Wind tunnel nozzle, active noise reduction device and method based on porous media

A porous medium, active noise reduction technology, applied in measurement devices, aerodynamic tests, testing of machine/structural components, etc., can solve the problems of high machining accuracy, high construction and maintenance costs, and inability to effectively reduce noise radiation, etc. To achieve the effect of eliminating noise radiation, easy to control the suction capacity, and conducive to quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

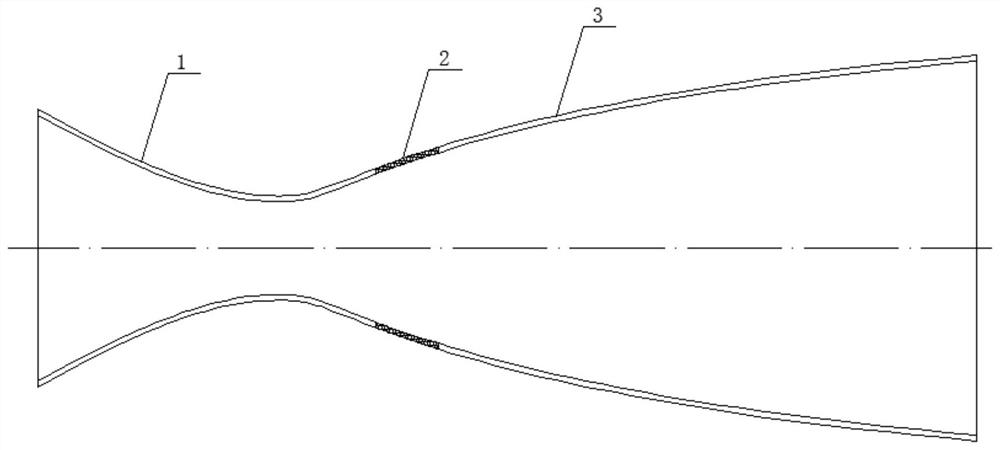

[0048] This embodiment provides a wind tunnel nozzle based on porous media, such as figure 1 As shown, the wind tunnel nozzle includes a wind tunnel nozzle converging section 1 , a porous medium section 2 and a wind tunnel nozzle diverging section 3 .

[0049] The starting position of the porous medium section 2 is located at the transition point of the laminar flow-turbulent boundary layer in the diverging section 3 of the wind tunnel nozzle. The downstream area of the tube is expanded; the porous material of the porous medium section 2 can be made of metal-based materials such as foamed aluminum and sintered copper to ensure that the wall surface of the porous treatment has sufficient strength; the porous medium section 2 and the wind tunnel nozzle expansion section 3 They can be bonded together with adhesives. The permeability of the porous medium section 2 is 0.01-10 Darcy.

[0050] When working, the high-pressure gas enters the wind tunnel nozzle from the tapering sec...

Embodiment 2

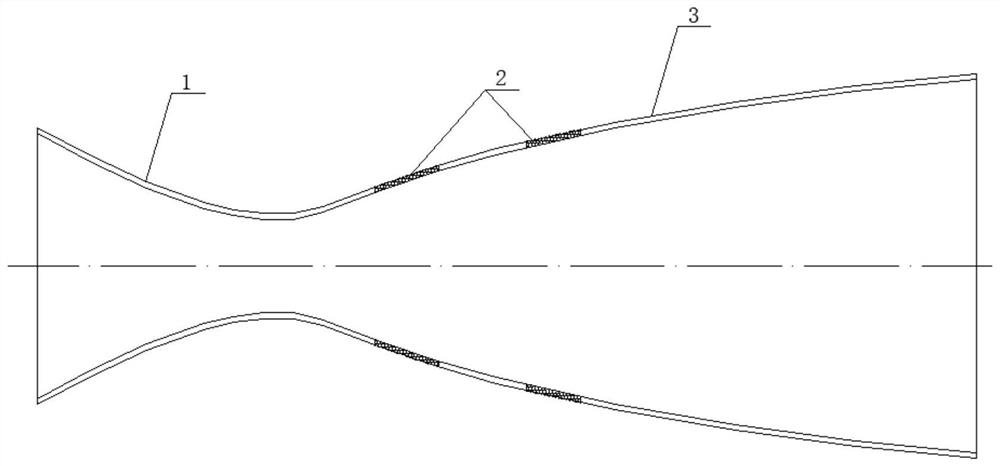

[0052] This embodiment provides a wind tunnel nozzle based on porous media, such as figure 2 As shown, the wind tunnel nozzle includes a wind tunnel nozzle converging section 1 , a porous medium section 2 and a wind tunnel nozzle diverging section 3 .

