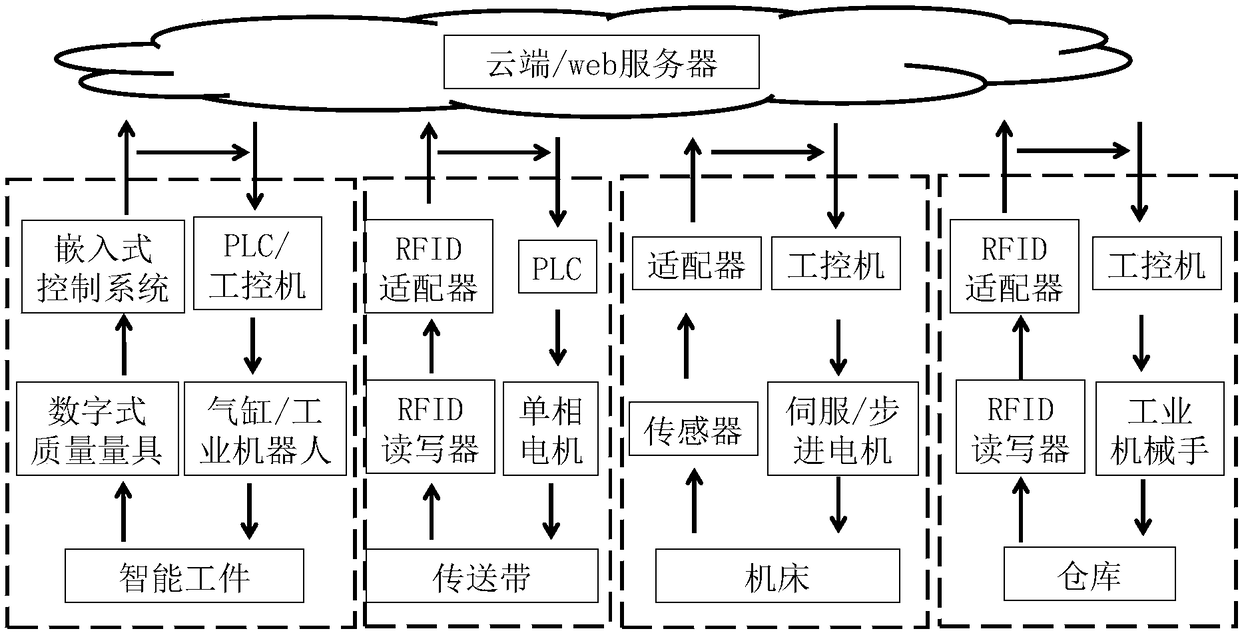

[0035] refer to figure 1 , a multi-unit intelligent manufacturing system with robots based on smart-RFID tags, including intelligent workpieces, initialization stations, processing stations, sorting stations, intelligent warehouses and conveyor belt transportation systems, where the processing stations are composed of processing machine tools and measuring Composition of workbench;

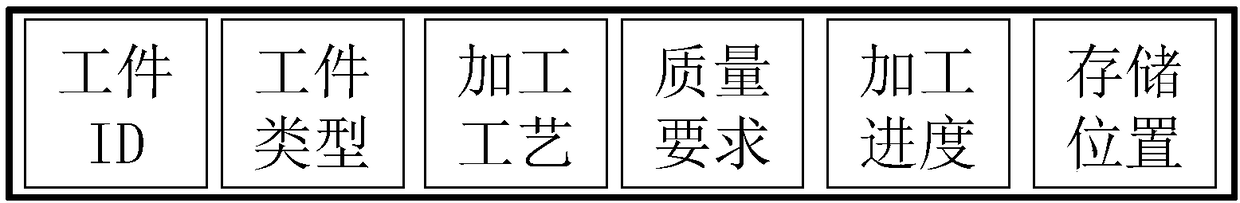

[0036] The smart workpiece is configured with a smart-RFID tag, and the information stored in the tag includes, refer to figure 2 : The ID code of the workpiece, the manufacturing process, the manufacturing process parameters, the quality characteristic requirements, the current processing status of the workpiece, the inventory location and the detailed manufacturing information table of the workpiece. These information are stored in the smart-RFID tag according to a certain structure to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com