[0053] The porous medium 2 is arranged in multiple sections, and its starting position is located at the transition point of the laminar flow-turbulent boundary layer in the diverging section 3 of the wind tunnel nozzle. In order to further enhance the ability to control the suction gas in the boundary layer, the porous medium section 2 adopts a multi-section arrangement. figure 2 The medium porous medium section 2 is arranged in two sections, and the number of sections can be appropriately expanded during actual implementation.

[0054] In operation, the suction gas control method of the porous medium section 2 of the wind tunnel nozzle provided in this embodiment is consistent with that in Embodiment 1.

Embodiment 3

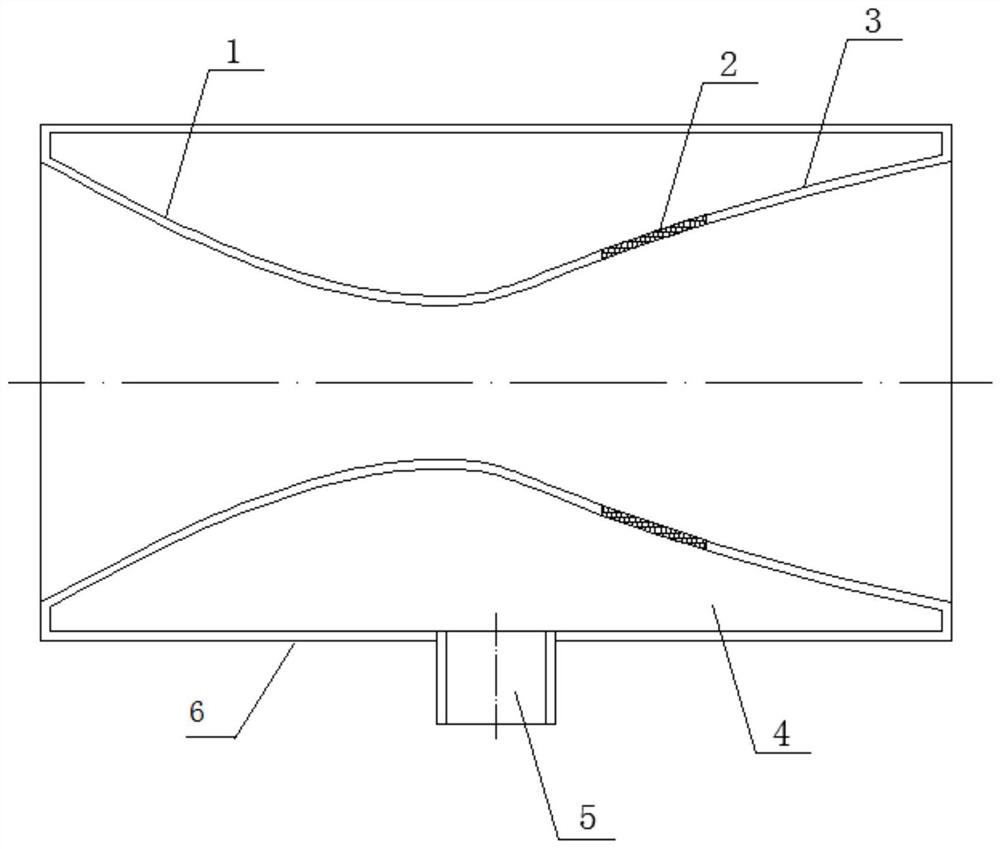

[0056] This embodiment provides an active noise reduction device based on porous media, which is a hypersonic wind tunnel wall active noise reduction device based on porous media suction flow control, such as image 3 As shown, it includes the wind tunnel nozzle of Embodiment 1 and the side wall 6 of the suction chamber.

[0057] The side wall of the suction chamber surrounds the outer circumference of the entire wind tunnel nozzle wall, and forms a suction chamber 4 with the wall of the wind tunnel nozzle. The side wall 6 of the suction chamber is provided with a suction outlet 5, and the suction chamber 4 Except the suction air outlet 5, other parts of the cavity are sealed. The permeability of the porous medium section 2 is 0.01-10 Darcy.

[0058] When working, the high-pressure gas enters the wind tunnel nozzle from the tapering section 1 of the wind tunnel nozzle and starts to accelerate, and reaches the speed of sound at the throat of the nozzle, and then further accele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com